A kind of CEO2 base scr catalyst and preparation method thereof

A technology of SCR catalysts and oxides, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of anti-sulfurization, weak anti-hydrothermal aging performance, and limited use of catalysts, so as to improve the resistance Vulcanization performance, cost reduction, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

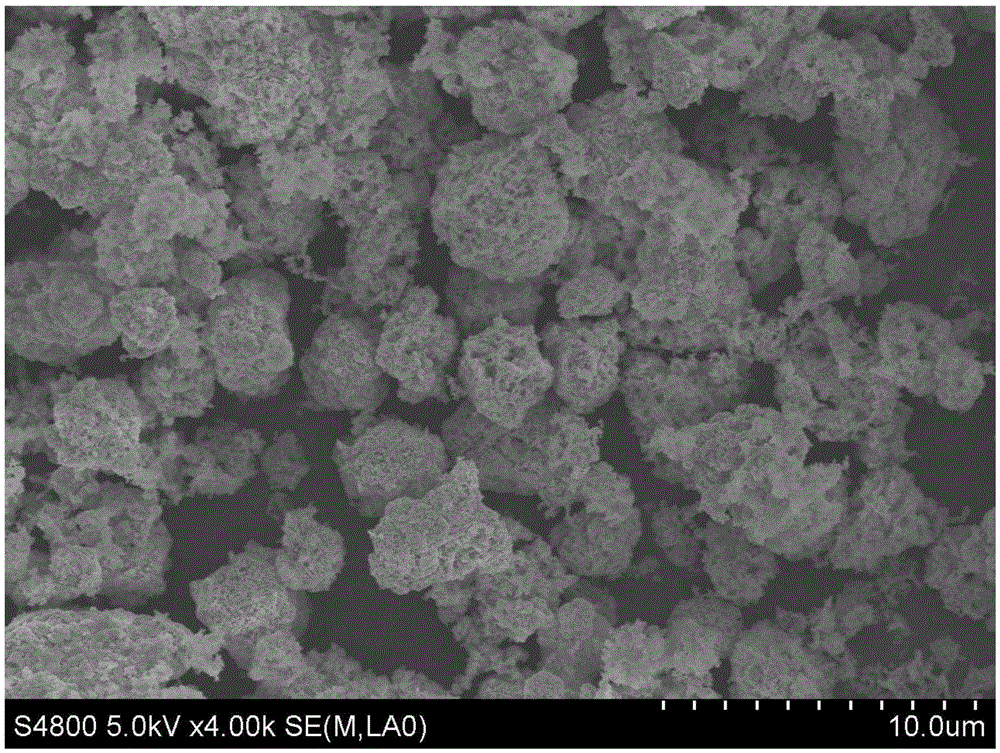

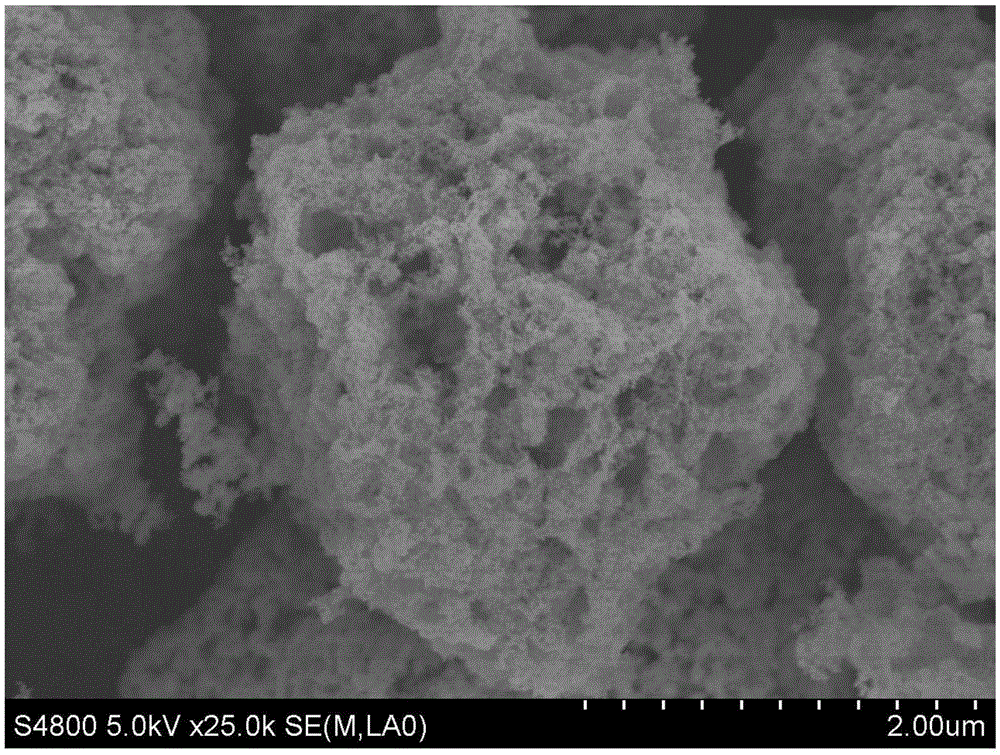

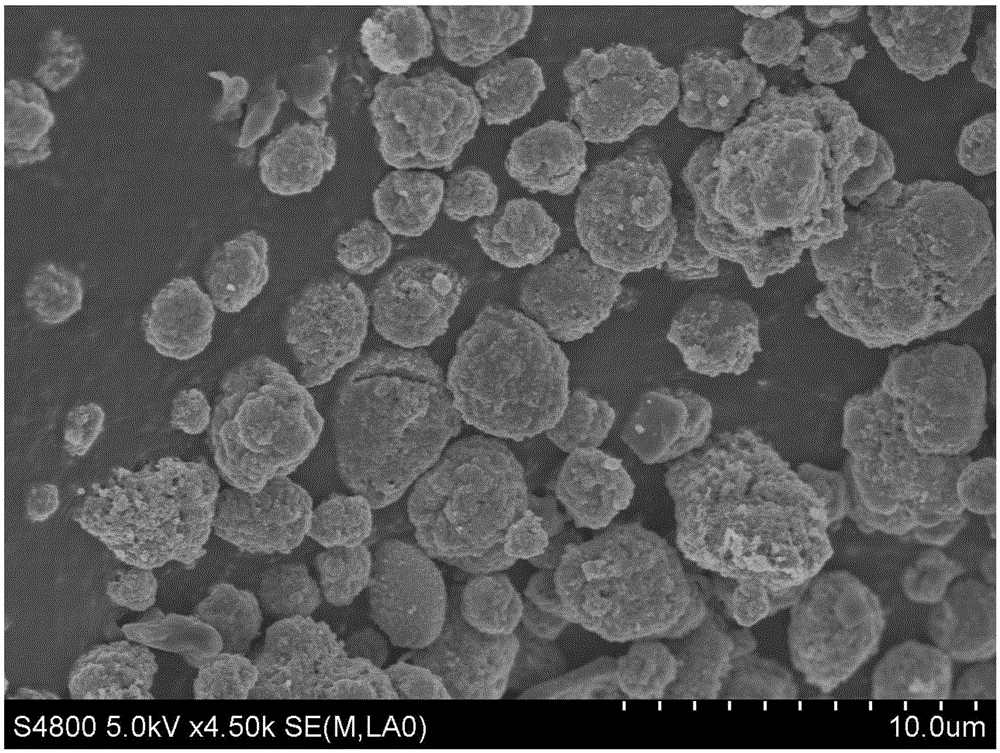

Image

Examples

experiment example 1

[0025] Experimental Example 1: Prepared by dipping method.

[0026] 1) Take a certain amount of CeO 2 The cerium-zirconium solid solution powder accounts for 80 wt%, and the selected amount ensures that the mass fraction of the metal oxide in the whole catalyst is 90%. The powder can only contain CeO 2 , the reason why doped ZrO 2 , because doping ZrO 2 After that, the CeO can be increased 2 Stability during catalytic reduction reactions. Similarly, the metal oxide powder can also be doped with Al 2 o 3 or SiO 2 .

[0027] 2) Take a certain amount of (NH 4 ) 2 HPO 4 and ZrOCl 2 ·8H 2 O, the selected amount guarantees PO 4 3- +Zr 4+ The mass fraction of the heteropolyacid material that forms accounts for the whole catalyst that makes afterwards is 10%, Zr 4+ with PO 4 3- Dissolve in deionized water at a molar ratio of 1:1 to form a clear aqueous solution, and Zr in the aqueous solution 4+ and PO 4 3- The sum of the ion concentrations is 1molL -1 .

[002...

experiment example 2

[0036] Experimental example 2: the same as the preparation process of experimental example 1, the difference is only: the difference in quality, so that the massfraction of the metal oxide accounted for the whole catalyst made is 80%, the massfraction of porous heteropolyacid material is 20%. Zr in heteropoly acid substances 4+ and PO 4 3- The molar ratio is still 1. The prepared catalyst was designated as A-2.

[0037] Test the selective catalytic reduction performance of the catalyst A-2, and the selective catalytic reduction performance after sulfurization treatment and hydrothermal treatment. The test method is the same as that in Experimental Example 1 and will not be repeated here. The test calculation results are shown in Table 1.

experiment example 3

[0038] Experimental Example 3: the same preparation process as Experimental Example 1, the only difference is: the difference in quality makes the metal oxide account for 70% of the mass fraction of the whole catalyst made, and the mass fraction of the porous heteropolyacid substance is 30%. Zr in heteropoly acid substances 4+ and PO 4 3- The molar ratio is still 1. The prepared catalyst was designated as A-3.

[0039] Test the selective catalytic reduction performance of the catalyst A-3, and the selective catalytic reduction performance after sulfurization treatment and hydrothermal treatment. The test method is the same as that in Experimental Example 1 and will not be repeated here. The test calculation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com