Method for macroscopically preparing high-quality graphene by using bio-mineralized material

A technology of biomineralization and graphene, applied in the field of materials, can solve the problems of unachieved graphene output, and achieve the effects of high yield, strong conductivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

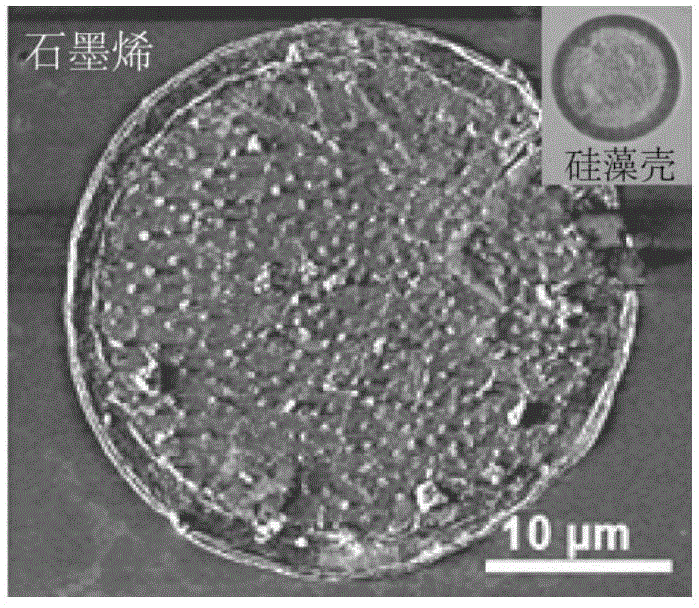

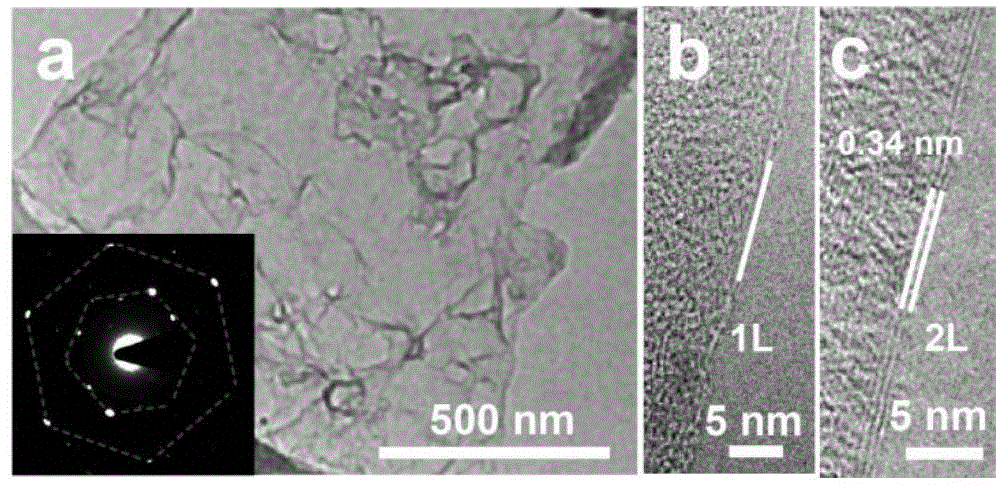

[0039] Embodiment 1, utilize diatomite to prepare graphene powder in large quantities as growth substrate

[0040] 1) Place diatomite in an atmospheric pressure chemical vapor deposition reaction furnace and pre-calcine at 800°C for 1 hour in an air atmosphere to remove residual organic matter and crystal water to obtain a silicon oxide phase with a stable structure;

[0041] 2) Heating the equipment to 1000°C at a heating rate of 5°C / min, and then passing methane under the protection of argon for reaction, methane is chemically adsorbed on the surface of pre-calcined diatomite as a gaseous reaction precursor, forming Nucleation and growth, the reaction time is 360min, the percentage of carbon source gas methane in the total volume of carbon source and carrier gas is 0.5%;

[0042] 3) The product after the reaction is added to a molar concentration of 0.1mol L -1 Soak in hydrofluoric acid or hydrofluoric acid / ethanol mixed solution for 600min, dissolve and corrode the diatomi...

Embodiment 2

[0046] Example 2, using shells as growth substrates to prepare graphene bionic macroscopic materials

[0047] 1) Place the scallop shell in an atmospheric pressure chemical vapor deposition reaction furnace and pre-calcine at 1000°C for 5 hours in an air atmosphere to remove residual organic matter and crystal water, and obtain a porous and structurally stable calcium oxide phase through pyrolysis;

[0048] 2) Continue to heat the reaction furnace to 1300°C at a heating rate of 100°C / min, and then feed methane under the protection of argon for reaction. Nucleation and growth, the reaction time is 10 minutes, the percentage of carbon source gas methane in the total volume of carbon source and carrier gas is 10%;

[0049] 3) the product after the reaction is placed in a molar concentration of 2mol L -1 Soak in the hydrochloric acid solution for 15 minutes, dissolve and corrode the shell material, and obtain the graphene macroscopic body imitating the shell shape soaked in the l...

Embodiment 3

[0052] Embodiment 3, utilize phytolith powder to prepare graphene powder in large quantities as growth substrate

[0053] 1) Put the phytolith powder in a low-pressure (vacuum degree of 133 Pa) chemical vapor deposition reaction furnace and pre-calcine at 800°C for 1 hour in an air atmosphere to remove residual organic matter and crystal water to obtain a silicon oxide phase with a stable structure;

[0054] 2) Continue to heat the reaction furnace to 900°C at a heating rate of 10°C / min, and then feed ethylene under the protection of nitrogen for reaction. Nucleation and growth, the reaction time is 120min, the carbon source gas ethylene accounts for 10% of the total volume of carbon source and carrier gas;

[0055] 3) The product after the reaction is added to a molar concentration of 1mol L -1 Soak in hydrofluoric acid or hydrofluoric acid / ethanol mixed solution for 600min, dissolve and corrode the silica powder, and obtain graphene in the liquid phase;

[0056] 4) After r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com