Method for preparing APT (Ammonium Paratungstate) from tungsten mineral raw material with zero waste water discharge

A technology of mineral raw materials and raw materials, applied in the field of tungsten smelting, can solve the problems of non-circulation, difficult continuous production, high production cost, etc., and achieve the effects of reducing energy consumption and cost, easy industrial application, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

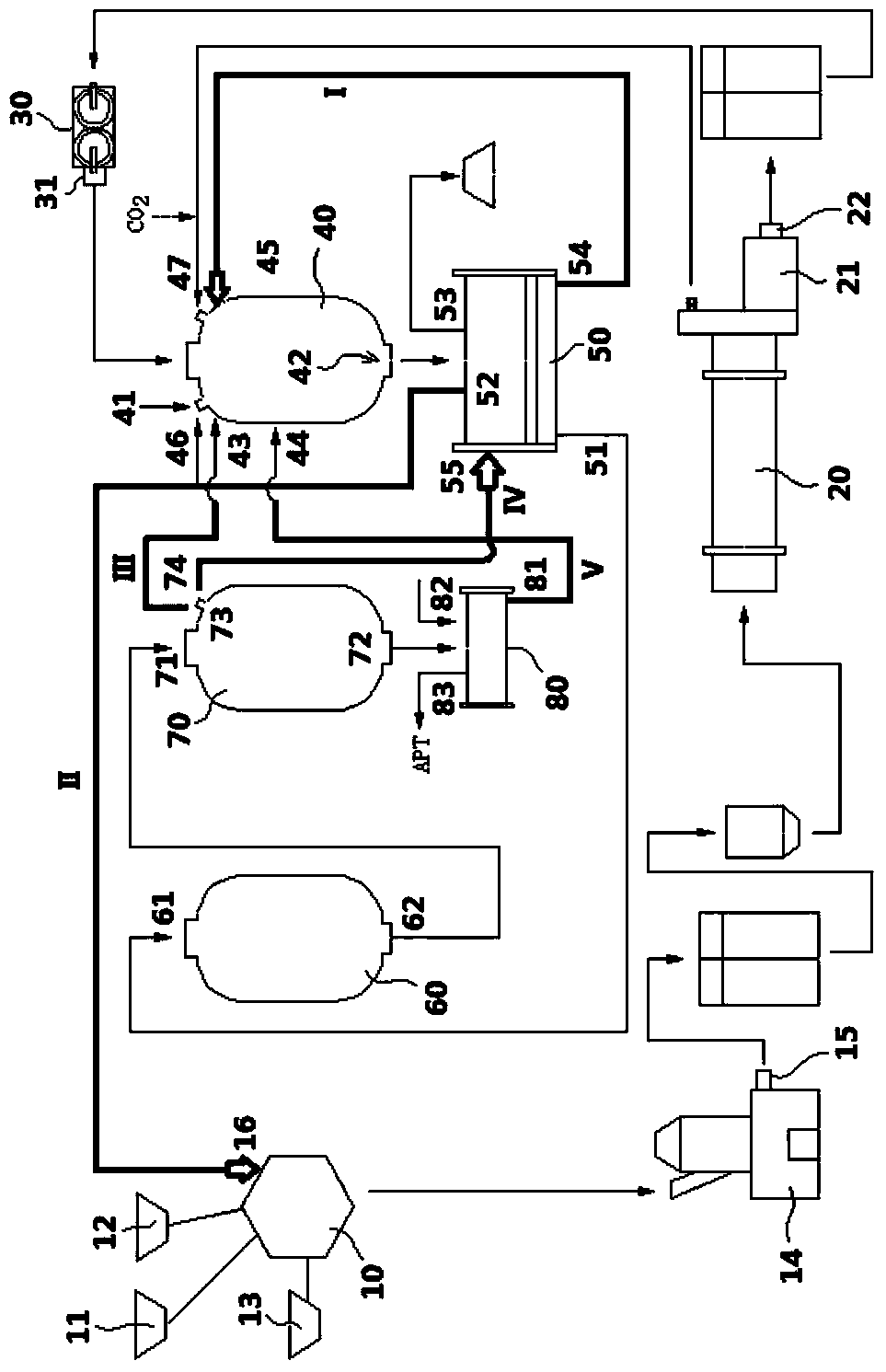

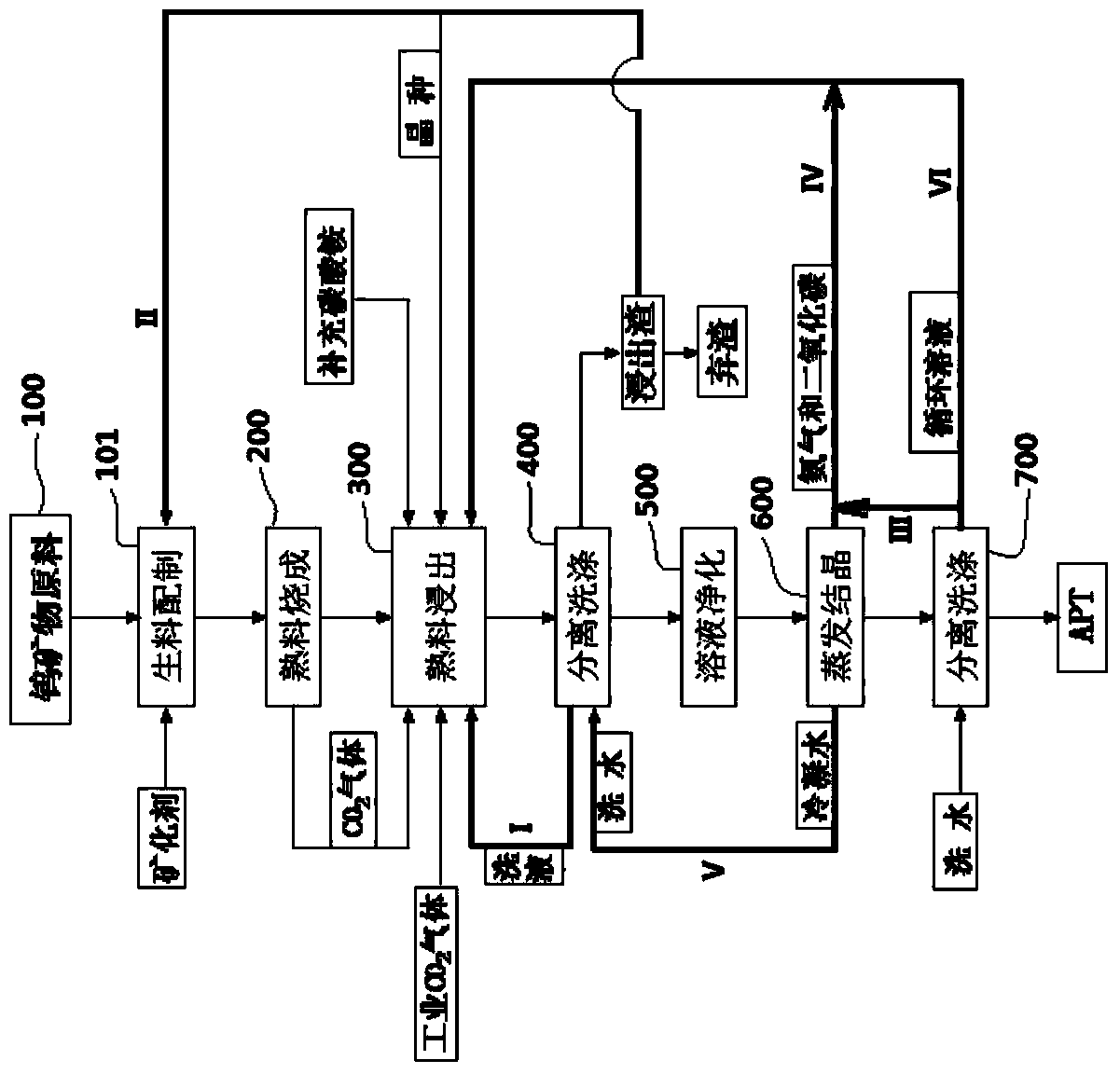

Method used

Image

Examples

Embodiment 1

[0103] Embodiment 1: certain scheelite (WO 3 The mass percent composition is 49.53%, and the Fe mass percent composition is 0.43%) by generating Ca 3 WO 6 1.1 times the theoretical amount, mixed with clinker leaching slag (the main component is CaCO 3 ) and mineralizer calcium fluoride are ground and mixed to obtain the raw meal, the addition of calcium fluoride is 5.2% (mass percentage) of the dry tungsten mineral raw material amount, and the particle size of the raw meal is ≤40 μm. Then, in the roasting furnace In the air atmosphere, the clinker was obtained by roasting at 800°C for 2.0h. After the clinker is cooled to room temperature, it is ground with a vibrating mill, and the clinker particle size is ≤45 μm. Weigh 5.0g of finely ground clinker and add it to the reaction kettle with ventilation and mechanical stirring device, and add 50g-(NH 4 ) 2 CO 3 / 100g-H 2 O ammonium carbonate solution 50mL and sealed, and then into CO 2 gas, control the absolute pressure of...

Embodiment 2

[0104] Embodiment 2: a certain black and white tungsten mixed ore (WO 3 The mass percent composition is 63.75%, and the Fe mass percent composition is 5.90%) by generating Ca 3 WO 6 and Ca 2 FeWO 6 1.5 times the theoretical amount, mixed with clinker leaching slag for grinding and mixing to obtain raw meal, raw meal particle size ≤ 45μm, and then roasted at 950°C for 3.0h in a shaft furnace under a weak reducing atmosphere to obtain cooked material. After the clinker is cooled to room temperature, it is ground with a ball mill, and the particle size of the clinker is ≤45 μm. Take by weighing 20.0g clinker and join in the reaction kettle of band ventilation and mechanical stirring device, add 35g-(NH 4 ) 2 CO 3 / 100g-H 2 O ammonium carbonate solution 100mL and sealed, and then into CO 2 Gas, control the absolute pressure of the reaction system to 2atm, and react at 70°C for 4h. After the reaction, the leached pulp is vacuum filtered, and the filter cake is washed thre...

Embodiment 3

[0105] Embodiment 3: certain wolframite (WO 3 The mass percent composition is 62.40%, the Fe mass percent composition is 14.08%, and the Mn mass percent composition is 2.25%) by generating Ca 3 WO 6 and Ca 2 FeWO 6 and Ca 2 MnO 6 1.13 times the theoretical amount, mixed with clinker leaching slag and calcium fluoride for grinding and mixing to obtain raw meal, the amount of calcium fluoride added is 7% (mass percentage) of the dry tungsten mineral raw material amount, the raw meal particle size ≤40μm, then, in a tube-type roasting furnace, under a neutral atmosphere, roast at 800°C for 6.0h to obtain clinker, after the clinker is cooled to room temperature, grind it with a rod mill, the clinker particle size is ≤45μm; leaching equipment Choose a ball mill leaching device with a built-in saturated ammonium carbonate solution, and add ammonium bicarbonate according to 1.0 times the theoretical amount; put the clinker into the leaching equipment, and react at 80°C for 4 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com