Preparation method of flaky nanometer zinc oxide powder

A nano-zinc oxide powder and flake technology is applied in the field of preparation of flake nano-zinc oxide powder, can solve the problems of high toxicity, high cost, unfavorable production and environment, and achieves simplified production process, reduced equipment investment, reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

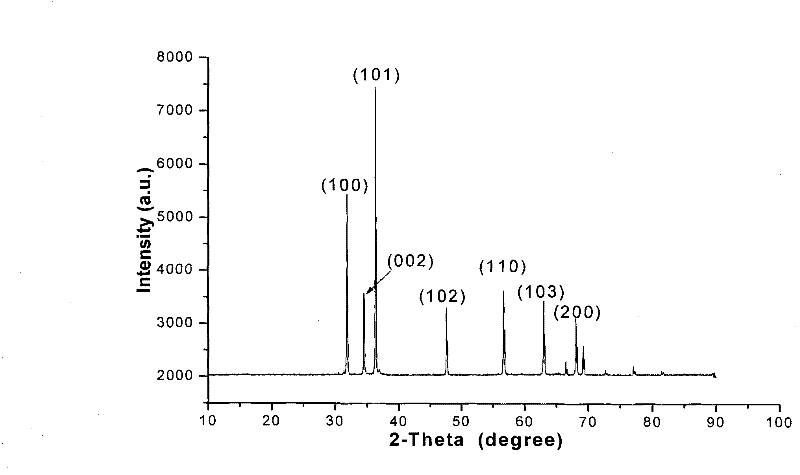

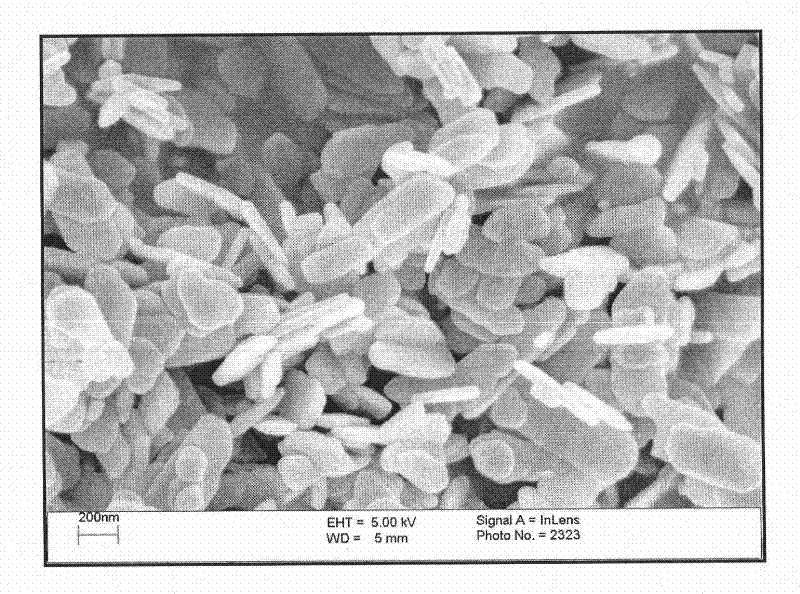

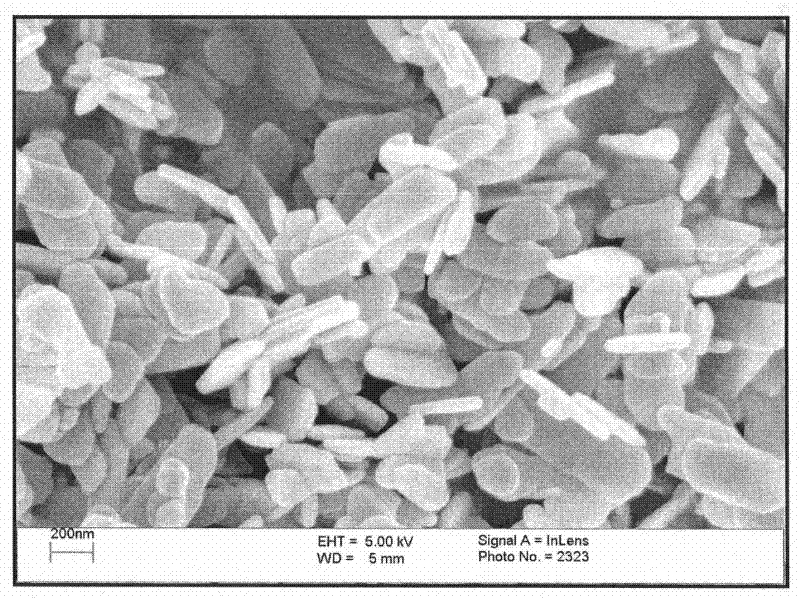

[0024] A certain amount of zinc chloride is dissolved in a certain volume of deionized water to prepare a solution with a molar concentration of 0.1 mol / L, and 0.2 wt% of solute weight of PEG 8000 is added. Use an automatic titrator to add 25% ammonia solution dropwise to pH = 11, transfer the solution into a 100 mL Teflon-lined stainless steel reaction kettle so that the filling degree of the reaction kettle is 70%, and conduct hydrothermal treatment at 200 degrees Celsius 24 hours. The product is washed about 5 times with deionized water to remove acid radical ions and impurity ions, and dried at 100 degrees Celsius for about 12 hours to obtain a single dispersed white flaky zinc dioxide powder. The particle size is around 80 nm.

Embodiment 2

[0026] A certain amount of zinc chloride is dissolved in a certain volume of deionized water to prepare a solution with a molar concentration of 0.5 mol / L, and 0.2 wt% of solute weight of PEG 8000 is added. Use an automatic titrator to add 25% ammonia solution dropwise to pH = 11, transfer the solution into a 100 mL Teflon-lined stainless steel reaction kettle so that the filling degree of the reaction kettle is 70%, and conduct hydrothermal treatment at 200 degrees Celsius 24 hours. The product is washed about 5 times with deionized water to remove acid radical ions and impurity ions, and dried at 100 degrees Celsius for about 12 hours to obtain a single dispersed white flaky zinc dioxide powder. The particle size is 60-70 nanometers.

Embodiment 3

[0028] A certain amount of zinc chloride is dissolved in a certain volume of deionized water to prepare a solution with a molar concentration of 1.0 mol / L, and 0.2 wt% of solute weight of PEG 8000 is added. Use an automatic titrator to add 25% ammonia solution dropwise to pH = 11, transfer the solution into a 100 mL Teflon-lined stainless steel reaction kettle so that the filling degree of the reaction kettle is 70%, and conduct hydrothermal treatment at 200 degrees Celsius 24 hours. The product is washed about 5 times with deionized water to remove acid radical ions and impurity ions, and dried at 100 degrees Celsius for about 12 hours to obtain a single dispersed white flaky zinc dioxide powder. The particle size is around 40 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com