A kind of preparation method of large-scale ceramic biscuit

A ceramic green body and large-size technology, which is applied in the field of preparation of large-size ceramic green bodies, to achieve the effects of simple preparation process, increased cross-linking degree, reduced shrinkage and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Preparation of an alumina biscuit with a solid content of 56vol% and a size of 400mm×50mm×10mm from a one-component gel system

[0049] The alumina ceramic powder used is produced by Sumitomo Chemical Co., Ltd., Japan, with an average particle size of about 0.45 μm;

[0050] Add 1.68g of cis-butene polymer with long and short chains into 110g of deionized water, mix and dissolve in water for 10min, then add 560g of alumina ceramic powder, mix and ball mill with a planetary ball mill for 30min, after mixing evenly, the obtained ceramic slurry is vacuum removed Inject the air into a plastic mold, seal it with a PVC film and put it in a 50°C constant temperature box for syneresis. After 24 hours of dehydration, take out the unsealed film, and put the ceramic green body gel into a constant temperature and humidity box (temperature: 40°C ; Humidity: 60%) and dry for 24 to 36 hours to obtain a good alumina ceramic body with a smooth surface. After testing, the ben...

Embodiment 2

[0054] Example 2: Preparation of ternary gel system Alumina biscuit with a size of 300mm×200mm×50mm Add 46.2ml of ammonium polyacrylate to 1.32kg of deionized water as a dispersant, add 6.71kg of alumina ceramic powder after mixing, and stir Ball mill mixing and ball milling for 60 minutes. After mixing evenly, add 98.3ml water-soluble epoxy resin SPE and continue ball milling for 10 minutes, so that SPE and ceramic slurry are fully mixed, then add 57.8ml 3,3'-diaminodipropylamine as a curing agent and stir for 5 minutes. The obtained ceramic slurry is vacuum-degassed and injected into a plastic mold, sealed with a PVC film and placed in a 40°C constant temperature box for syneresis. Dry in a constant humidity box (temperature: 40°C; humidity: 60%) for 48 to 60 hours to obtain a smooth and intact alumina ceramic body;

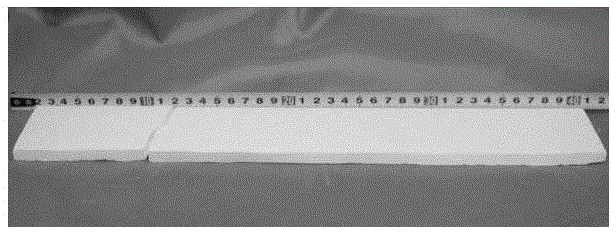

[0055] Figure 5 It is the photo of the green body after dehydration and drying obtained in Example 2 of the present invention, and the sample is complete wit...

Embodiment 3

[0056] Example 3: A zirconia green body with a syneresis size of 600mm×320mm×60mm in a one-component gel system was added to 14.4kg of deionized water to add 187.2g of a maleic butene polymer with a combination of long and short chains, mixed with water for 10 minutes, and then added 103.8kg Zirconia ceramic powder was mixed and milled for 60 minutes with a stirring ball mill. After mixing evenly, the obtained ceramic slurry was degassed in a vacuum and poured into a plastic mold. After sealing it with a PVC film, it was placed in a thermostat at 40°C for syneresis and dehydration for 96 Hours later, the film can be removed for the next step of drying;

[0057] Figure 6 It is a photograph of the ceramic green body gel in Example 3 of the present invention during the dehydration process, and a water layer is formed on the surface of the ceramic green body gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com