Adhesive sheet for display

A bonding sheet and display technology, applied in the direction of film/sheet adhesives, adhesives, adhesive types, etc., can solve problems such as poor durability and physical property changes, and achieve excellent physical properties and excellent durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] 1. Preparation of base film and lamination of release film

[0137] As the first acrylate main resin, polybutyl methacrylate with a weight average molecular weight of 600000g / mol was used. With respect to 100 parts by weight of the above-mentioned first acrylate main resin, by mixing 0.225 parts by weight of N,N,N,N'-tetraglycidyl-m-xylylenediamine, 4.25 parts by weight of a compound represented by the following Chemical Formula 1 as a first antistatic agent, and 39 parts by weight of methyl ethyl as a solvent Ketones were used to prepare the first binder composition.

[0138] chemical formula 1

[0139]

[0140] The above-mentioned first antistatic agent has a T of about 341°C d value, a melting point of about -75°C and a viscosity of 635cPs.

[0141] Using a PET sheet with a thickness of 75 μm as the base material, poly-3,4-ethylenedioxythiophene / polystyrene sulfonate sodium (PEDOT / PSS) is film-coated on the lower surface for antistatic treatment, and the upper ...

Embodiment 2~ Embodiment 5

[0147] Example 2 to Example 5 and Comparative Example 1

[0148] Preparation was carried out in the same manner as in Example 1, however, as shown in Table 1 below, the adhesive sheet for display shown in Table 1 was prepared by changing the first adhesive composition, the composition of the substrate, etc. .

[0149] The antistatic agents used in Comparative Example 1 are as follows.

[0150] chemical formula 2

[0151]

[0152] Table 1

[0153]

experiment example

[0155] 1. Determination of physical properties at room temperature (23°C)

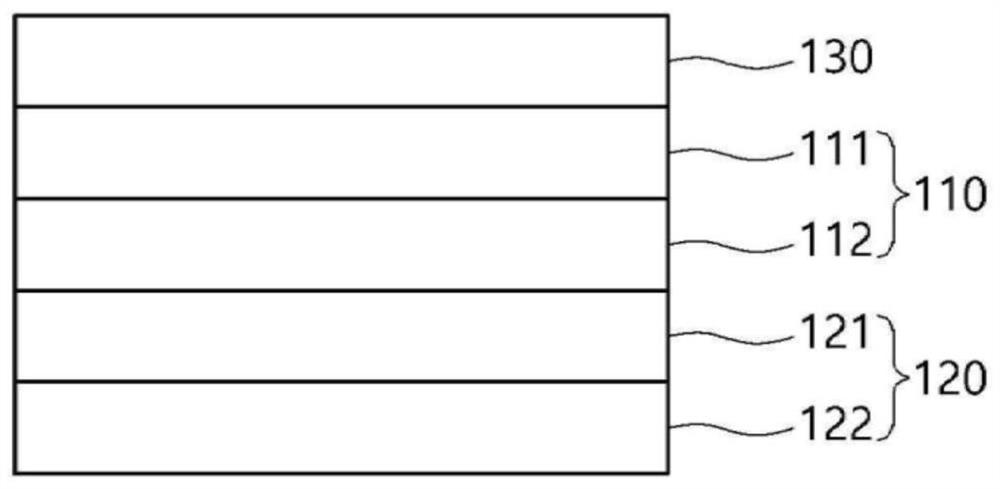

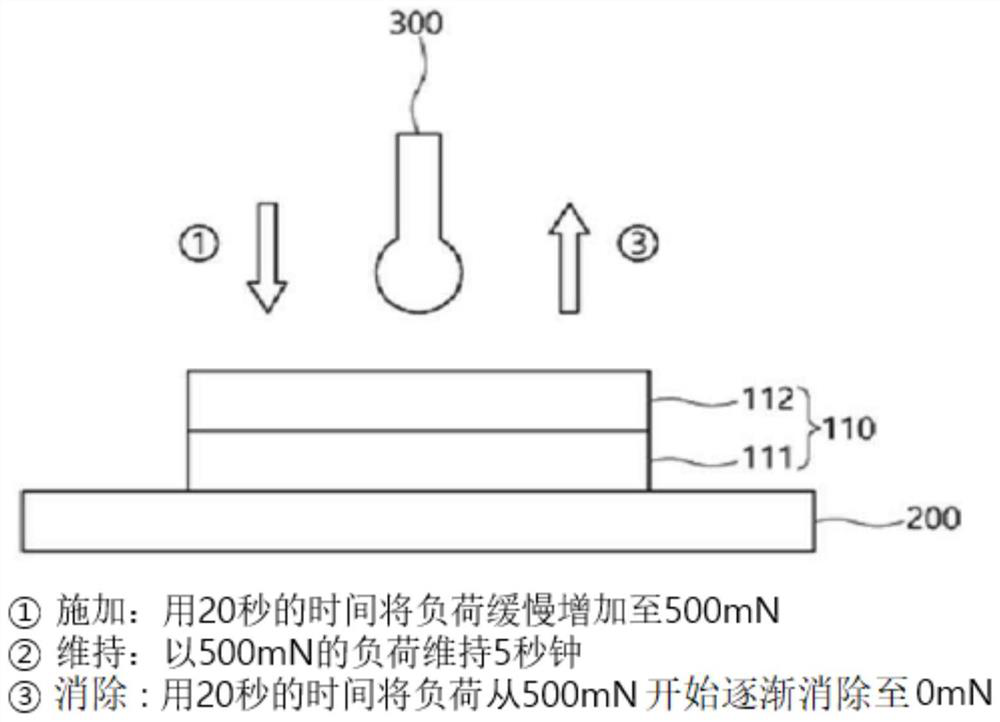

[0156] Such as figure 2 As shown, in the adhesive sheets for displays prepared by Examples and Comparative Examples, the release film was removed and the base adhesive layer was attached to the glass substrate, followed by removal of the carrier film.

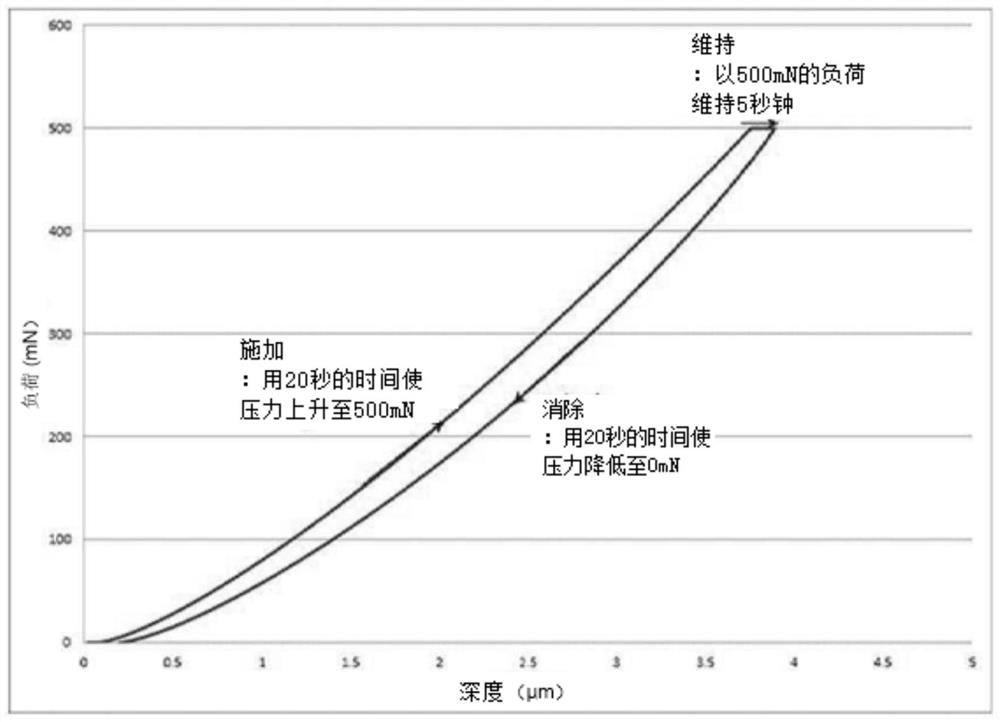

[0157] The elastic modulus, elastic recovery rate and plastic hardness were measured by pressing the base film attached to the glass substrate with a ball indenter with a diameter of 2 mm. The results are shown in Table 4. The detailed measurement method is as figure 2 As shown, use a ball indenter with a diameter of 2mm to increase the load to 500mN in 20 seconds and maintain the load of 500mN for 5 seconds. After 5 seconds, gradually reduce the load to 0mN in 20 seconds to form the load deformation. rate curve, and thus calculate the above physical properties (EIT RT , nIT RT 、HIT RT ).

[0158] 2. Determination of physical properties under hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com