Active compensation heat preservation method and pipeline heat preserving structure

A pipeline thermal insulation and active compensation technology, applied in pipeline heating/cooling, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of large investment in secondary heating of hot gas, long thermal balance time, and high thermal insulation cost, and achieve shortened The effect of thermal equilibration time, reduction of insulation costs, and reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

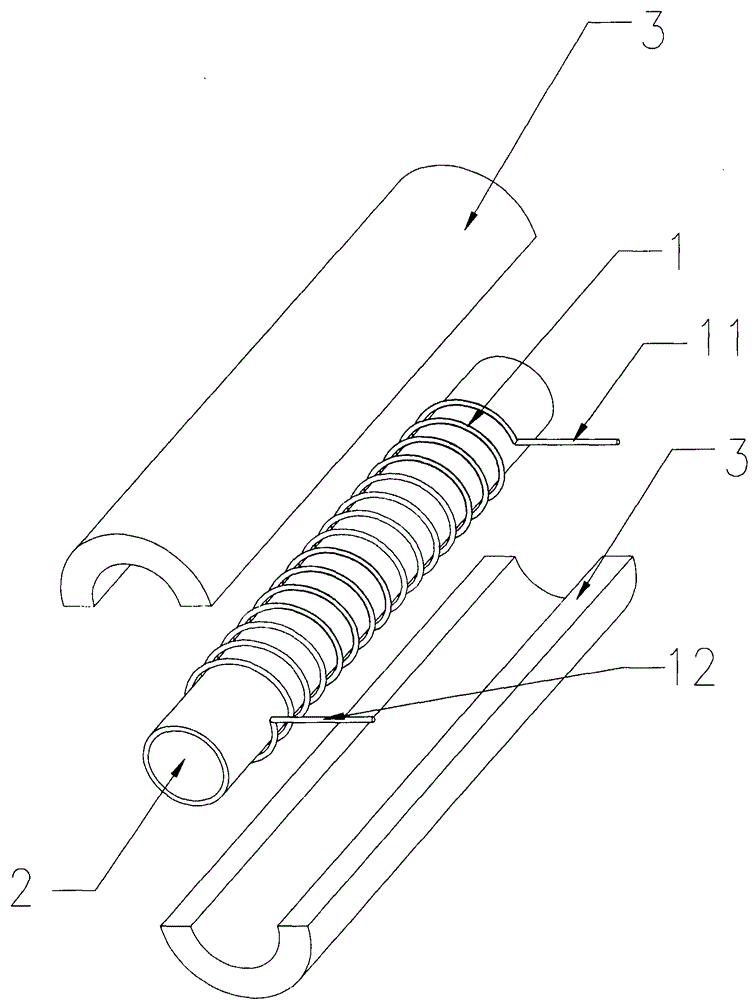

[0020] See attached figure 1 , The electromagnetic induction coil 1 is arranged between the surface of the pipeline 2 and the insulation layer 3, and the outgoing lines 11 and 12 of the induction coil are connected to the induction power supply.

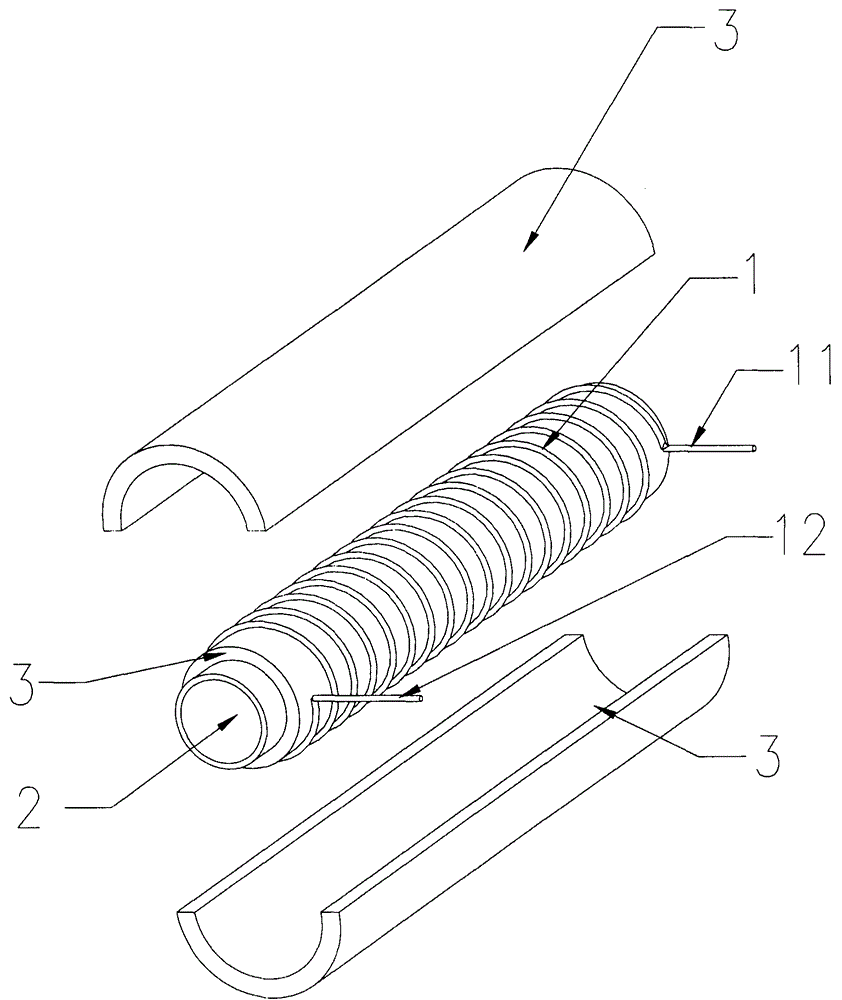

[0021] See attached figure 2 , The electromagnetic induction coil 1 is arranged in the pipe insulation layer 3, and the outgoing lines 11 and 12 of the induction coil are connected to the induction power supply.

[0022] The electromagnetic induction coil 1 is an electromagnetic induction source, and the pipeline 2 is an electromagnetic induction heating body.

[0023] Implementation method process:

[0024] An electromagnetic induction coil 1 is set between the surface of the pipeline 2 and the insulation layer 3 or in the pipeline insulation layer 3, and the pipeline 2 is used as an electromagnetic induction heating element; according to the material parameters of the insulation layer 3 and the fluid parameters in the pipeline 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com