Preparation method for polyvinylidene fluoride/poly-dopamine-coated graphene nanocomposite

A technology of nano-composite materials and polyvinylidene fluoride, which is applied in the field of dielectric materials and nano-composite materials, can solve the problems of increasing dielectric loss, sharp increase in leakage loss, etc. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

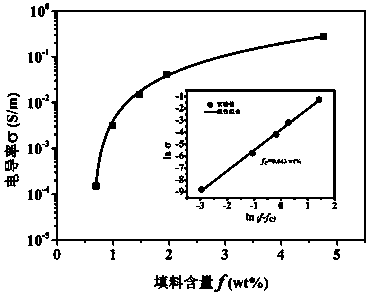

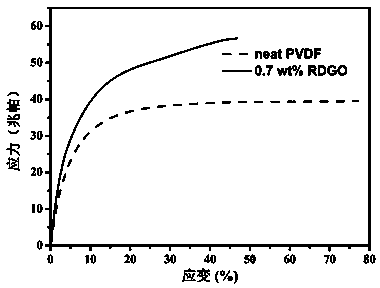

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: At 0°C, add 6g of graphite, 3g of sodium nitrate and 180mL of concentrated sulfuric acid into a three-neck flask, mix well, then add 18g of potassium permanganate, react for 2h, react at 35°C for 35 minutes, add 300mL of water at 98°C Stir and react for 3 hours, after cooling to room temperature, add 2 kg of water and 50 mL of 30% hydrogen peroxide, stir for 2 hours, repeatedly centrifuge and wash with deionized water until neutral, and disperse in water by ultrasonication for 30 minutes.

[0037] Step 2: Take 1 part by weight of graphene oxide obtained in step (1), and prepare its concentration to 2 mg / mL.

[0038]Step 3: Add dopamine hydrochloride to the 200 mL dispersion obtained in step (2), and prepare the concentration to 1.25 mg / mL.

[0039] Step 4: Add 6 mL of ammonia water dropwise to the mixed system obtained in step (3), adjust the pH value to be alkaline, keep the temperature of the water bath at 60°C, and stir for 12 hours to polymerize dopamine.

...

Embodiment 2

[0046] Step 1: At 0°C, add 6g of graphite, 3g of sodium nitrate and 180mL of concentrated sulfuric acid into a three-neck flask, mix well, then add 18g of potassium permanganate, react for 2h, react at 35°C for 35 minutes, add 300mL of water at 98°C Stir and react for 3 hours, after cooling to room temperature, add 2 kg of water and 50 mL of 30% hydrogen peroxide, stir for 2 hours, repeatedly centrifuge and wash with deionized water until neutral, and disperse in water by ultrasonication for 30 minutes.

[0047] Step 2: Take 1 part by weight of graphene oxide obtained in step (1), and prepare its concentration to 1 mg / mL.

[0048] Step 3: Add dopamine hydrochloride to the 400 mL dispersion obtained in step (2), and prepare the concentration to 0.8 mg / mL.

[0049] Step 4: Add 100 mL of 50mM Tris buffer (pH=8.5) to the mixed system obtained in step (3), keep the temperature of the water bath at 60°C, and stir for 24 hours to polymerize dopamine.

[0050] Step 5: The mixed syste...

Embodiment 3

[0056] Step 1: At 0°C, add 6g of graphite, 3g of sodium nitrate and 180mL of concentrated sulfuric acid into a three-neck flask, mix well, then add 18g of potassium permanganate, react for 2h, react at 35°C for 35 minutes, add 300mL of water at 98°C Stir and react for 3 hours, after cooling to room temperature, add 2 kg of water and 50 mL of 30% hydrogen peroxide, stir for 2 hours, repeatedly centrifuge and wash with deionized water until neutral, and disperse in water by ultrasonication for 30 minutes.

[0057] Step 2: Take 1 part by weight of graphene oxide obtained in step (1), and prepare its concentration to 2 mg / mL.

[0058] Step 3: Add dopamine hydrochloride to the 200 mL dispersion obtained in step (2), and prepare the concentration to 1.25 mg / mL.

[0059] Step 4: Add 6 mL of ammonia water dropwise to the mixed system obtained in step (3), adjust the pH value to be alkaline, keep the temperature of the water bath at 60°C, and stir for 12 hours to polymerize dopamine. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com