Modified sericite for impact-resistant polyolefin cable material and preparation method thereof

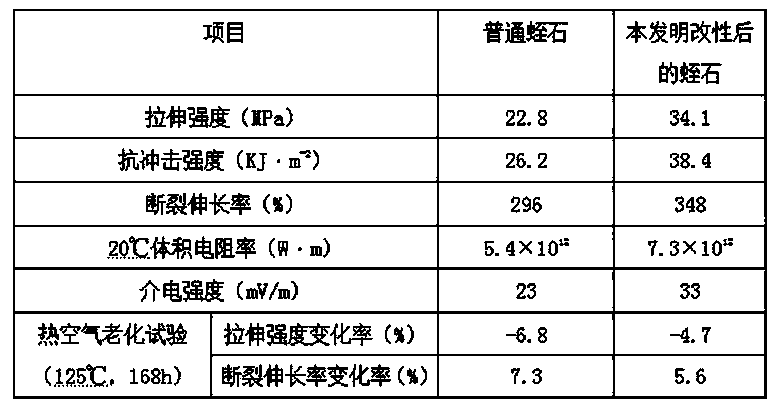

A technology of polyolefin and sericite, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of different interface properties and poor compatibility, and achieve improved compatibility, high tensile strength, Excellent elongation at break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A modified sericite for impact-resistant polyolefin cable materials, made of the following raw materials by weight (kg): Sericite 75, molybdenum boride 18, trimellitate triglyceride 12, fumed silica 16, carbon fiber Powder 11, polymerized rosin 4, 2,5-di-tert-butyl hydroquinone 2.5, rice bran wax 5, dimethyl oxalate 8, 2,4,6-tribromophenyl acrylate 10, aluminum distearate 3. Dimethyl propane carboxylate 5, ytterbium oxide 2.5, diethylaminoethyl methacrylate 4, zinc pyrithione 1.5, bisphenol A epichlorohydrin polymer isostearate 6, additives 4;

[0012] The additives are mixed from the following raw materials by weight (kg): neopentyl glycol diisocaprylate 4, zinc isooctanoate 2, N, N-bis(2-hydroxyethyl) alkylamine 2.5, glycerin Polyethylene oxide monostearate 1.5, tri-n-butylamine 3.5, white oil 6, lauryl mercaptan 3.5, dimer di(2-ethylhexyl) phosphate 2.5, titanium triisostearate Isopropyl ester 1.5, trimethylolpropane trioleate 4.

[0013] The preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com