Device and method for use of impeller of laser 3D (three dimensional) -printing pump

A printing pump, 3D technology, applied in the direction of turbines, other manufacturing equipment/tools, engine components, etc., can solve the problems of different mechanical performance requirements of pump impellers, achieve resource saving, excellent surface performance, and reduce printing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific examples.

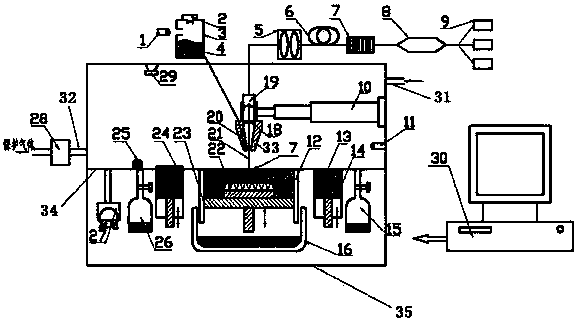

[0022] A device for laser 3D printing pump impellers, such as figure 1 As shown, it includes a laser head 19, a powder feeder 3, a powder spray head 33, a three-degree-of-freedom manipulator 10, a worktable 34, a vacuum pump 27 and a closed cavity 35, the laser head 19 is installed on the powder spray head 33, and the laser head 19 is sequentially connected with focusing collimator 5 , double-clad ytterbium-doped ion fiber 6 , fiber grating 7 , coupler 8 and multimode laser diode pumping source 9 . The powder feeder 3 is connected with the powder inlet hole 20 on the powder nozzle, the powder feeder 3 is provided with a powder feeding port 2, and the powder feeder 3 is connected with the argon gas source 1, which is used for the powder feeder 3 provides power, the powder nozzle 33 is controlled by the three-degree-of-freedom manipulator 10, and can move up and down,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com