Preparation method of Cu(NH3)4ATZ.2H2O

A technology of ammonia water and sodium azotetrazole, which is applied in the direction of copper organic compounds, can solve the problems of no use value and long synthesis time, and achieve the effect of simple destruction method, short synthesis time and convenient practical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Turn on the water bath to raise the temperature to 50-55°C, add 0.0034mol of 5,5'-azotetrazole sodium solution into the compounder and start stirring, put it in the water bath as the bottom solution, and dissolve 0.0034mol of copper sulfate in an appropriate amount of Heat and dissolve in distilled water in the same water bath. When the temperature in the compounder reaches 50-55°C, quickly add 2ml of 25-28% ammonia water, and pour copper sulfate solution into it for compound reaction after 1 minute. Continue to react for 5 minutes after the feeding is completed; then water-cool the compounder, and the temperature of the feed liquid drops below 40°C, then carry out discharge, suction filtration, water washing twice, ethanol dehydration twice, and drying at 40°C for 4 hours to finally obtain Green granular finished product with a yield of 95.5%.

Embodiment 2

[0019] Turn on the water bath to raise the temperature to 50-55°C, add 0.0034mol of 5,5'-azotetrazole sodium solution into the compounder and start stirring, put it in the water bath as the bottom solution, and dissolve 0.0037mol of copper sulfate in an appropriate amount of Heat and dissolve in distilled water in the same water bath. When the temperature in the compounder reaches 50-55°C, quickly add 2ml of 25-28% ammonia water, and pour copper sulfate solution into it for compound reaction after 1 minute. Continue to react for 10 minutes after the feeding is completed; then water-cool the compounder, and the temperature of the feed liquid drops below 40°C, that is, discharge, suction filter, wash with water twice, dehydrate with ethanol twice, and dry at 40°C for 4 hours to finally get Green granular finished product with a yield of 96.3%.

Embodiment 3

[0021] Turn on the water bath to raise the temperature to 50-55°C, add 0.0034mol of 5,5'-azotetrazolium sodium solution into the compounder and start stirring, put it in the water bath as the bottom solution, and dissolve 0.0041mol of copper sulfate in an appropriate amount of Heat and dissolve in distilled water in the same water bath. When the temperature in the compounder reaches 50-55°C, quickly add 2ml of 25-28% ammonia water, and pour copper sulfate solution into the compound reaction after 2 minutes. Continue to react for 5 minutes after the feeding is completed; then water-cool the compounder, and the temperature of the feed liquid drops below 40°C, then carry out discharge, suction filtration, water washing twice, ethanol dehydration twice, and drying at 40°C for 4 hours to finally obtain Green granular finished product with a yield of 95.1%.

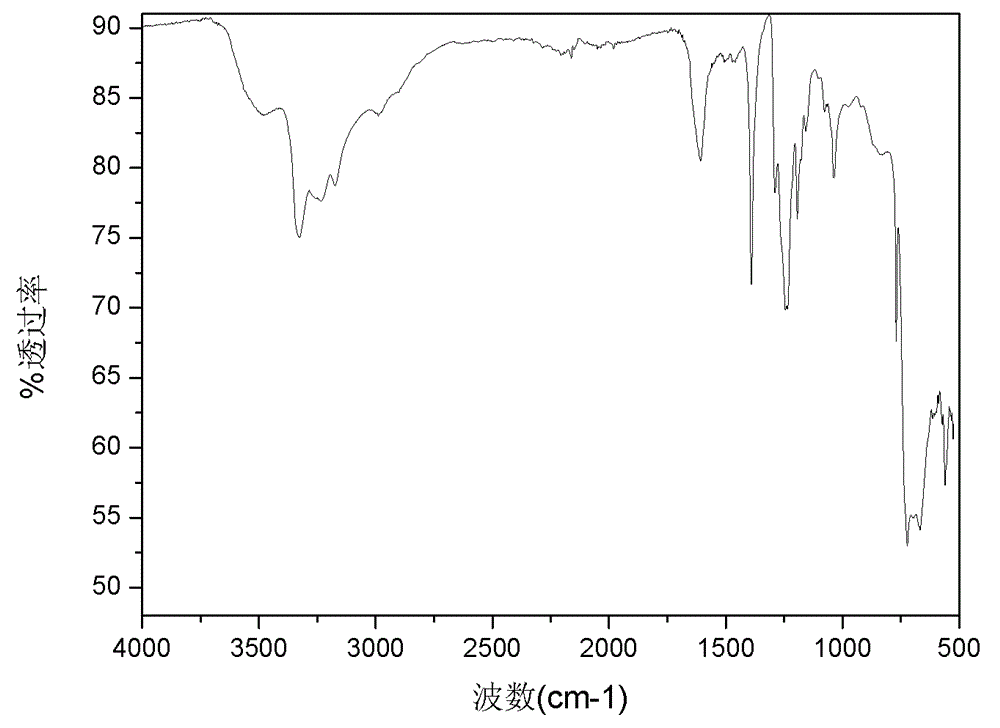

[0022] (1) Elemental analysis and infrared characterization:

[0023] Adopt the Cu(NH of embodiment 1 preparation 3 ) 4 AT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com