Method for preparation of oligopeptides by solid state fermentation cake

A solid-state fermentation and oligopeptide technology is applied in the field of bioengineering to achieve the effects of uniform and convenient turning of materials, simple production process and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

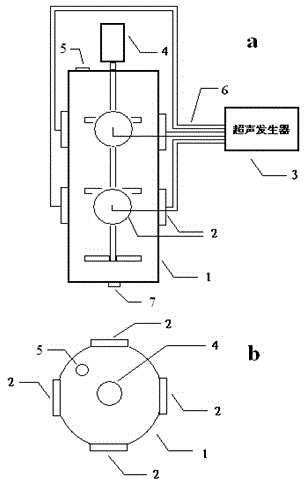

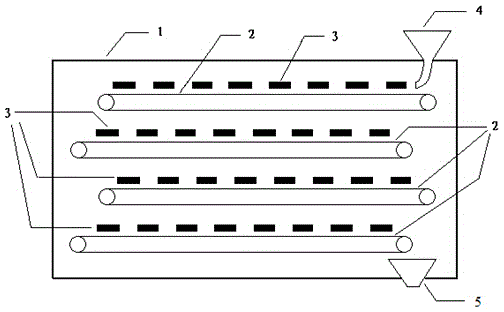

Embodiment 1

[0040] Take 100 kg of soybean meal and 100 kg of rapeseed meal, grind them through a 60-mesh sieve, and mix them for later use. Prepare seed liquid culture medium, its composition is peptone 1.0% (w / v), sodium chloride 0.5% (w / v), beef extract 0.3% (w / v), mix well, sterilize from the attached figure 1 Add the sterilized swept-frequency ultrasonic auxiliary culture tank 1 into the feeding port 5 and inoculate the activated Bacillus subtilis from the feeding port 5 Bacillus subtilis to the culture tank, control the culture temperature at 35°C, and adjust the attached figure 1In the ultrasonic working mode of the ultrasonic generator 3, the ultrasonic vibrator 2 is controlled by the wire 6, and the frequency-sweeping ultrasonic is used to assist cultivation for 24 hours, the ultrasonic frequency is 28kHz, and the sweeping frequency range is ±2kHz. Feed port 7 emits seed culture solution for subsequent use. Following the same procedure and medium recipe, use another swept-fre...

Embodiment 2

[0044] Take 100 kg of peanut meal and 100 kg of sunflower seed meal, grind them through an 80-mesh sieve, and mix them for later use.

[0045] Prepare seed liquid culture medium, its composition is the same as embodiment 1, after mixing, sterilizing, pour into sterilized frequency-sweeping ultrasonic auxiliary culture tank, inoculate activated Bacillus subtilis Bacillus subtilis Into the culture tank, 35 ℃ frequency sweep ultrasonic assisted cultivation for 36 hours, the ultrasonic frequency is 40kHz, and the sweep frequency range is ±0.5kHz. According to the same procedure and medium formula, use another frequency-sweeping ultrasonic-assisted culture tank for Aspergillus niger Aspergillus niger Ultrasound-assisted culture was carried out for 24 hours, the ultrasonic frequency was 20 kHz, and the scanning range was ±1.5 kHz. Inoculate and ferment after mixing at a volume ratio of 1:1. Inoculate the two seed culture solutions into the mixture of soybean meal and rapeseed me...

Embodiment 3

[0050] Take 100 kg of sesame meal and 100 kg of linseed meal, grind them through a 70-mesh sieve, and mix them for later use.

[0051] Prepare seed liquid culture medium, its composition is the same as that of Example 1, mix evenly, pour into sterilized frequency-sweeping ultrasonic-assisted culture tank after sterilization, inoculate activated Bacillus subtilis into the culture tank, 35 ℃ frequency-sweeping ultrasonic-assisted culture for 24 hours , Ultrasonic frequency 68kHz, sweep frequency range ± 2kHz. According to the same procedure and medium formula, another ultrasonic-assisted culture tank was used to conduct ultrasonic-assisted culture of Saccharomyces cerevisiae for 36 hours, with an ultrasonic frequency of 40 kHz and a frequency sweep range of ±1 kHz. .

[0052] Inoculate the two seed culture solutions into the mixture of soybean meal and rapeseed meal respectively according to the mass ratio of culture solution and cake 1:40, adjust the moisture content of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com