Heat-conduction insulation cable sheath material and preparation method thereof

A cable sheath material, thermal insulation technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of power cable sheath aging, working temperature rise, line short circuit, etc., to achieve good thermal stability, The effect of excellent corrosion resistance, good electrical insulation and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

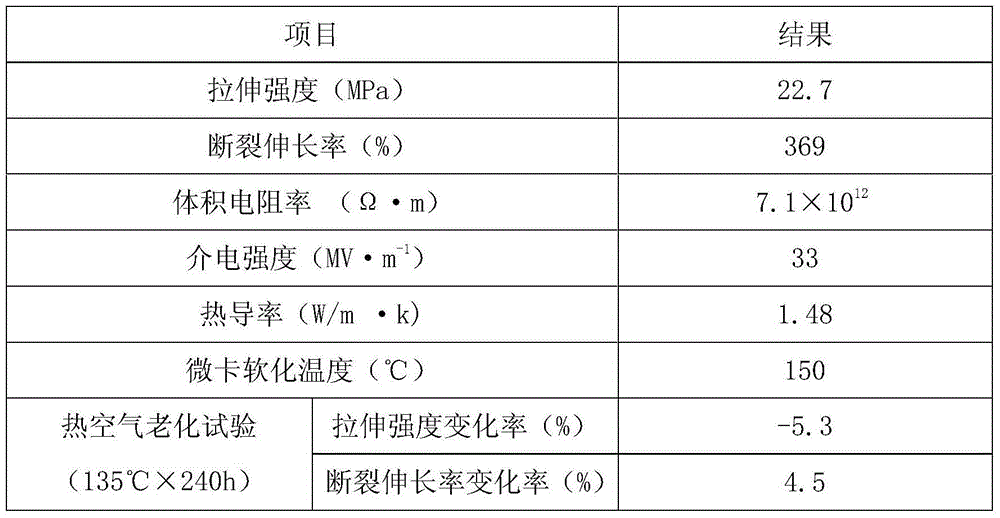

Examples

Embodiment Construction

[0012] A heat-conducting insulating cable sheath material, made of the following raw materials in weight (kg): linear low-density polyethylene 40, COC resin 20, polyphenylene sulfide 12, nano-titanium carbide 18, nano-zirconium boride 12, silver powder 8. Trimethylpentanediol 10, hydrated magnesium silicate superfine powder 7, dimerized linoleic acid 4, ethylene bis(12-hydroxy) stearic acid amide 3, stannous pyrophosphate 1.5, polyhexamethylene diphosphate Acid-1,4-butylene glycol ester diol 5, glycerol tribenzoate 8, hydroxyaluminum distearate 2.5, 2-mercaptoimidazoline 1, ethylhexyl methoxycinnamate 1, 3, 0.8 isooctyl 5-di-tert-butyl-4-hydroxyphenylpropionate, additive 6;

[0013] The preparation method of described auxiliary agent is as follows: a, get the raw material of following weight (kg): earthy graphite powder 12, zinc oxide 4,5A molecular sieve powder 6, expanded perlite powder 8, dioctyl terephthalate 10, Tallow amine polyoxyethylene ether 3, dicyclopentadiene 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com