Preparation method of polyurethane modified epoxy resin and grouting material based on resin

A technology of epoxy resin grouting and polyurethane modification, which is applied in the field of building materials, can solve the problems of slow curing, poor toughness, and low wet bonding strength, and achieve the effects of low curing strength at low temperature, reduced force, and high resin viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

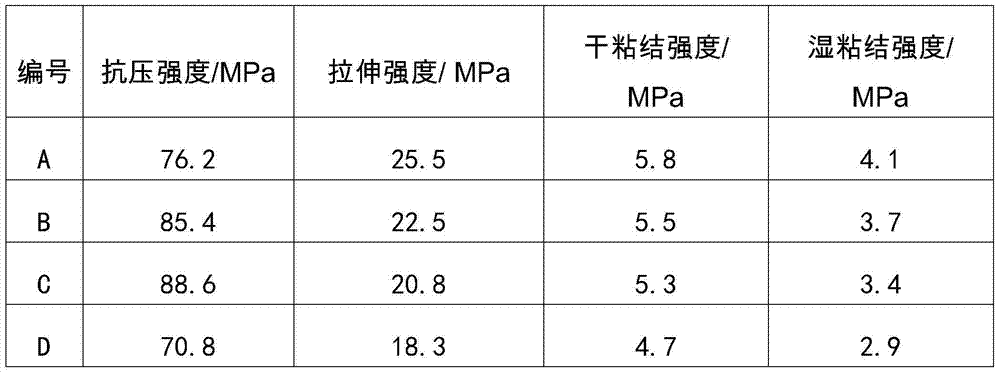

Examples

Embodiment 1

[0027] A kind of polyurethane modified epoxy resin is provided in the present embodiment, and the raw material composition of described polyurethane modified epoxy resin is as follows:

[0028] Epoxy resin E51, 60 parts by weight of epoxy value 0.6mol / 100g; Toluene diisocyanate, 18 parts by weight; Catalyst dibutyltin dilaurate, 0.05 parts by weight; Diluent benzyl glycidyl ether, 50 parts by weight; Plasticizer dioctyl phthalate, 10 parts by weight; Inorganic toughening agent talcum powder, 20 parts by weight.

[0029] The preparation method of described polyurethane modified epoxy resin is:

[0030] (a) under vacuum conditions, 50wt% of the epoxy resin, that is, 30 parts by weight of the epoxy resin, is first heated to 100°C, stirred for 2h, and then cooled to 50°C;

[0031] (b) adding the above-mentioned isocyanate and catalyst in the epoxy resin described in step (a), and reacting for 3 hours in an inert gas at a temperature of 80° C. to obtain a polyurethane grafted epox...

Embodiment 2

[0038] A kind of polyurethane modified epoxy resin is provided in the present embodiment, and the raw material composition of described polyurethane modified epoxy resin is as follows:

[0039] Epoxy resin E44 with an epoxy value of 0.4mol / 100g, 80 parts by weight; Hexamethylene diisocyanate, 10 parts by weight; Catalyst triethylamine, 0.5 parts by weight; Diluent ethylene glycol glycidyl ether, 10 parts by weight ; Plasticizer diethyl phthalate, 20 parts by weight; Inorganic toughening agent fumed silica, 5 parts by weight.

[0040] The preparation method of described polyurethane modified epoxy resin is:

[0041] (a) under vacuum conditions, 40wt% of the epoxy resin, that is, 32 parts by weight of the epoxy resin, is first heated to 110°C, stirred for 1h, and then cooled to 60°C;

[0042] (b) adding isocyanate and a catalyst to the epoxy resin described in step (a), and reacting for 1 h in an inert gas at a temperature of 90° C. to obtain a polyurethane grafted epoxy resin;...

Embodiment 3

[0049] A kind of polyurethane modified epoxy resin is provided in the present embodiment, and the raw material composition of described polyurethane modified epoxy resin is as follows:

[0050] Epoxy resin E44 with an epoxy value of 0.45mol / 100g, 70 parts by weight; Dicyclohexylmethane diisocyanate, 25 parts by weight; Catalyst stannous octoate, 0.2 parts by weight; Thinner o-cresol glycidyl ether, 30 parts by weight ; Plasticizer epoxy dioctyl tetrahydrophthalate, 15 parts by weight; Inorganic toughening agent fumed silica, 5 parts by weight.

[0051] The preparation method of described polyurethane modified epoxy resin is:

[0052] (a) under vacuum conditions, 60wt% of the epoxy resin, that is, 42 parts by weight of the epoxy resin, is first heated to 110°C, stirred for 1h, and then cooled to 60°C;

[0053] (b) adding isocyanate and a catalyst to the epoxy resin described in step (a), and reacting for 1 h in an inert gas at a temperature of 90° C. to obtain a polyurethane g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com