A kind of solvent-resistant environment-friendly water-based coating and preparation method thereof

A technology of water-based paint and solvent resistance, which is applied in the field of paint to achieve the effects of convenient industrial production, simple preparation process and high solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

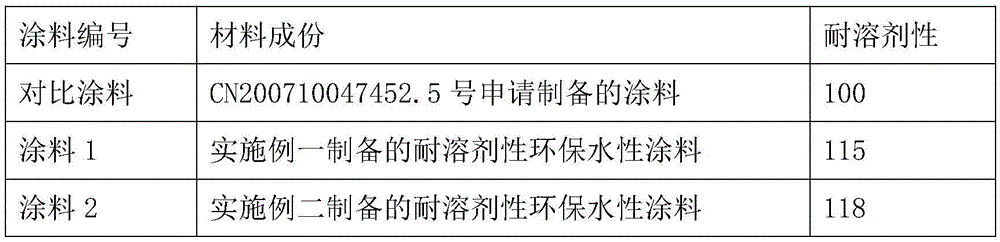

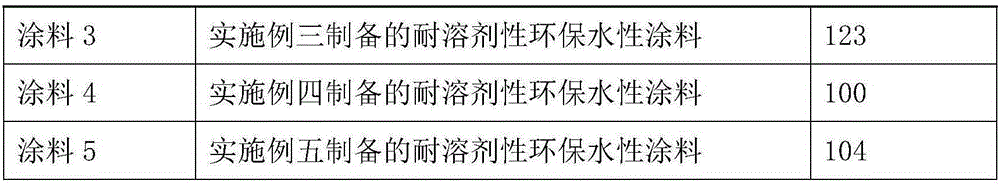

Examples

Embodiment 1

[0031] The preparation method of solvent-resistant environmental protection water-based paint of the present invention, the method comprises the following steps:

[0032] 1) Acetal resin composite oxide preparation:

[0033] The ingredients are formulated according to the following weight percentages: 5% calcium oxide, 15% waste glass, 16% sodium oxide, 0.6% cerium oxide, and the rest is silicon oxide; the particle size of each material is 1-4mm;

[0034] Mix the materials evenly, then put them into the crucible in the heating furnace and heat to 1430 degrees, take out the crucible after 12 minutes of heat preservation, pour the molten inorganic materials into a steel mold and cool to room temperature; then crush and grind the obtained composite oxide to 10-20 microns;

[0035] The acetal resin is heated at 195 degrees to obtain a molten substance, then the above-mentioned composite oxide is added to the molten acetal resin and stirred evenly, and naturally cooled to room tem...

Embodiment 2

[0042] The preparation method of solvent-resistant environmental protection water-based paint of the present invention, the method comprises the following steps:

[0043] 1) Acetal resin composite oxide preparation:

[0044] The ingredients are formulated according to the following weight percentages: 8% calcium oxide, 18% waste glass, 18% sodium oxide, 0.8% cerium oxide, and the rest is silicon oxide; the particle size of each material is 1-4mm;

[0045] Then mix the materials evenly, then put them into the crucible in the heating furnace and heat to 1450 degrees, take out the crucible after keeping it warm for 15 minutes, pour the molten inorganic material into a steel mold and cool it to room temperature; then crush and grind the obtained composite oxide to 10-20 microns;

[0046] Heat the acetal resin at 200 degrees to obtain a molten substance, then add the above-mentioned composite oxide into the molten acetal resin and stir evenly, and naturally cool to room temperatur...

Embodiment 3

[0053] In the preparation process of the solvent-resistant and environment-friendly water-based coating of the present invention, the ingredients are formulated according to the following weight percentages, and the other conditions and preparation process are the same as in Example 1.

[0054] Synthetic resin 45%, epoxy resin 7%, thickener montmorillonite 4%, dispersant polyethylene glycol 4%, silicone emulsion 710%, titanium dioxide powder 8%, acetal resin composite oxide 12%, sulfuric acid Barium 0.3%, the rest is water. The weight ratio of the acetal resin and the composite oxide in the acetal resin composite oxide is 2:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com