Denitrification and algae removal-enhanced raw water biomembrane pretreatment technology device and method

A process device and biofilm technology, which is applied in the field of raw water biofilm pretreatment process devices, can solve problems that rarely involve the simultaneous removal of nitrogen and algae, and achieve the effect of reducing treatment risks and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

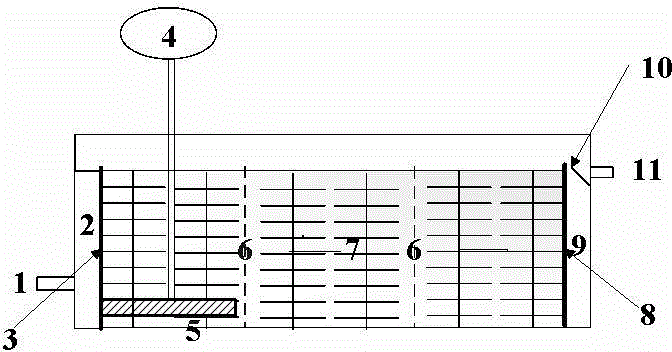

[0025] The reactor body is in the shape of a cuboid, and the effective volume of the reactor is 64 L. The ratio of the length, width and height of the device is 5:0.5:1 respectively; the inlet water distribution plate 3 and the outlet water distribution plate 8 are perforated sieve plates with uniform holes Distributed on the sieve plate, the pore size is 1 cm, and the ratio of the total pore area S1 to the total area S2 of the sieve plate is 0.2:1; the aeration tube 5 is arranged at the front end of the reactor, and the distance from the bottom of the reactor is 5 cm. The horizontal area S3 of the gas zone accounts for 10% of the total area S4 at the bottom of the reactor; the aperture size of the mesh screen 6 is 0.5 cm, and the distribution position is 0.3 times the length of the reactor, and there are two locations.

[0026] The filler filled in the device is the elastic filler of the pre-hanging film, and the biomass attached to the carrier is 0.95 mg TOC g -1 Carrier: D...

Embodiment 2

[0028] A brand-new elastic packing was used, the gas-liquid ratio was 1:1, the DO concentration in the reactor was 1.8 mg / L, and the rest of the conditions were the same as in Example 1. Due to the use of new fillers, on the 31st day of operation, the chlorophyll content of the influent and effluent water of the reaction device did not change significantly. After the biofilm was formed, the chlorophyll was significantly removed, and when the operation reached 101 days, no chlorophyll content was detected in the effluent of the reactor (incoming The water chlorophyll level is the same as in Example 2). During the start-up phase of the reactor, the operating performance fluctuated greatly compared with Example 2, but after a period of operation, the concentration of ammonia nitrogen in the effluent was still as low as 0.37±0.19 mg / L, meeting the 0.5 mg / L requirement specified in GB5749-2006.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com