A kind of preparation method of baking varnish type waterborne polyurethane/amino resin composite emulsion

A water-based polyurethane and amino resin technology, applied in the field of water-based polyurethane, can solve the problems of difficult adhesion of coatings, low content of water-based polyurethane, and emission of volatile organic compounds, and achieve reduced emissions, high cross-linking degree, high hydroxyl functionality and hydroxyl value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

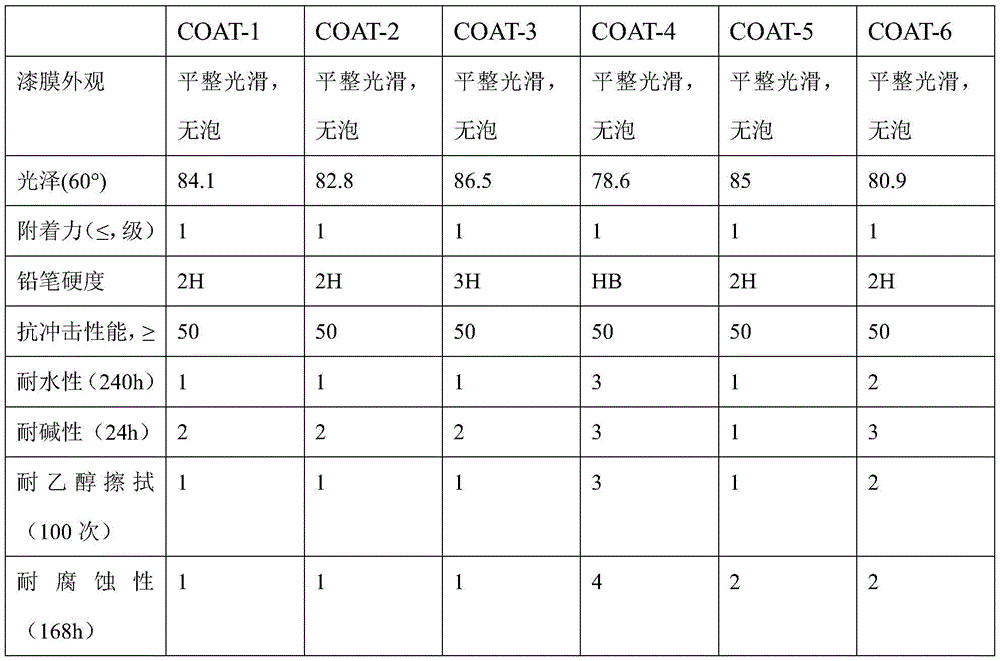

Embodiment 1

[0022] Synthesize first with polypropylene carbonate diol as one of the components of the polyhydroxyl-terminated water-based polyurethane prepolymer emulsion: 120 grams of number-average molecular weight is 2000 of PPC and 30 grams of number-average molecular weight of 2000 PPG at 110 After dehydration at -120°C for 1 hour, cool to 50°C, add 100 grams of IPDI, react at 90°C for 3 hours, add 18 grams of DMPA, 7 grams of BDO, 3 grams of TMP, 250 grams of acetone and 0.4 grams of DBTDL, After 8 hours of reaction, a polyurethane prepolymer solution was obtained; 25.83 grams of diethanolamine was added, and the reaction was carried out at 60°C for 3 hours; After 10 minutes, add 696 grams of water, stir for 10 minutes, transfer the reaction product to a rotary evaporator, remove acetone at 40-50°C under vacuum conditions, and obtain polyhydroxyl-terminated water-based polyurethane prepolymer emulsion I (PUD -1), the hydroxyl value of its solid component is 88.3mgKOH / g, and the acid...

Embodiment 2

[0030] 95 grams of PPC with a number average molecular weight of 2000 and 55 grams of PPG with a number average molecular weight of 2000 were dehydrated at 110-120°C for 1 hour and then cooled to 50°C. Added 100 grams of IPDI and reacted at 90°C for 3 hours, followed by adding 18 gram DMPA, 7 gram BDO, 3 gram TMP, 250 gram acetone and 0.4 gram DBTDL, obtain polyurethane prepolymer solution after 8 hours of reaction at 60 ℃; Add 25.83 gram diethanolamine again, react 3 hours at 60 ℃; Add 14 grams of TEA under the condition of rotating speed shearing per minute and 0-40 °C, and react for 2 minutes, add 696 grams of water, stir for 10 minutes, transfer the reaction product to a rotary evaporator, and heat it at 40-50 °C, Acetone was removed under vacuum conditions to obtain polyhydroxyl-terminated aqueous polyurethane prepolymer emulsion II (PUD-2), the hydroxyl value of its solid component was 88.3 mgKOH / g, and the acid value was 24.8 mgKOH / g;

[0031] Then 500 grams of PUD-2 pr...

Embodiment 3

[0033] 120 grams of PPC with a number average molecular weight of 2000 and 30 grams of PPG with a number average molecular weight of 2000 were dehydrated at 110-120 °C for 1 hour and then cooled to 50 °C, 78.4 grams of TDI were added, and after reacting at 80 °C for 3 hours, 18 gram DMPA, 7 gram BDO, 3 gram TMP, 250 gram acetone and 0.4 gram DBTDL, obtain polyurethane prepolymer solution after 8 hours of reaction at 60 ℃; Add 25.83 gram diethanolamine again, react 3 hours at 60 ℃; Add 14 grams of TEA under the condition of rotating speed shearing per minute and 0-40 °C, and react for 2 minutes, add 696 grams of water, stir for 10 minutes, transfer the reaction product to a rotary evaporator, and heat it at 40-50 °C, Acetone was removed under vacuum conditions to obtain polyhydroxyl-terminated aqueous polyurethane prepolymer emulsion III (PUD-3), the hydroxyl value of its solid component was 94.9 mgKOH / g, and the acid value was 26.7 mgKOH / g;

[0034] Then 500 grams of PUD-3 pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com