Denitrifying bacterium and fermenting production method thereof

A technology of denitrifying bacteria and production methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of high energy consumption, cumbersome industrial fermentation procedures, low optimal temperature, etc., and achieve simple fermentation process , high live bacteria content and spore rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

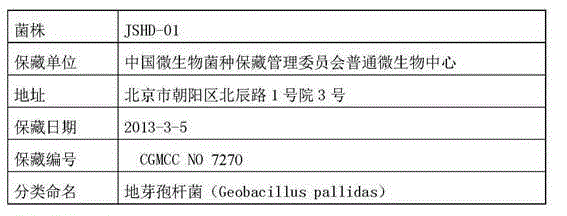

[0018] The screening steps of JSHD-1 denitrifying bacteria of the present invention are as follows:

[0019] (1) Sample collection

[0020] The produced fluids of 3 oil wells were collected in Jiangsu Oilfield, and the sample names were: Fu 129, Fu 137, and Fu 146.

[0021] (2) Culture medium configuration

[0022] The enrichment medium is composed of A solution and B solution, in which:

[0023] Solution A: 2.0 g inorganic salt K1, 1.0 g asparagine, 500 ml distilled water, pH 7.0~7.2;

[0024] Solution B: 8.5 g sodium citrate, 2 g sodium acetate, 2 g glucose, KH 2 PO 4 0.5 g, K 2 HPO 4 0.5 g, MgSO 4 ·7H 2 O 1.0 g, FeCl 3 ·6H 2 O 0.05 g, CaCl 2 0.1 g, yeast extract 0.5 g, distilled water 500 ml. The pH value is 7.0~7.2.

[0025] NRB liquid medium: liquid A and liquid B are sterilized separately at 121 ℃ for 20 min, and mixed in equal proportions after sterilization.

[0026] NRB solid medium: add agar with a mass ratio of 1.5% to 2% to liquid A and liquid B, a...

Embodiment 2

[0065] (1) Inoculate CGMCC NO 7270 strains on 3 eggplant bottles filled with solid medium. The solid medium formula and the mass percentage of each component are: sodium nitrate 0.2%, sodium acetate 0.1%, potassium dihydrogen phosphate 0.1%, glucose 0.1%, magnesium sulfate 0.02%, aspartic acid 0.05%, ferric chloride 0.01%, yeast extract 0.012%, agar 2.0%, the balance is water, pH value 7.0. The inoculated solid medium was cultured statically in a 60°C incubator for 3 days to form denitrifying bacterial spores.

[0066] (2) Wash the surface of the solid medium with sterile water to obtain 250mL of denitrifying bacterial spore suspension, and the content of spores counted by microscope hemocytometer is 2.7×10 10 cfu / mL.

[0067] (3) The above-mentioned spore suspension was pretreated in a 70°C water bath for 10 minutes, and then inoculated into the sterile medium of a 10,000L fermenter. The medium formula and the mass percentages of each component were: sodium nitrate 0.2%, so...

Embodiment 3

[0069] (1) Inoculate CGMCC NO 7270 strains on 3 eggplant bottles filled with solid medium. The solid medium formula and the mass percentage of each component are: sodium nitrate 0.2%, sodium acetate 0.1%, potassium dihydrogen phosphate 0.1%, glucose 0.1%, magnesium sulfate 0.02%, aspartic acid 0.05%, ferric chloride 0.01%, yeast extract 0.012%, agar 2.0%, the balance is water, pH value 7.0. The inoculated solid medium was cultured statically in a constant temperature incubator at 50°C for 4 days to form denitrifying bacterial spores.

[0070] (2) Wash the surface of the solid medium with sterile water to obtain 250 mL of denitrifying bacterial spore suspension, and the content of spores counted by microscope hemocytometer is 3.5×10 10 cfu / mL.

[0071] (3) The above-mentioned spore suspension was pretreated in a 70°C water bath for 10 minutes, and then inoculated into the sterile medium of a 10,000L fermenter. The medium formula and the mass percentages of each component were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com