Preparation method of high-emissivity energy-saving infrared radiation coating

A radiation coating and high emissivity technology, applied in coating, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as short service life, no visible energy saving effect, and decline in energy saving effect, so as to increase the furnace temperature and furnace temperature uniformity, reducing raw material consumption and maintenance costs, reducing the effect of flue gas temperature and exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

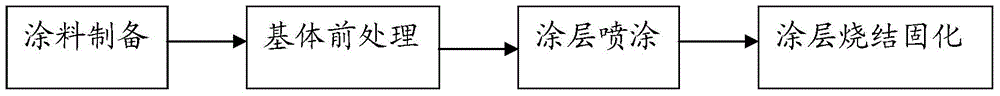

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a high-emissivity infrared energy-saving radiation coating, the steps are as follows:

[0042] (1) Coating preparation:

[0043] 64 parts of main components; 9 parts of additives; 6 parts of sintering agent; 400 parts of binder; 11 parts of additives,

[0044] The proportion of main components is: 20 parts of zirconium corundum, 10 parts of corundum micropowder, 4 parts of cobalt trioxide, 15 parts of chromium oxide green, 5 parts of iron oxide, and 10 parts of yttrium oxide;

[0045] The additive ratio is: 5 parts of silicon micropowder, 4 parts of magnesium oxide;

[0046] The ratio of additives is: cordierite 7 parts, boric acid 4 parts;

[0047] The sintering agent is bentonite;

[0048] The binder is an organic-inorganic composite binder, including 324 parts of silica sol, 26 parts of carboxymethyl cellulose, 35 parts of high-temperature composite glue solution, and 15 parts of ethyl silicic acid.

[0049] 64 parts of the main component, ...

Embodiment 2

[0058] A method for preparing a high-emissivity infrared energy-saving radiation coating, the steps are as follows:

[0059] (1) Coating preparation:

[0060] 122 parts of main components; 20 parts of additives; 15 parts of sintering agent; 579 parts of binder; 22 parts of auxiliary agents,

[0061] The proportion of main components is: 36 parts of zirconium corundum, 28 parts of corundum micropowder, 8 parts of cobalt trioxide, 25 parts of chromium oxide green, 10 parts of iron oxide, and 15 parts of yttrium oxide;

[0062] The additive ratio is: 10 parts of silicon micropowder, 10 parts of magnesium oxide;

[0063] The ratio of additives is: cordierite 14 parts, boric acid 8 parts;

[0064] The sintering agent is soft clay;

[0065] The binder is an organic-inorganic composite binder, including 450 parts of silica sol, 34 parts of carboxymethyl cellulose, 70 parts of high-temperature composite glue solution, and 25 parts of ethyl silicic acid.

[0066] 122 parts of the m...

Embodiment 3

[0075] A method for preparing a high-emissivity infrared energy-saving radiation coating, the steps are as follows:

[0076] (1) Coating preparation:

[0077] 93 parts of main components; 14.5 parts of additives; 10.5 parts of sintering agent; 489.5 parts of binder; 16.5 parts of additives,

[0078] Wherein the main components include the following components in parts by weight: 28 parts of zirconium corundum, 19 parts of corundum micropowder, 6 parts of dicobalt trioxide, 20 parts of chromium oxide green, 7.5 parts of iron oxide, and 12.5 parts of yttrium oxide;

[0079] The sintering agent is kaolin;

[0080] The binder includes the following components in parts by weight: 387 parts of silica sol, 30 parts of carboxymethyl cellulose, 20 parts of ethyl silicic acid, and 52.5 parts of high-temperature composite glue solution;

[0081] The auxiliary agent includes the following components in parts by weight: 10.5 parts of cordierite and 6 parts of boric acid.

[0082] Mix 93...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com