Production method of ammonium phosphate containing trace elements

A technology of trace elements and production methods, applied in the field of compound fertilizers, can solve the problems of affecting soil properties, poor solubility, and poor appearance of product particles, and achieve the effects of uniform material distribution, high data utilization, and good solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

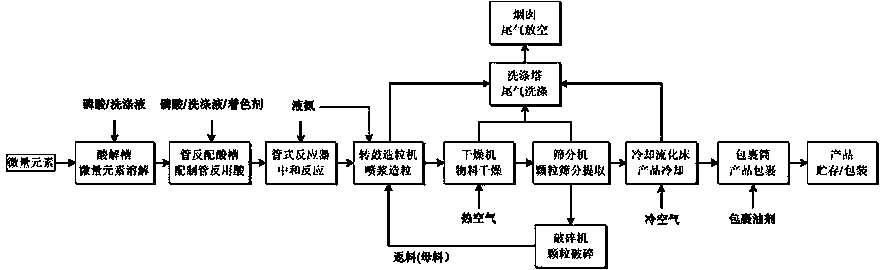

Image

Examples

Embodiment Construction

[0015] The trace elements boron (P), zinc (Zn), copper (Cu), sulfur (S), selenium (Se), iron (Fe), manganese (Mn), molybdenum (Mo), Sodium (Na) oxide or salt raw materials, including borax pentahydrate (Na 2 B 4 o 7 ·5H 2 O), borax decahydrate (Na 2 B 4 o 7 10H 2 O), zinc oxide (ZnO), zinc sulfate (ZnSO4), zinc phosphate (Zn 3 (PO 4 ) 2 ) copper sulfate (CuSO 4 ·5H 2 O), copper phosphate (Cu 3 (PO 4 ) 2 ), sodium phosphate (Na3PO4), sodium selenite (Na 2 SeO 3 ), sodium selenate (Na 2 SeO 4 ), molybdenum trioxide (MoO 3 ), selenium oxide (SeO), iron sulfate (FeSO 4 ), iron phosphate (FePO 4 ), iron oxide (Fe 2 o 3 ), manganese sulfate (MnSO 4 ), manganese oxide (MnO 2 ), sodium sulfate (NaSO 4 ), sodium iodide (NaI), sodium iodate (NaIO 3 ) of one or more oxides or salts, according to the product specifications, quantitatively and evenly added to the acid hydrolysis tank for trace elements, and concentrated phosphoric acid and washing liquid were adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com