A 3D printed porous metal with bionic three-dimensional micro-stent and its preparation method

A three-dimensional, three-dimensional image technology, applied in the field of biomedical materials, can solve the problems of inability to achieve growth, limited bone extraction, and inability to achieve scaffold bone volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Preparation of titanium alloy-gelatin / HA three-dimensional micro-stent

[0056] Preparation of titanium alloy-gelatin / HA three-dimensional microscaffold:

[0057] 1) Import the CT image into Mimics or CAS 3D image software to obtain a 3D image of the target bone tissue, fill and expand the image with a regular dodecahedral structural unit with a pore column of 300um and a pore diameter of 1500um, and obtain a personalized porous connected 3D image digital model;

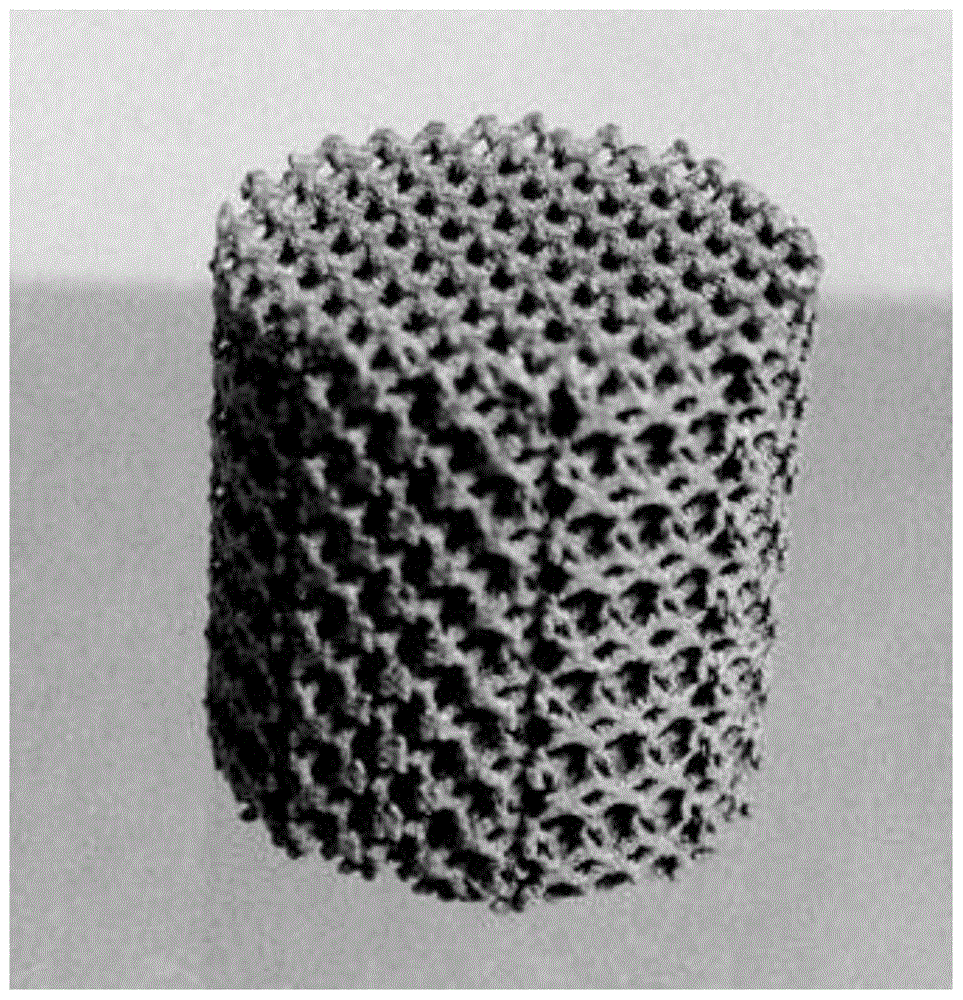

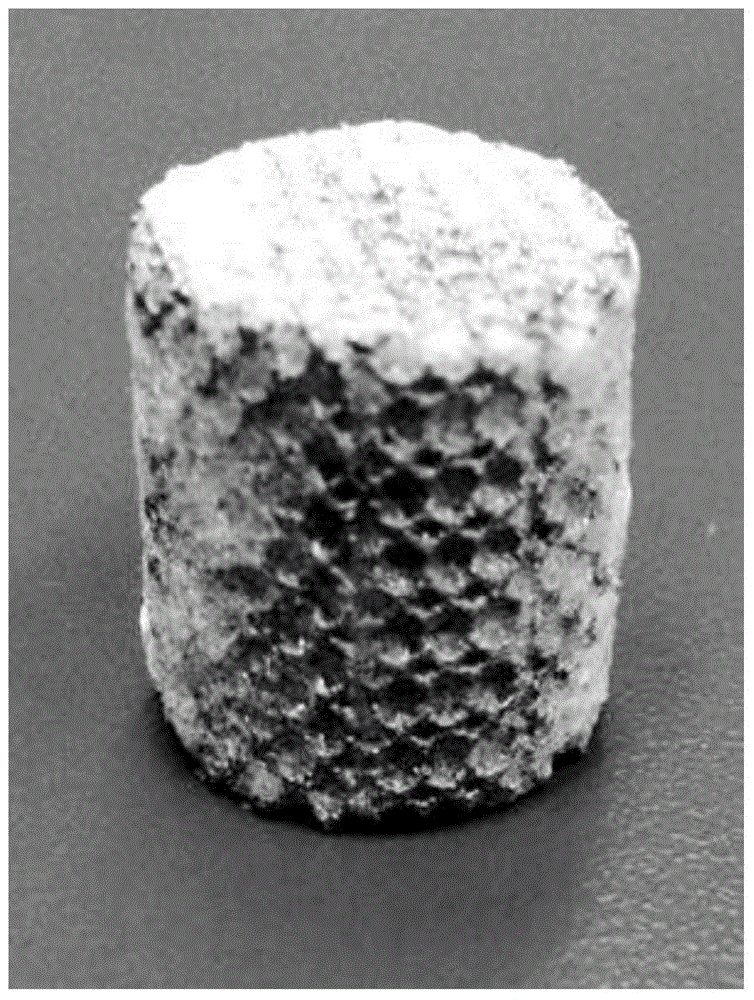

[0058] 2) Using EOS M280 metal material 3D printer, using titanium alloy as raw material, printing porous titanium scaffold according to the design model (see figure 1 );

[0059] 3) Add gelatin particles into deionized water at a ratio of 5%, and dissolve them completely in a magnetic stirrer at 37°C and 300r / min;

[0060] 4) Add nano-hydroxyapatite powder nHA to the gelatin solution at a ratio of 1:2 between nHA and gelatin, and use an ultrasonic cell pulverizer to disperse the mixture to a homo...

Embodiment 2

[0065] The characterization of embodiment 2 three-dimensional micro-stent

[0066] 1. Determination of porosity of three-dimensional micro-scaffolds

[0067] The porosity of the artificial bone scaffold was measured by the modified liquid displacement method. Put absolute ethanol with a volume of V1 into the graduated cylinder, put the three-dimensional artificial bone scaffold material into the graduated cylinder, suck air under negative pressure after Smin, so that the absolute alcohol is completely filled in the gaps of the scaffold material, record the volume at this time as VZ, then take out the material and record the volume of alcohol at this time as Vs. Calculate the porosity of the three-dimensional bionic artificial bone scaffold according to the following formula:

[0068] Porosity=(V1-V3) / (V2-V3)×100%

[0069] 2. Mechanical performance analysis of three-dimensional micro-stents

[0070] The compressive mechanical properties of the scaffold materials were measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com