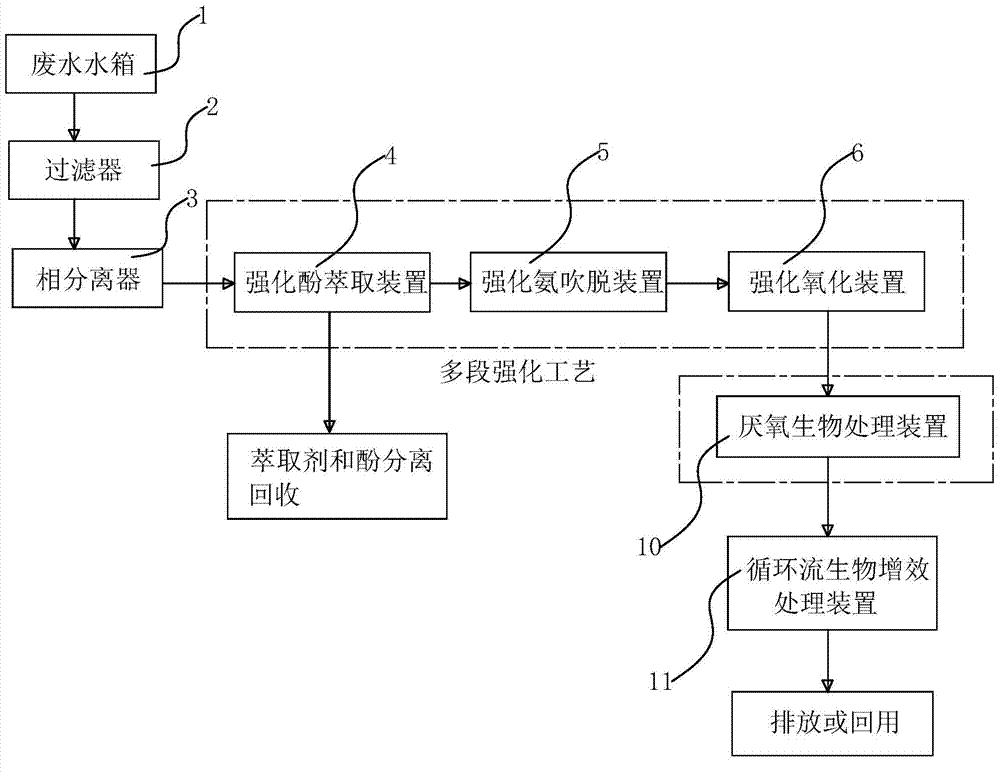

Device and method for treating chemical wastewater

A technology for treating device and chemical wastewater, applied in the field of energy saving and environmental protection, can solve problems such as low treatment cost, and achieve the effects of improving biodegradability, reducing load, and realizing resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

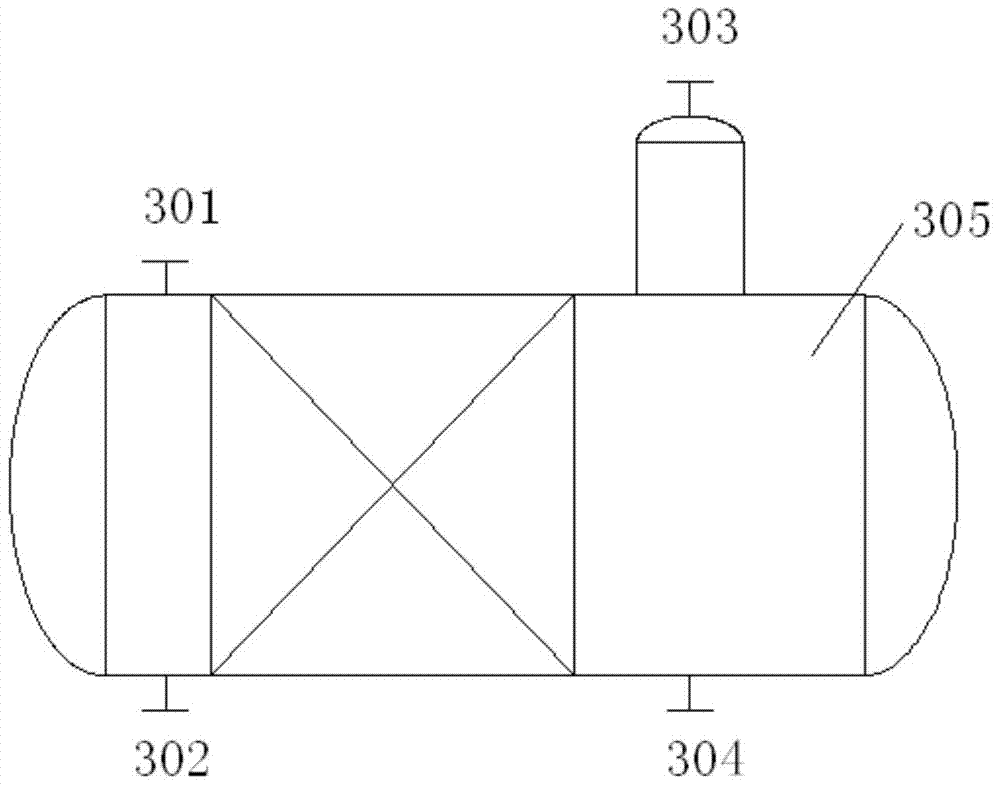

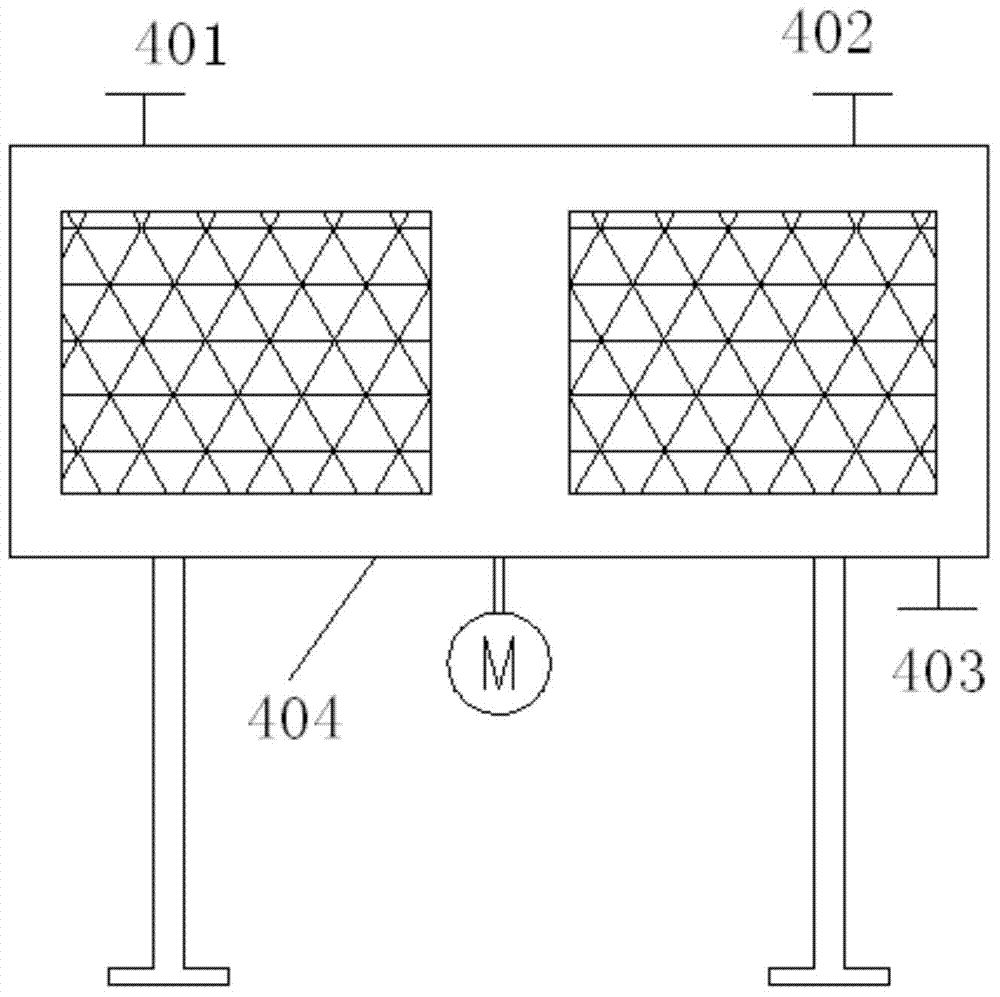

Embodiment 1

[0051] Embodiment 1: The treated waste water is coal medium-temperature coking waste water, and the flow rate is 10m3 / h, COD Cr (COD stands for chemical oxygen demand, which refers to the amount of oxidant consumed to oxidize reducing substances in 1L of water samples under certain conditions, expressed as the mass concentration of oxygen (in mg / L) to measure chemical oxygen demand The standard method is the potassium dichromate method. The chemical oxygen demand measured by the potassium dichromate method is called CODcr.) The value is 50000mg / L, the oil content is 2500mg / L, the total phenol content is 16000mg / L, and the ammonia nitrogen content is 4000mg / L, SS (suspended solids) about 880mg / L. After being treated by a phase separator, the non-emulsified oil can be basically removed and recovered, and the COD is reduced to 39800mg / L. After two-stage enhanced extraction process and two-stage steam enhanced blow-off process, COD decreased to 7164mg / L, total phenol decreased t...

Embodiment 2

[0052] Embodiment 2: The treated waste water is coal tar catalytic waste water, and the flow rate is 6m 3 / h, COD Cr The value is 60000mg / L, the oil content is 13000mg / L, the total phenol content is 25000mg / L, the ammonia nitrogen content is 15000mg / L, and the sulfide content is 21000mg / L. After being treated by a phase separator, the non-emulsified oil can be basically removed and recovered, and the COD is reduced to 51120mg / L. After the three-stage enhanced extraction process and the first-stage steam enhanced stripping process, the COD decreased to 3500mg / L, the oil content decreased to 48mg / L, the total phenol decreased to 700mg / L, the ammonia nitrogen decreased to 500mg / L, and the sulfide decreased to 20mg / L. Because the COD is higher than 2000mg / L at this time, the enhanced oxidation process cannot be used, but the anaerobic process must be used. After being treated by anaerobic expanded granular sludge bed (EGSB) and circulating flow biosynergistic reactor, the water...

Embodiment 3

[0053] Embodiment 3: The treated waste water is coal gas waste water, and the flow rate is 15m 3 / h, COD Cr The value is 25000mg / L, the oil content is 1000mg / L, the total phenol content is 7500mg / L, and the ammonia nitrogen content is 8000mg / L. After being treated by a phase separator, the non-emulsified oil can be basically removed and recovered, and the COD can be reduced to 20500mg / L. After the secondary enhanced extraction process and the secondary steam enhanced stripping process, COD decreased to 1800mg / L, oil content decreased to 35mg / L, total phenol decreased to 650mg / L, and ammonia nitrogen decreased to 80mg / L. Because the COD is lower than 2000mg / L at this time, the enhanced oxidation process can be adopted. After enhanced oxidation by ultraviolet catalyzed hydrogen peroxide, the COD will be reduced to 1320mg / L, the oil content will be reduced to 28mg / L, the total phenols will be reduced to 85mg / L, and the ammonia nitrogen content will be basically unchanged, BOD ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com