A kind of mountain palm jute composite mattress

A technology of mountain brown jute and mattress, applied in the field of fiber materials, can solve the problems of comfort and environmental protection, the service life of antibacterial and ventilation needs to be improved, etc., and achieve the effects of keeping the body comfortable, good ventilation function, and improved netting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

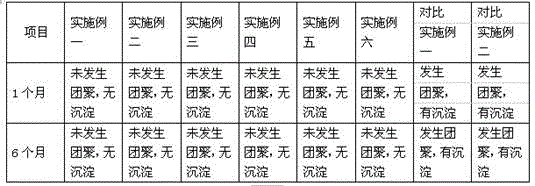

Embodiment 1

[0063] Mountain brown jute composite mattress preparation includes:

[0064] Preparation of mountain palm fiber:

[0065] ①Steaming: Cook the purchased mountain palm slices. The cooking method is to place the mountain palm slices in the cooking liquid and perform repeated pressurization and decompression operations in the pressure tank. The bath ratio is 4:1, and the cooking time is 50min; the cooking liquid is 1.5g / L of sodium carbonate, 6.7g / L of sodium silicate, 0.05g / L of dimethylsulfoxide, 0.6g / L of 1-butyl-3-methylimidazole Chlorine salt, 9g / L hydrogen peroxide and water composition; The pressurization should make the temperature in the pressure tank reach 110°C, and the decompression is to quickly release the pressure in the pressure tank to the atmosphere after pressurization and heating;

[0066] ②Separation: Put the boiled and dried palm palm slices on the conveyor belt and enter the rolling and splitting machine to automatically separate them into natural curly pal...

Embodiment 2

[0103] Mountain brown jute composite mattress preparation includes:

[0104] Preparation of mountain palm fiber:

[0105] ①Steaming: Cook the purchased mountain palm slices. The cooking method is to place the mountain palm slices in the cooking liquid and perform repeated pressurization and decompression operations in the pressure tank. The bath ratio is 3:1, and the cooking time is 40min; the cooking liquid is 1-butyl-3-methylimidazolium chloride salt of sodium carbonate of 1g / L, sodium silicate of 6g / L, dimethyl sulfoxide of 0.03g / L, 0.5g / L , 10g / L hydrogen peroxide and water; the pressurization should make the temperature in the pressure tank reach 100°C, and the decompression is to quickly release the pressure in the pressure tank to the atmosphere after pressurization and heating;

[0106] ②Separation: Put the boiled and dried palm palm slices on the conveyor belt and enter the rolling and splitting machine to automatically separate them into natural curly palm palm fibe...

Embodiment 3

[0136] Mountain brown jute composite mattress preparation includes:

[0137] Preparation of mountain palm fiber:

[0138] ①Steaming: Cook the purchased mountain palm slices. The cooking method is to place the mountain palm slices in the cooking liquid and perform repeated pressurization and decompression operations in the pressure tank. The bath ratio is 5:1, and the cooking time is 60min; the cooking liquid is 2g / L of sodium carbonate, 7g / L of sodium silicate, 0.07g / L of dimethylsulfoxide, 0.9g / L of 1-butyl-3-methylimidazolium chloride , 8g / L hydrogen peroxide and water; the pressurization should make the temperature in the pressure tank reach 120°C, and the decompression is to quickly release the pressure in the pressure tank to the atmosphere after pressurization and heating;

[0139] ②Separation: Put the boiled and dried palm palm slices on the conveyor belt and enter the rolling and splitting machine to automatically separate them into natural curly palm palm fibers, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com