Weather-resistant PBT/AES alloy and preparation method thereof

A technology of weather resistance and PBT resin, which is applied in the field of high-strength impact resistance and weather resistance PBT/AES alloy and its preparation, can solve the problems of insufficient weather resistance of PBT resin, fast crystallization speed of PBT, large shrinkage of PBT, etc. Effects of shrinkage rate, increase in flexural modulus, and reduction in color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

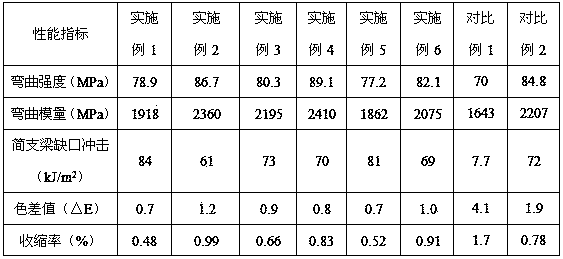

Examples

Embodiment 1

[0033] Dry 40 parts of PBT resin and 60 parts of AES resin at 100°C for 1 hour for later use; weigh 20 parts of 200 mesh light calcium carbonate and pour it into a high mixer, and then add 2 parts of silane coupling agent γ-aminopropyl tri Ethoxysilane was added and mixed for 2 minutes; then the dried PBT resin, AES resin, 10 parts of compatibilizer maleic anhydride grafted ABS, 0.3 parts of antioxidant tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester into the high mixer, after stirring again for 5 minutes, add the blend mixed in the high mixer into the twin-screw extruder for extrusion and granulation. The specific parameters of the twin-screw extruder are: the temperature of the first zone is 200°C, the temperature of the second zone is 225°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 245°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 250°C, and the temperature of...

Embodiment 2

[0035] Dry 80 parts of PBT resin and 20 parts of AES resin at 100°C for 2 hours for later use; weigh 5 parts of 800 mesh heavy calcium carbonate and pour it into a high mixer, and then add 0.2 parts of silane coupling agent γ-glycidyl ether oxygen Add propyltrimethoxysilane and mix for 5 minutes; add tetra[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.2 parts of antioxidant tris[2.4-di-tert-butylphenyl] phosphite were added to the high mixer, stirred again for 4 minutes and put into the high mixer The mixed blend is put into a twin-screw extruder for extrusion and granulation. The specific parameters of the twin-screw extruder are: the temperature of the first zone is 210°C, the temperature of the second zone is 235°C, the temperature of the third zone is 245°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 255°C, the temperature of the sixth zone is 250°C, and the temperature of the seventh zone is 250°C ℃,...

Embodiment 3

[0037] Dry 60 parts of PBT resin and 40 parts of AES resin at 100°C for 3 hours for later use; weigh 10 parts of 600 mesh light calcium carbonate and pour it into a high mixer, and then add 1 part of silane coupling agent γ-methacryloyl Add oxypropyltrimethoxysilane and mix for 8 minutes; then dry PBT resin, dried AES resin, 6 parts of compatibilizer maleic anhydride grafted ABS, 0.2 parts of antioxidant N, N' - Bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexamethylenediamine and 0.2 parts of antioxidant dioctadecyl thiodipropionate are added to the high mixer and stirred again After 10 minutes, put the blend mixed in the high mixer into the twin-screw extruder to extrude and granulate. The specific parameters of the twin-screw extruder are: the temperature of the first zone is 205°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 245°C, the temperature of the fifth zone is 250°C, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com