Compound brewing powder of grains and mixed beans with low sugar and high fiber as well as preparation method of brewing powder

A technology for mixing powder and miscellaneous beans, which is applied in the fields of oligosaccharide-containing food ingredients, food science, polysaccharide/gum-containing food ingredients, etc. Hygiene and nutritional benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

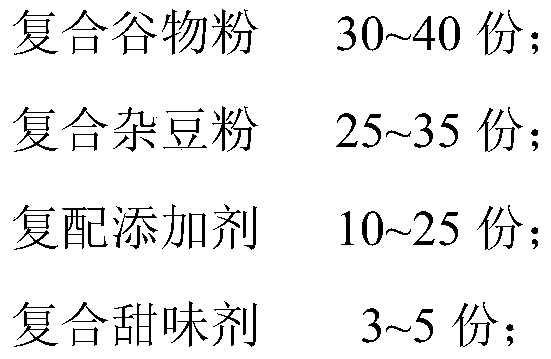

[0061] A low-sugar and high-fiber cereal mixed bean compound brewing powder, calculated in parts by weight, its raw materials include:

[0062]

[0063] The raw materials of the compound grain flour include glutinous rice, brown rice and tartary buckwheat germ rice, and the weight ratio of glutinous rice, brown rice and tartary buckwheat germ rice is 24:10:8; the raw materials of the compound miscellaneous bean flour include chickpeas, red beans and The weight ratio of white kidney beans, chickpeas, red beans and white kidney beans is 19:7:2; the raw materials of the compound additive include resistant dextrin, inulin, ultrafine wheat bran powder and soybean soluble polysaccharides, and the The weight ratio of resistant dextrin, inulin, superfine wheat bran powder and soybean soluble polysaccharide is 45:10:15:2; the raw materials of the compound sweetener include stevioside, mogroside, fructooligosaccharide and low The weight ratio of xylosaccharide, stevioside, mogroside,...

Embodiment 2

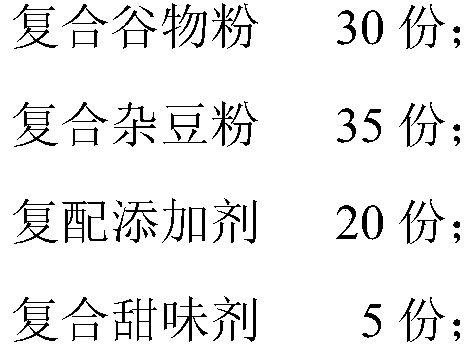

[0078] A low-sugar and high-fiber cereal mixed bean compound brewing powder, calculated in parts by weight, its raw materials include:

[0079]

[0080] The raw materials of the compound grain flour include glutinous rice, brown rice and tartary buckwheat germ rice, and the weight ratio of glutinous rice, brown rice and tartary buckwheat germ rice is 24:10:8; the raw materials of the compound miscellaneous bean flour include chickpeas, red beans and The weight ratio of white kidney beans, chickpeas, red beans and white kidney beans is 19:7:2; the raw materials of the compound additive include resistant dextrin, inulin, ultrafine wheat bran powder and soybean soluble polysaccharides, and the The weight ratio of resistant dextrin, inulin, superfine wheat bran powder and soybean soluble polysaccharide is 45:10:15:2; the raw materials of the compound sweetener include stevioside, mogroside, fructooligosaccharide and low The weight ratio of xylosaccharide, stevioside, mogroside,...

Embodiment 3

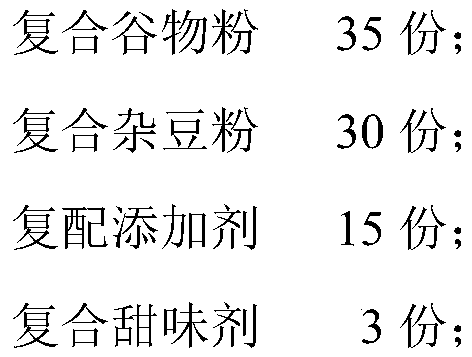

[0095] A low-sugar and high-fiber cereal mixed bean compound brewing powder, calculated in parts by weight, its raw materials include:

[0096]

[0097] The raw materials of the compound grain flour include glutinous rice, brown rice and tartary buckwheat germ rice, and the weight ratio of glutinous rice, brown rice and tartary buckwheat germ rice is 18:15:9; the raw materials of the compound miscellaneous bean flour include chickpeas, red beans and The weight ratio of white kidney beans, chickpeas, red beans and white kidney beans is 17:7:4; the raw materials of the compound additive include resistant dextrin, inulin, ultrafine wheat bran powder and soybean soluble polysaccharides, and the The weight ratio of resistant dextrin, inulin, superfine wheat bran powder and soybean soluble polysaccharide is 30:20:10:1; the raw materials of the compound sweetener include stevioside, mogroside, fructooligosaccharide and low The weight ratio of xylosaccharide, stevioside, mogroside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com