Waste pyrolysis system with adjustable oil, gas and carbon and method

A waste and pyrolysis technology, applied in the field of waste resource treatment, can solve problems such as low calorific value, inability to effectively control quality, and inability to improve the quality of recovered oil, so as to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

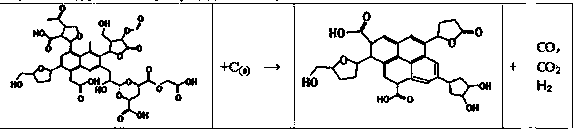

Method used

Image

Examples

Embodiment 1

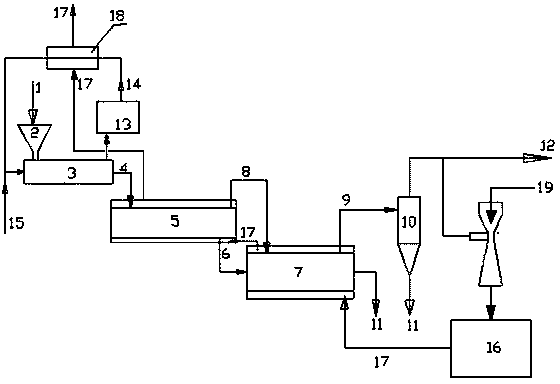

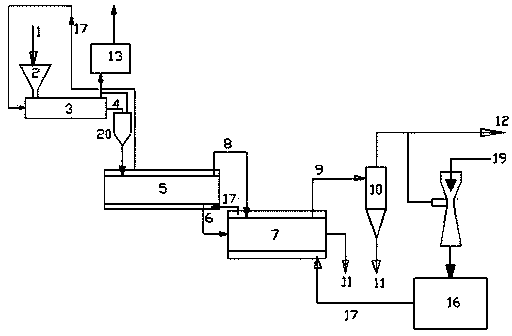

[0060] figure 2 A specific optimized implementation of the system and method provided by the present invention is shown. The system of this specific embodiment includes waste feed 1, feeder 2, pre-reaction section 3, pre-reacted material 4, main reactor 5, residual coke 6, conditioner 7, volatile matter 8, after conditioning Volatile matter 9, particle separator 10, residual coke after conditioning 11, clean volatile matter 12, gas scrubber 13, circulating gas 14, inert gas 15, combustion furnace 16, flue gas 17, circulating gas heater 18 and Combustible gas19.

[0061] In the system of this specific embodiment, by setting up corresponding pipeline connections, the purpose of quality adjustment of waste pyrolysis products oil, gas, and carbon can be realized in the following operation mode:

[0062] The waste 1 has a moisture content of 0-42% after preliminary pretreatment, and is fed to the pre-reaction section 3 by the feeder 2; then the pre-reacted material 4 is sent to ...

Embodiment 2

[0065] After the domestic waste in a county-level city is separated from wet components and sand by drum sieving1, the moisture content is 30%, the dry plastic content is 28%, and other components are waste paper, cloth, vegetation and branches, as shown in Table 1 :

[0066] Table 1 Composition of dry waste after dry and wet separation of waste in a certain city through a drum sieve

[0067] components percentage moisture content waste plastic 40% 30% the fabric 12% 32% Coarse food waste and vegetation 13% 35% paper 20% 30.02% Other residue 15% 24.00% total 100% 30% Chlorine content 1.6% Low calorific value on dry basis 15.664KJ / kg

[0068] When using the existing technology for processing, the garbage 1 in Table 1 is preheated or directly enters the main reactor 5 without preheating. When the working temperature of the main reactor 5 is 500 ° C, the volatile matter coming out of the main reactor 5...

Embodiment 3

[0072] A project deals with waste plastics separated from domestic waste and paper waste, hoping to recover oil from waste plastics. Waste plastics contain 60% polyethylene and polypropylene, 5.0% polyvinyl chloride (PVC), 18% impurities, and 17% comprehensive moisture content.

[0073] When using the existing technology to process, the waste plastic garbage 1 first melts or directly enters the main reactor 5 without melting. After condensation, 54% of oil and water (including 12% of water and 42% of anhydrous oil), 19% of gas, and 27% of carbon (residual coke) 6 were obtained. After testing, the calorific value of oil is 39MJ / kg, the calorific value of gas is 26.78MJ / kg, the calorific value of residual coke is 10.3MJ / kg, and the kinematic viscosity of oil is 506mm 2 / s. The oil contains 1.08% chlorine, which has a serious impact on subsequent utilization.

[0074] Implemented by the system and method of the present invention, the waste plastic 1 has a moisture content of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com