Back contact layer structure and CdTe solar battery comprising back contact layer structure

A solar cell, back contact technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as large diffusion coefficient and battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

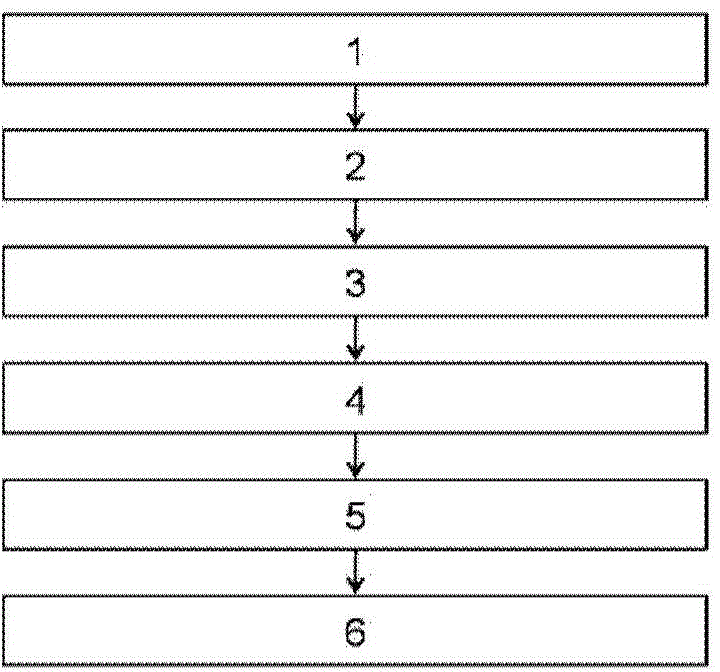

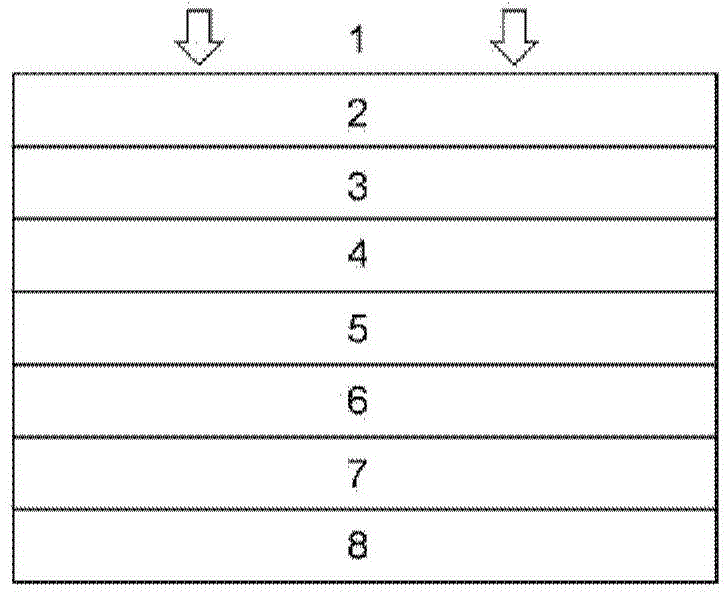

Method used

Image

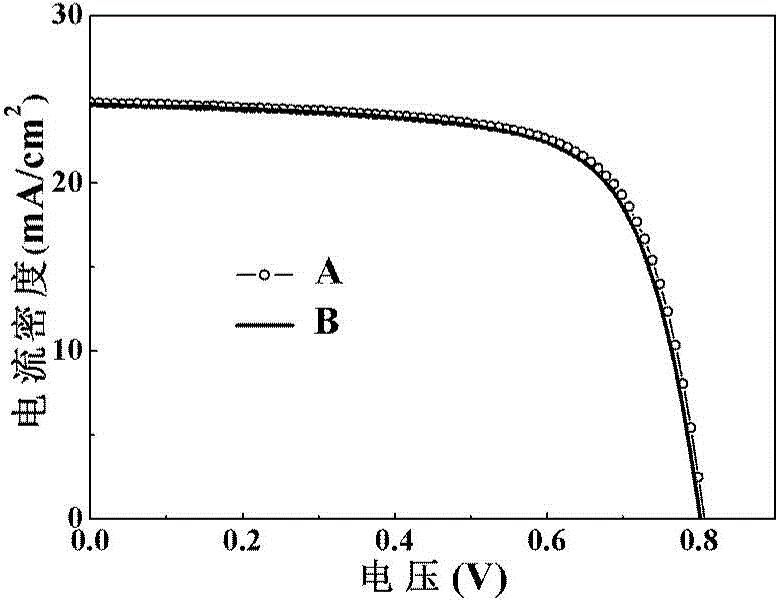

Examples

Embodiment approach 1

[0041] (1) Chemical etching of CdTe surface

[0042] Put the surface-cleaned glass / transparent conductive film / cadmium sulfide / cadmium telluride thin film structure sample into phosphoric acid nitric acid solution (volume ratio: nitric acid: phosphoric acid: water = 1:70:29) and etch for 5 to 50 seconds, etch After finishing, the sample surface was rinsed with deionized water, and then blown dry with N2.

[0043] (2) Deposition of Cu metal film

[0044] Put the etched sample into the vacuum chamber with a vacuum degree of 5×10 -6 Pa, using the electron beam evaporation method, deposited a 2nm thick Cu metal layer on the surface of the sample.

[0045] (3) Deposition V 2 o 5 film

[0046] The deposited Cu film samples were placed in the vacuum chamber of the magnetron sputtering instrument, and V 2 o 5 film. In the background vacuum (5×10 -3 Pa) under the condition, feed oxygen and argon into the system at the same time. The magnetron sputtering atmosphere is a mixed ...

Embodiment approach 2

[0048] (1) Chemical etching of CdTe surface

[0049] Put the glass / transparent conductive film / cadmium sulfide / cadmium telluride film structure sample with clean surface into bromine methanol solution (the volume ratio of bromine to methanol is 1:1000) and etch for 5 to 50 seconds, and use The surface of the sample was rinsed with deionized water and then washed with N 2 blow dry.

[0050] (2) Deposition of Cu metal film

[0051] Put the etched sample into the vacuum chamber with a vacuum degree of 5×10 -6 Pa, using the electron beam evaporation method to deposit a 1nm thick Cu metal layer on the surface of the sample.

[0052] (3) Deposition of MoO 3 film

[0053] Put the deposited Cu film sample into the vacuum chamber of the magnetron sputtering instrument, and use 4N pure MoO 3 Preparation of MoO by radio frequency sputtering on the target 3 film. In the background vacuum (5×10 -3 Pa) under the condition, feed oxygen and argon into the system at the same time. Th...

Embodiment approach 3

[0055] (1) Dry etching of CdTe surface

[0056] Place the glass / transparent conductive film / cadmium sulfide / cadmium telluride film structure sample with clean surface in vacuum (5×10 -3 Pa) conditions, using plasma beam (argon ion) bombardment method to remove excess CdCl on the surface 2 and oxides produced during heat treatment. The process is carried out in a pure argon atmosphere of 0.2-0.4Pa, and the bombardment power and beam current are related to the size of the sample area. The bombardment time is about 10 minutes.

[0057] (2) Deposition of Cu metal film

[0058] Put the etched glass / TCO / CdS / CdTe into a vacuum chamber with a vacuum degree of 5×10 -6 Pa, using the electron beam evaporation method, deposited a 1nm thick Cu metal layer on the surface of the sample.

[0059] (3) Deposition V 2 o 5 film

[0060] The sample of deposited Cu thin film was put into the vacuum chamber of thermal evaporation, and the purity of 99.95% V 2 o 5 The powder is used as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com