Graphene oxide quantum dot solution and preparation method thereof

A technology of graphene quantum dots and solutions, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., to achieve excellent physical properties, improved performance, convenient operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

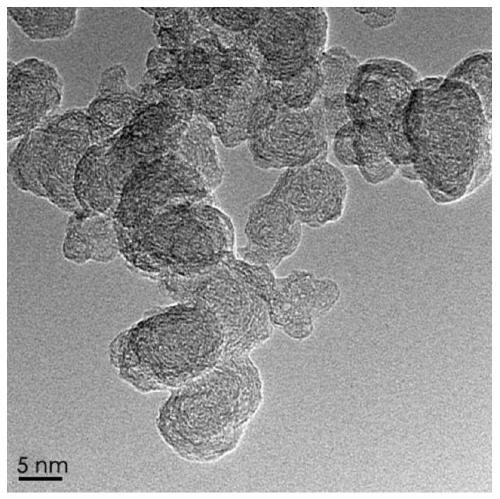

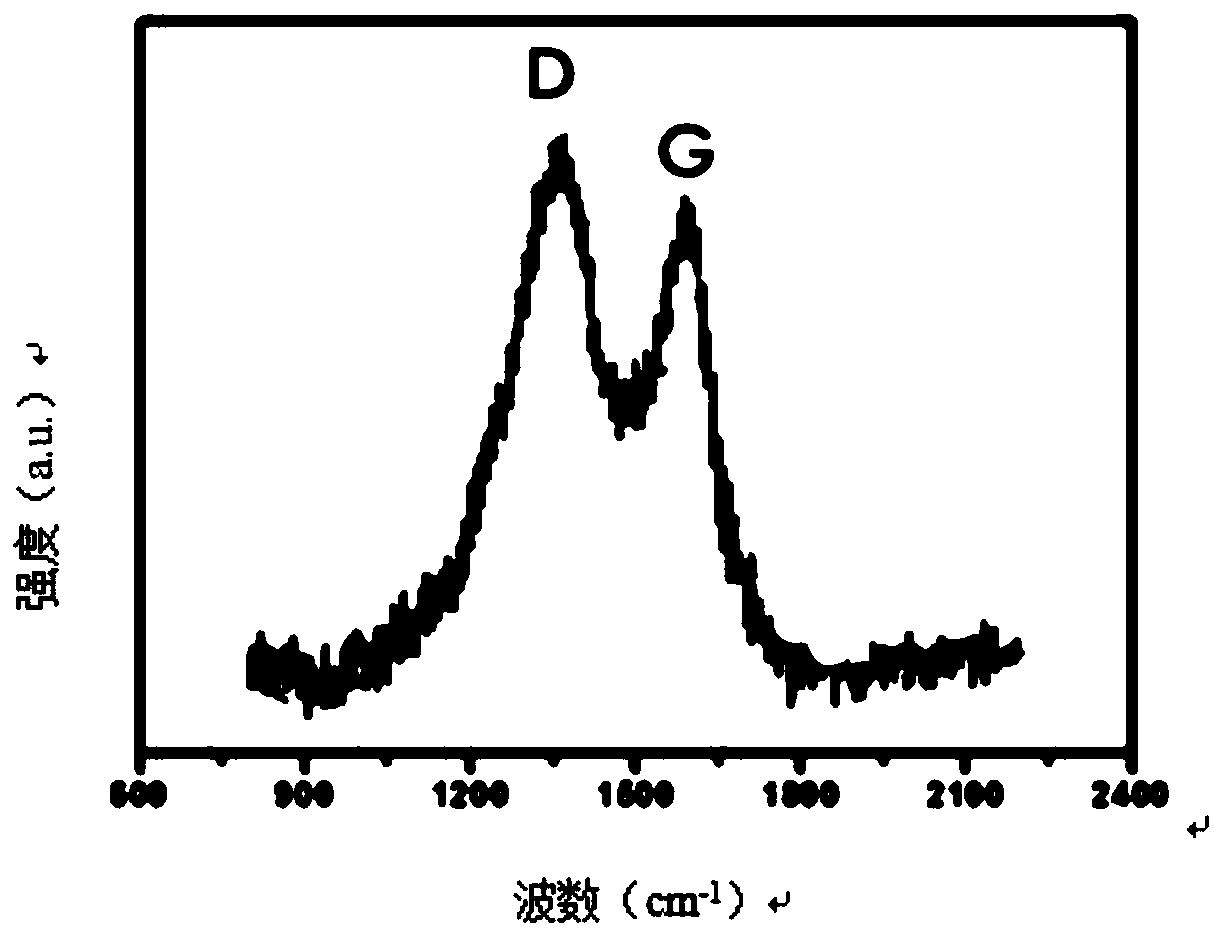

[0028] The invention provides a kind of preparation method of graphene oxide quantum dot solution, comprises the steps:

[0029] 1) expanding the expanded graphite at high temperature to obtain graphite worms;

[0030] 2) shearing the graphite worms described in step 1), and then uniformly dispersing them in a solvent containing a polymer dispersant to obtain a graphite worm dispersion;

[0031] 3) using a laser beam to irradiate the graphite worm dispersion in step 2) to obtain a graphite worm suspension;

[0032] 4) Centrifuge and filter the graphite worm suspension described in step 3 to obtain a graphene oxide quantum dot solution.

[0033] On the basis of the above-mentioned technical solutions, the present invention may also have the following further specific selections or optimization selections.

[0034] Specifically, the expansion temperature of the expanded graphite is 900-1100 degrees Celsius, preferably 1000 degrees Celsius.

[0035] Specifically, the expanded ...

Embodiment 1

[0044] Expand the expanded graphite with a mesh number of 100 and an expansion ratio of 100 times at 900 degrees Celsius to obtain graphite worms, and uniformly disperse the graphite worms into an aqueous solution containing pvp at a mass concentration of 0.5%, so that the mass percentage of graphite worms is 2%. , the laser beam with a wavelength of 10nm, an energy of 2000mJ, and a pulse frequency range of 30Hz is irradiated into the graphite worm dispersion (the processing capacity is 3kg / h powder), and the obtained suspension is centrifugally filtered. The speed of the centrifuge is 8000r / min, the centrifugation time is 20min, and the graphene oxide quantum dot solution is obtained.

Embodiment 2

[0046] Expand graphite with a mesh number of 2000 and an expansion rate of 500 times at 1100 degrees Celsius to obtain graphite worms, and uniformly disperse the graphite worms into a 0.5% NMP solution containing cmc so that the mass percentage of graphite worms is 2 %, irradiate a laser beam with a wavelength of 50nm, an energy of 2500mJ, and a pulse frequency range of 70Hz into the dispersion of graphite worms (the processing capacity is 4kg / h powder), and the obtained suspension is centrifugally filtered, and the speed of the centrifuge is 9000r / min, and the centrifugation time is 30min to obtain a graphene oxide quantum dot solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com