Titanium dioxide photocatalyst coating and film and preparation method thereof

A technology of titanium dioxide and anatase titanium dioxide, which is applied in the field of photocatalyst materials and can solve problems such as inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The application also relates to the preparation method of the titanium dioxide photocatalyst, at least comprising the following steps:

[0051] (1) Mix anatase-type titanium dioxide powder, rare earth element oxide powder and triethyl borate in proportion, grind them, and grind them for 6-15 hours under the condition of 60-100°C to obtain a particle size of 10 nm or less. Nano powder;

[0052] (2) Disperse the prepared nano-powder in an organic solvent to form a sol, and the mass percentage of the nano-powder in the solution is 30-40%, that is, the titanium dioxide photocatalyst is obtained.

[0053] As an improvement of the preparation method of the present application, when the titanium dioxide photocatalyst is also doped with carbon elements, in step (2), the graphene oxide is first configured into a graphene oxide solution, and then the graphene oxide solution is added dropwise to the In the nano-powder, grind for 1-3 hours, then add an organic solvent to continue ...

Embodiment 1

[0065] A kind of titanium dioxide photocatalyst paint, is doped with rare earth element and boron element, and its preparation method is:

[0066] 1. The raw materials for the preparation of titanium dioxide photocatalyst coatings: anatase titanium dioxide powder, rare earth element oxide powder and triethyl borate are weighed in proportion and then mixed. The specific ratio is shown in Table 1; among them, the anatase The anatase phase content of the titanium dioxide powder is ≥90%; the anatase type titanium dioxide is selected as a powder with a D95 of about 5 μm, and the rare earth element oxide is selected as a powder with a D95 of about 5 μm; use a high-energy ball mill to grind at 60 ° C for 12 hours , to obtain nanopowder with particle size below 10nm;

[0067] 2. Disperse the prepared nano-powder in a mixed solvent of acrylic acid ethanol / cyclohexanone (volume ratio 70:30) in an ultrasonic disperser, and the frequency of ultrasonic dispersion is 30KHz; that is, the tit...

Embodiment 2

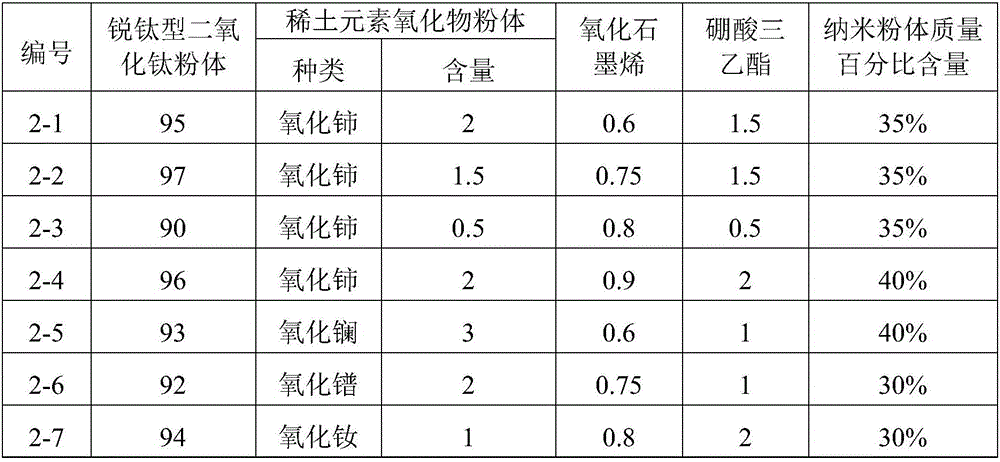

[0072] A titanium dioxide photocatalyst coating, doped with rare earth elements, boron elements and carbon elements, its preparation method is:

[0073] 1. The raw materials for the preparation of titanium dioxide photocatalyst coatings: anatase titanium dioxide powder, rare earth element oxide powder and triethyl borate are weighed in proportion and then mixed. Among them, the anatase phase content of the anatase titanium dioxide powder is ≥ 90%; the anatase titanium dioxide chooses the powder with D95 of about 5 μm, and the rare earth element oxide chooses the powder with D95 of about 5 μm; use a high-energy ball mill to grind at 60 ° C for 12 hours to obtain nanometer particles with a particle size of less than 10 nm Powder;

[0074] 2. Weigh the graphene oxide in proportion, configure it into an ethanol solution of graphene oxide, then add the graphene oxide solution dropwise into the nanopowder, and grind for 2 hours with a high-energy ball mill, the graphene oxide in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com