A kind of treatment method of coal chemical industry wastewater

A technology of coal chemical waste water and treatment method, applied in the field of coal chemical industry, can solve the problems of high operation cost, difficult to meet the standard of treatment, complicated operation, etc., and achieve the effects of good treatment effect, strong practicability and simple management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

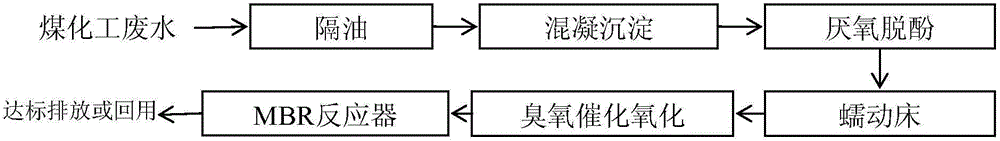

[0029] Such as figure 1 Shown, the present invention provides a kind of treatment method of coal chemical industry wastewater, comprises the following steps:

[0030] The invention provides a treatment method for coal chemical wastewater, comprising the following steps:

[0031] 1) The wastewater that needs to be treated removes suspended coal tar through the gravity oil separation method;

[0032] 2) Use 30-50mg / L coagulant PAC (polyaluminum chloride, commercially available) or PAM (polyacrylamide, commercially available) to coagulate and settle to remove fine suspended solids and emulsified oily substances in wastewater, and the settling time 0.5-1.0h;

[0033] 3) The effluent after coagulation and sedimentation enters the UASB anaerobic reactor for anaerobic dephenolization treatment. Oxygen dephenolization treatment is added with anaerobic dephenolization bacteria ZHB655 (purchased from Beijing Zhongheng Huitong Environmental Technology Co., Ltd.), and the dosage is 0....

Embodiment 2

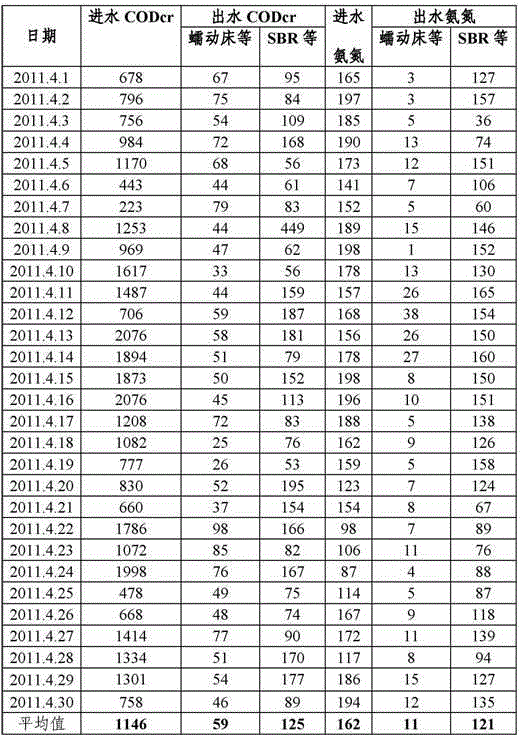

[0039] Embodiment 2 processing method of the present invention and SBR effect comparative test

[0040]In order to verify the effect of the treatment method described in the present invention, under the same condition of influent water quality, we adopted the treatment described in the present invention on April 1, 2011 at the waste water treatment site of Ningxia Shenhua Coal DME plant The method was compared with the treatment method dominated by activated sludge method SBR for a period of one month (see Table 1). L, ammonia nitrogen is less than 15mg / L. Wherein, the designed treatment water volume Q=30L / h of the treatment method of the present invention, effective hydraulic retention time is 6.6 hours, all the other process conditions are the same as embodiment 1, and the main process conditions of comparative process (SBR+Fenton oxidation) are set as: The operation cycle of SBR single tank is 8 hours, and the sludge load is 0.2KgBOD 5 / (KgMLSS·d); the concentration of hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com