Coral reef stratum hole filling grouting material and use method thereof

A hole filling and grouting technology, applied in the field of geotechnical engineering, can solve the problems of insufficient strength, easy collapse, different hole sizes, etc., achieve high strength and early strength, good water resistance and dispersion performance, and improve water resistance and dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of grouting material for filling holes in coral reef strata provided in this embodiment and its application method are as follows:

[0025] 1) Preparation of grouting material: 70% cement, 10% limestone powder, 10% zeolite powder, 0.7% fumed silica, 8.5% expansion agent, 0.54% powder polycarboxylate superplasticizer, cellulose Ether 0.2%, silicone defoamer 0.02%, sodium glucose 0.04%, use a homogenizer to homogenize for 5 minutes.

[0026] 2) Preparation of grouting material slurry: add water with 27% of the grouting material mass according to the mass ratio, use a high-speed mixer with a rotation speed greater than 1000 rpm to stir and make slurry, and stir for 6 minutes to obtain a special slurry.

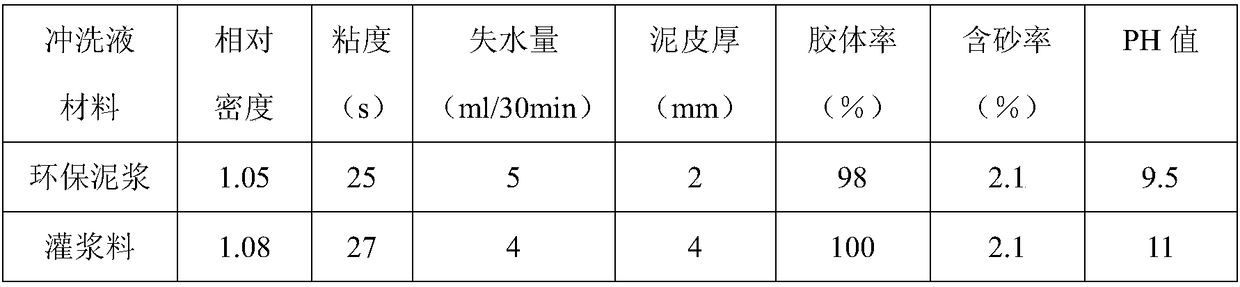

[0027] 3) The hole filling method of coral reef formation based on the above grouting materials: the reverse circulation rotary drilling method is used to form holes in the pile forming process, the mud wall is used in the hole forming process, and the mud regulator...

Embodiment 2

[0031] A kind of grouting material for filling holes in coral reef strata provided in this embodiment and its application method are as follows:

[0032] 1) Preparation of grouting material: according to the mass percentage of each component, cement 60%, limestone powder 23%, zeolite powder 8%, fumed silica 0.5%, expansion agent 7.3%, powder polycarboxylate superplasticizer 0.81%, xanthan Glue 0.31%, silicone defoamer 0.03%, sodium glucose 0.05%, use a homogenizer to homogenize for 5 minutes.

[0033] 2) Preparation of grouting material slurry: add water with 27% of the grouting material mass according to the mass ratio, use a high-speed mixer with a rotation speed greater than 1000 rpm to stir and make slurry, and stir for 6 minutes to obtain a special slurry.

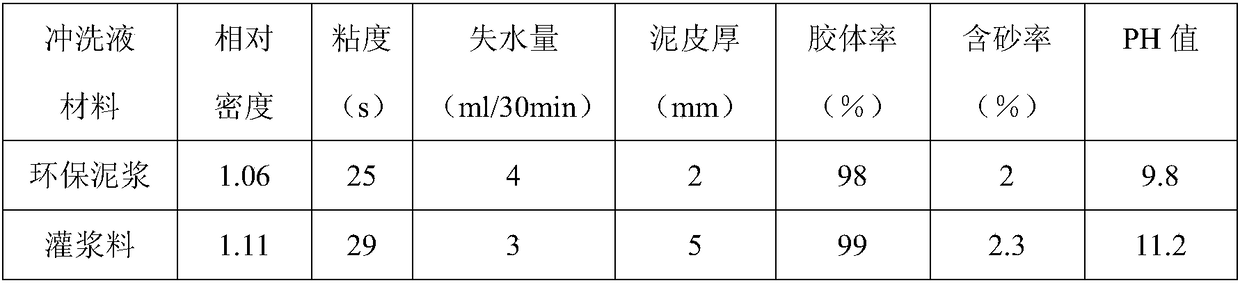

[0034] 3) The hole filling method of coral reef formation based on the above grouting materials: the reverse circulation rotary drilling method is used to form holes in the pile forming process, the mud wall is used i...

Embodiment 3

[0038] A kind of grouting material for filling holes in coral reef strata provided in this embodiment and its application method are as follows:

[0039]1) Preparation of grouting material: according to the mass percentage of each component, cement 65%, limestone powder 15%, zeolite powder 9%, fumed silica 0.85%, expansion agent 9%, powder polycarboxylate superplasticizer 0.85%, cellulose 0.23% ether, 0.02% silicone defoamer, 0.05% sodium glucose, and homogenize for 5 minutes with a homogenizer.

[0040] 2) Preparation of grouting material slurry: add water with 27% of the grouting material mass according to the mass ratio, use a high-speed mixer with a rotation speed greater than 1000 rpm to stir and make slurry, and stir for 6 minutes to obtain a special slurry.

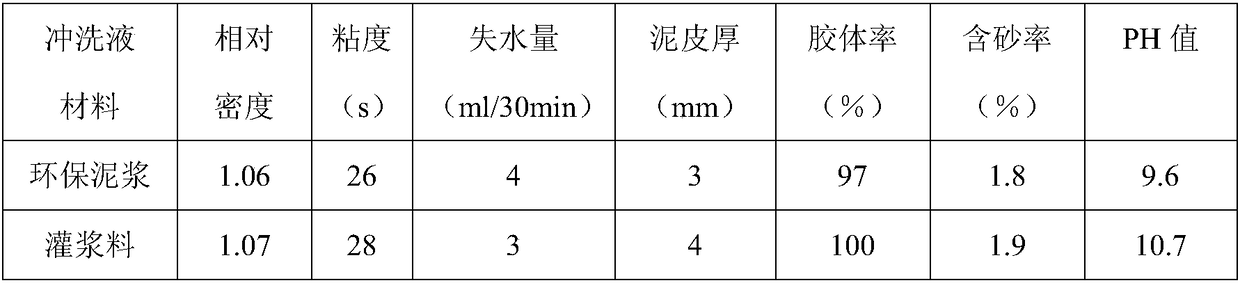

[0041] 3) The hole filling method of coral reef formation based on the above grouting materials: the reverse circulation rotary drilling method is used to form holes in the pile forming process, the mud wall is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com