Inelastic collision and rolling viscous resistance particle coupling energy dissipation toolholder

A technology of inelastic collision and viscous resistance, applied in the direction of boring bars, etc., can solve the problems of poor machining accuracy and surface quality, restrict the boring process of deep hole parts, and cannot increase the diameter of the tool, so as to improve stability and precision, small structural changes, and obvious vibration suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

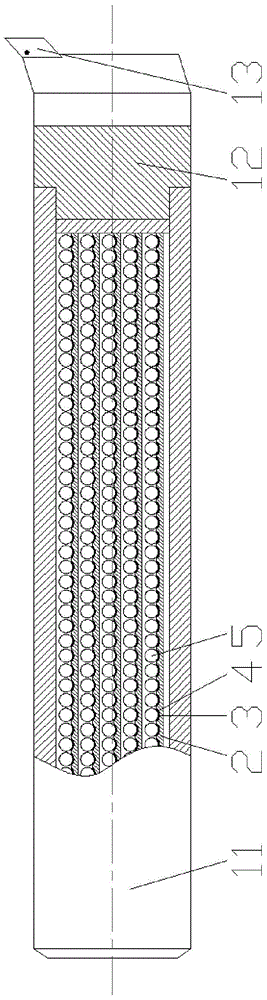

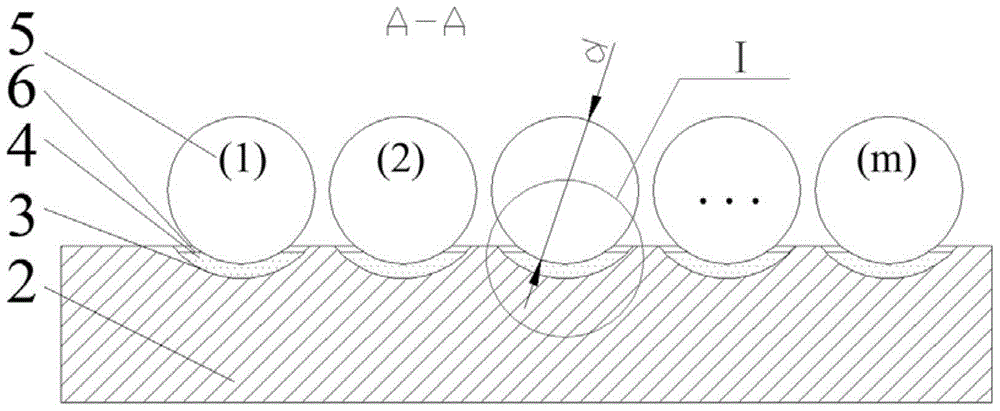

[0027] see Figure 1-7 , the embodiment of the present invention is provided with a cutter bar body 11, a cutter bar connector 12, a cutter head 13, and a coupling energy dissipation plate 2; a groove array is provided on the coupling energy dissipation plate 2, and each groove of the groove array 3 is provided with one surface low restitution coefficient particle 5 and at least two high surface viscous resistance polymer particles 4, the surface of the high surface viscous resistance polymer particle 4 is coated with a high polymer film 6, and the coupling energy dissipation plate 2 is provided with a fixing slot 7 for installing a coupling energy dissipation board.

[0028] The groove array can be set as an m×n groove array, m is the number of particle grooves in the longitudinal direction of the coupling energy dissipation plate 2 , and n is the number of particle grooves in the width direction of the coupling energy dissipation plate 2 .

[0029] The high surface viscous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com