A kind of preparation method of superhydrophobic copper foil

A technology of super-hydrophobic surface and copper foil, which is applied to the device for coating liquid on the surface, metal material coating process, special surface, etc., can solve the problems of poor stability, achieve stable performance maintenance, good reproducibility, prevent snow sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

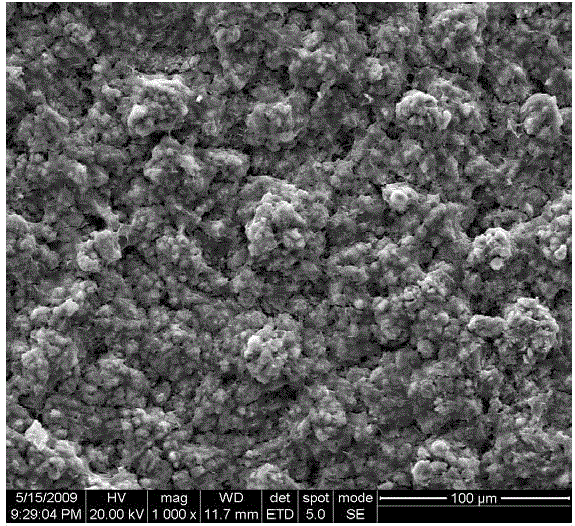

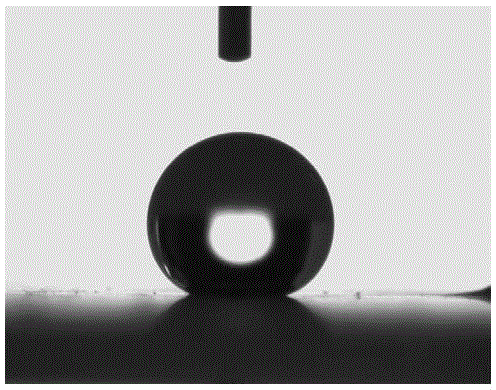

Image

Examples

Embodiment 1

[0028] Step 1. Cut copper foil with appropriate length and width.

[0029] Step 2. Rinse off the dust on the copper foil surface with deionized water.

[0030] Step 3: Soak the copper foil in ethanol and acetone for 25 minutes, then take it out and dry it.

[0031] Step 4: Soak the copper foil in glacial acetic acid solution for 10 hours, the temperature of glacial acetic acid is 20°C.

[0032] Step 5: Soak the copper foil soaked in 25% glacial acetic acid in 15% hydrogen peroxide for 1 hour at a temperature of 40°C.

[0033] Step 6. Soak the copper foil soaked in hydrogen peroxide for 5 hours in a 2% potassium permanganate solution by mass, and the soaking temperature is 20°C.

[0034] Step 7, dissolving stearic acid in ethanol to form a solution with a concentration of 1% by mass.

[0035] Step 8. Put the copper foil soaked in the potassium permanganate solution in the stearic acid solution prepared in step 7 and soak for 30 minutes, then take it out and dry it to obtain ...

Embodiment 2

[0037] Step 1. Cut copper foil with appropriate length and width.

[0038] Step 2. Rinse off the dust on the copper foil surface with deionized water.

[0039] Step 3: Soak the copper foil in ethanol and acetone for 30 minutes, then take it out and dry it.

[0040] Step 4: Soak the copper foil in a 30% by mass glacial acetic acid solution for 0.5 hour, and the temperature of the glacial acetic acid is 60°C.

[0041] Step 5: Soak the copper foil soaked in glacial acetic acid in 5% hydrogen peroxide for 5 hours at a temperature of 20°C.

[0042] Step 6. Soak the copper foil soaked in hydrogen peroxide for 5 hours in a solution of 1% potassium permanganate by mass, and the soaking temperature is 80°C.

[0043] Step 7, dissolving stearic acid in ethanol to form a solution with a concentration of 5% by mass.

[0044]Step 8. Put the copper foil soaked in the potassium permanganate solution in the stearic acid solution prepared in step 7 and soak for 40 minutes, then take it out a...

Embodiment 3

[0046] Step 1. Cut copper foil with appropriate length and width.

[0047] Step 2. Rinse off the dust on the copper foil surface with deionized water.

[0048] Step 3: Soak the copper foil in ethanol and acetone for 30 minutes, then take it out and dry it.

[0049] Step 4: Soak the copper foil in a glacial acetic acid solution with a concentration of 35% by mass for 5 hours, and the temperature of the glacial acetic acid is 25°C.

[0050] Step 5. Soak the copper foil soaked in glacial acetic acid in 10% hydrogen peroxide for 3 hours at a temperature of 50°C.

[0051] Step 6: Soak the copper foil soaked in hydrogen peroxide for 1 hour in a 5% potassium permanganate solution at a temperature of 50°C.

[0052] Step 7, dissolving stearic acid in ethanol to form a solution with a concentration of 1% by mass.

[0053] Step 8. Put the copper foil soaked in the potassium permanganate solution in the stearic acid solution prepared in step 7 and soak for 30 minutes, then take it out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com