Method for degrading chitosan through microwave-enzyme method coupling

A technology of chitosan and chitosan solution, which is applied in the field of chitosan preparation, can solve the problems of high cost, poor product uniformity, and long degradation reaction cycle, and achieve the effect of low cost, low cost, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare buffer solution 100ml of pH=5 with acetic acid and sodium acetate, add 1g polymer chitosan (relative molecular mass (hereinafter abbreviated as Mw) 1.8 * 10 6 Da), its number-average molecular weight is 5.0×105Da-5.0×106Da) through high performance liquid phase measurement, fully stirred to make chitosan solution; then add 0.03g cellulase to chitosan solution, after stirring evenly, shell Pour the polysaccharide solution into the reaction bottle, put the reaction bottle into the microwave reactor, and pass nitrogen gas into the reaction bottle, control the temperature at 55°C, and microwave power 600W to carry out the degradation reaction. After 10 minutes, the microwave is heated to 100°C for Enzyme inactivation, the inactivation reaction time is 10-15min; use 1mol / L sodium hydroxide solution to adjust the pH value of the reaction solution to 7-8, then filter to remove the precipitate, and use the obtained filtrate to remove salt ions by dialysis Low molecular ...

Embodiment 2

[0019] Prepare buffer solution 100ml of pH=5 with acetic acid and sodium acetate, add 1g polymer chitosan (Mw=1.8×10 6 Da, number-average molecular weight 5.0×105Da-5.0×106Da), fully stirred to make chitosan solution; then add 0.03g cellulase in the chitosan solution, pour the solution into the reaction bottle after stirring evenly, and then Put the reaction bottle into a microwave reactor, and pass nitrogen gas into the reaction bottle, control the temperature at 55°C, and microwave power 600W to carry out the degradation reaction. After 60 minutes, the microwave temperature is raised to 100°C to inactivate the enzyme. The inactivation reaction time is 10- 15min; with 1mol / L sodium hydroxide solution, the pH value of the solution after the reaction is adjusted to 7-8, and then the precipitate is removed by filtration, and the obtained filtrate is lyophilized to obtain low molecular weight chitosan after removing salt ions by dialysis, and the yield is It is 82%; Measured by h...

Embodiment 3

[0021] The method step of degrading chitosan in the present embodiment is identical with embodiment 1 and embodiment 2, and the number average molecular weight of high molecular weight chitosan is 5.0 * 10 5 Da-5.0×10 6 Da, other relevant experimental data are shown in Table 1:

[0022]

[0023]

[0024] Table 1

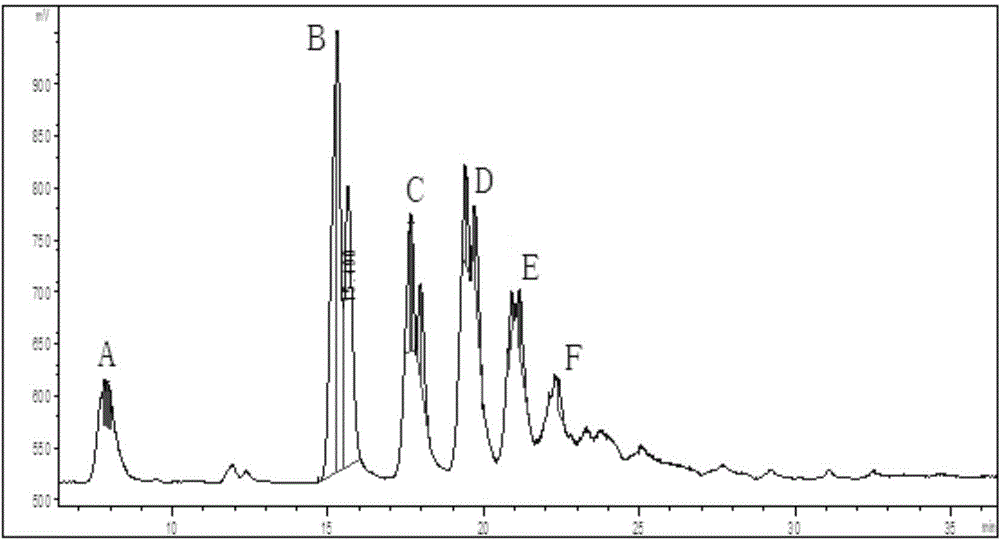

[0025] Wherein the product low-molecular-weight chitosan in example 10, surveys its degree of polymerization with high performance liquid chromatography, mainly contains trisaccharide to hexasaccharide, specifically as image 3 Shown; Know that compared with example by contrast example, the productive rate of enzymolytic chitosan under normal temperature is obviously lower than the productive rate of enzymatic chitosan under microwave heating condition, so the microwave-enzymatic method coupling degradation shell of the present invention design The glycan method has a high degradation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com