Novel composite filter net for air purifier and preparation method thereof

An air purifier and filter technology, which is applied in the filter field, can solve the problems of short service life and large filter resistance, and achieve the effects of long service life, small filter resistance and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a composite filter screen for a novel air purifier, comprising the steps of:

[0025] (1) Etching the surface of the base layer, firstly configure an lye solution with a pH of 9 to 11 (one or more mixtures of sodium carbonate, sodium bicarbonate, sodium hydroxide, potassium carbonate, potassium bicarbonate, and potassium hydroxide) , and then immerse the stainless steel wire mesh in it, and treat it in a water bath at 60-80 °C for 2-6 hours to remove impurities such as oil stains covered on its surface, and then spray and wash it with clean water until the pH of the washing wastewater reaches 7.0 ~7.2 is enough, then it is transferred to 0.05 ~ 0.20moL / L Fe 3+ (Fe(NO 3 ) 3 , Fe 2 (SO 4 ) 3 , FeCl 3 ) or Cu 2+ (Cu(NO 3 ) 2 , CuSO 4 , CuCl 2 ) solution in a water bath at 40 to 70 °C for 3 to 6 hours, so as to engrave the surface and facilitate the subsequent modification of the surface of the substrate layer;

[0026] (2) Modifying the ...

Embodiment 1

[0030] A preparation method of a composite filter screen for a novel air purifier, comprising the steps of:

[0031] (1) First, configure a sodium carbonate solution with a pH of 10, then immerse the stainless steel wire mesh in it, and treat it in a water bath at 60 °C for 4 hours to remove impurities such as oil stains covered on its surface. It is then washed with water spray until the pH of the washing water is close to neutral. It was then transferred to 0.05moL / L Cu(NO 3 ) 2 The solution was treated in a water bath at 40°C for 6h;

[0032] (2) The stainless steel wire mesh was then transferred to the hydrothermal reactor, and 20wt% aluminum sol solution was added to it and treated under hydrothermal conditions at 110°C for 24h. The obtained filter screen was washed with water and dried at 120°C for 4h. Then transfer to 400 ℃ for 6h calcination, so as to support a layer of Al on its surface 2 O 3 coating, wherein the loading of the coating on the surface of the stain...

Embodiment 2

[0035] A preparation method of a composite filter screen for a novel air purifier, comprising the steps of:

[0036] (1) First configure potassium bicarbonate solution with pH 9, then immerse the stainless steel wire mesh in it, and treat it in a water bath at 80°C for 2 hours to remove impurities such as oil stains on its surface, and then spray it with clean water. until the pH of the washing water is close to neutral, then it is transferred to 0.20 moL / L Fe(NO 3 ) 3 The solution was treated in a water bath at 70°C for 3h;

[0037] (2) The stainless steel wire mesh was then transferred to a hydrothermal reactor, and a 35wt% silica sol solution was added to it and treated under hydrothermal conditions at 130°C for 12h. The obtained filter screen was washed with water and dried at 110°C for 4h. It was then transferred to 600 °C for 4 h to support a layer of SiO on its surface. 2 coating, wherein the loading of the coating on the surface of the stainless steel wire mesh is 1.4...

PUM

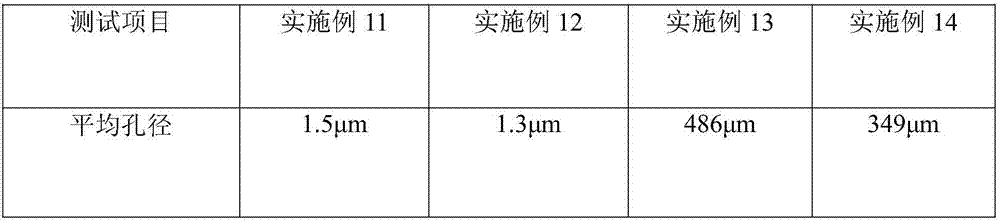

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com