Preparation method of powder injection molded feeding material

A technology of powder injection molding and powder, which is applied in the field of powder injection molding feed preparation, can solve the problems of increasing labor intensity of workers, low equipment utilization rate, long process time, etc., and achieves short preparation process cycle, high equipment utilization rate, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of powder injection molding feed, comprising the following steps:

[0020] S1. Grinding the organic high molecular polymer used as the binder component to the same particle size level as the inorganic material powder to be mixed. For example, ultra-low temperature pulverization, such as pulverization at -50°C or below, can be used.

[0021] S2. Heating the inorganic material powder to a predetermined temperature, the predetermined temperature being a temperature capable of melting the binder;

[0022] S3. Add the binder processed in step S1 to the powder raw material that has reached the predetermined temperature and mix, so that the powder raw material and the binder are pre-bonded into agglomerates, wherein the binder includes the powder treated in step S1. of organic polymers;

[0023] S4. Sending the material processed in step S3 into an extruder, plasticizing, extruding, and granulating to obtain a powder injection mold...

Embodiment 1

[0037] This embodiment provides a method for preparing feedstock for stainless steel powder injection molding, which belongs to the field of metal powder injection molding, and the specific process is as follows:

[0038] 1) Provide stainless steel powder to be mixed, the stainless steel powder used is obtained by, for example, hydrometallurgical chemical engineering method, and the particle size is roughly 0.5-3 μm;

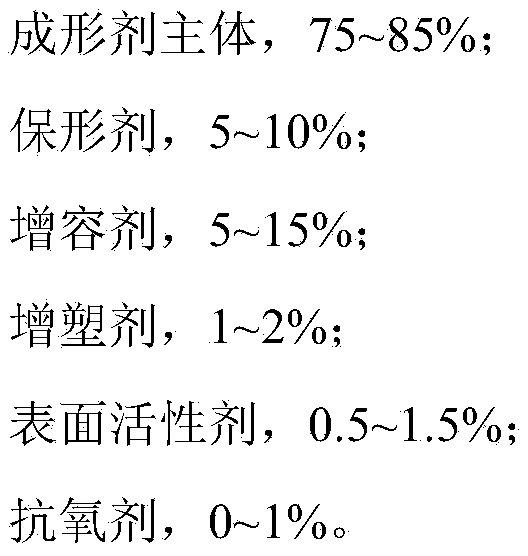

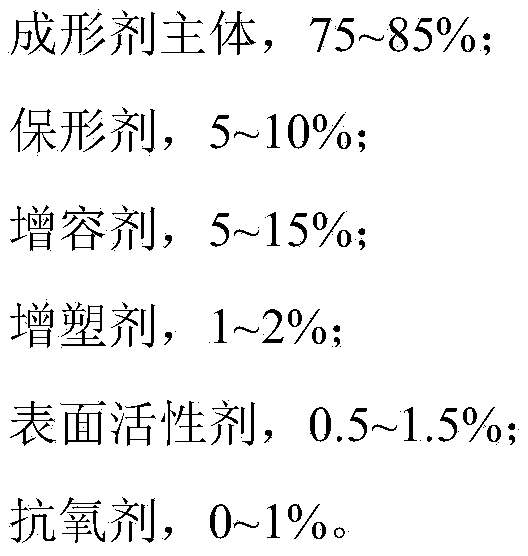

[0039] 2) Provide raw materials for binders: polyoxymethylene copolymer, modified K resin, fully refined paraffin wax, polypropylene wax, polyacrylamide, antioxidant, and the copolymerized polyoxymethylene and modified K resin are subjected to ultra-low temperature below -50°C Deep crushing, crushing to a particle size of less than 80 μm, which is at the same particle size level as stainless steel powder;

[0040] 3) Take 10% of fully refined paraffin wax, 1.5% of polypropylene wax, 1% of polyacrylamide, 0.5% of antioxidant, and 80% of polyoxymethylene and 7.5% ...

Embodiment 2

[0045] This embodiment provides a method for preparing cermet powder injection molding feed, which belongs to the field of metal injection molding, wherein the cermet can be titanium carbonitride-based cermet, for example: TiCN-(5~15)% (W-Ta / Nb-V / Cr)C-(10~30)%Co / Ni, the specific process is as follows:

[0046] 1) Provide cermet powder with a particle size of 0.5-3 μm to be mixed;

[0047] 2) Provide raw materials for binders: polyoxymethylene copolymer, modified K resin, fully refined paraffin wax, polypropylene wax, polyacrylamide, antioxidant, and the values of polyoxymethylene copolymer and modified K are respectively subjected to ultra-low temperature below -50°C Deep crushing, crushed to less than 80μm, at the same particle size level as cermet powder;

[0048] 3) Take 10% of fully refined paraffin wax, 1% of polypropylene wax, 1% of polyacrylamide, 0.5% of antioxidant, and 77.5% of polyoxymethylene processed through process 2) and 10% of modified K resin by volume pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com