Antibacterial antistatic wood bamboo plastic floor and manufacturing method thereof

A manufacturing method and anti-static technology, applied in the field of plastic flooring, can solve the problems of anti-static and poor bacteriostatic effect, and achieve the effects of excellent mechanical properties, light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

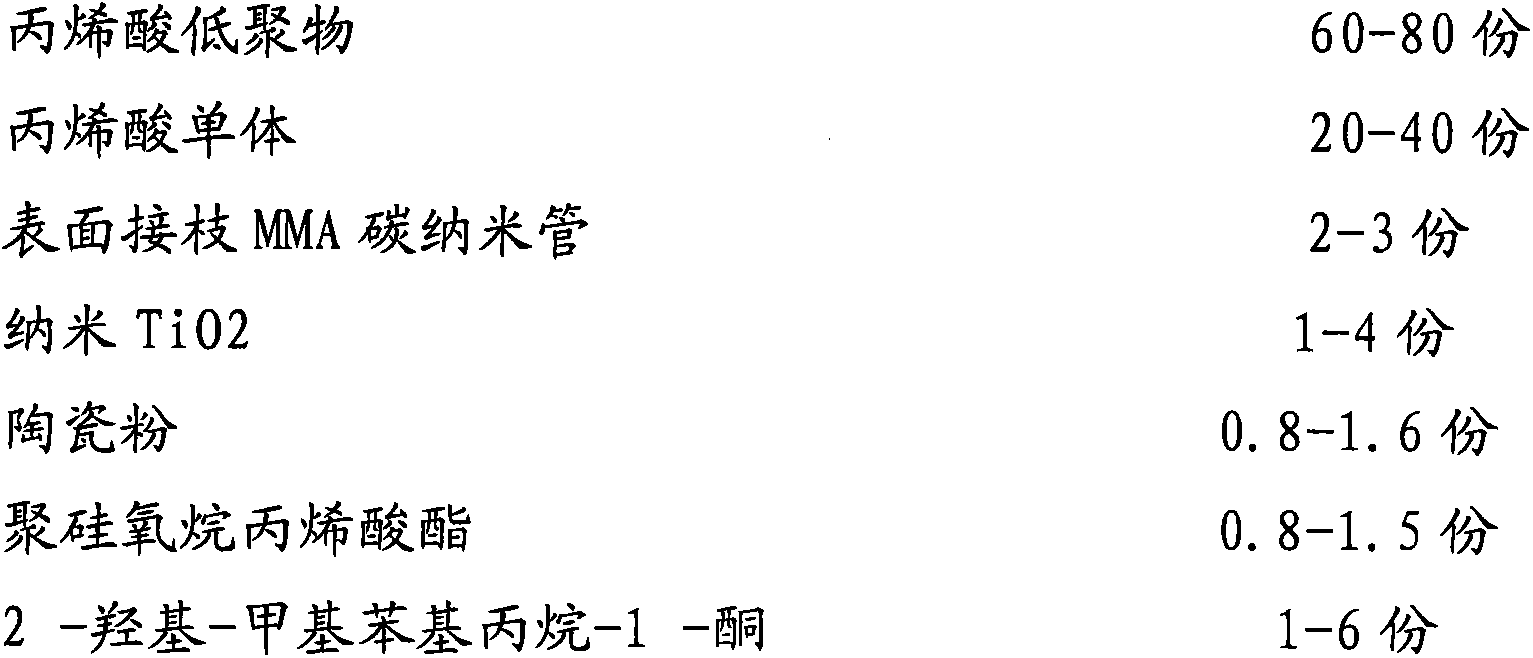

[0014] An antibacterial and antistatic wood-bamboo-plastic floor is characterized in that the floor comprises a wood-bamboo-plastic foam layer, a pattern layer, and a UV coating, wherein the formula of the wood-bamboo-plastic foam layer: 100 parts of polyvinyl chloride (PVC) resin , 20 parts of wood powder, 30 parts of bamboo powder, 6 parts of bamboo charcoal, 8 parts of chlorinated polyethylene (CPE), 8 parts of nano-active calcium carbonate, 6 parts of calcium-zinc composite stabilizer, 10 parts of polyester plasticizer, boric acid 1.5 parts of ester coupling agent, 1.6 parts of AC foaming agent, 0.8 parts of sodium bicarbonate, 6 parts of foam regulator, 0.6 parts of glyceryl stearate, 0.8 parts of polyethylene wax; UV coating UV oil formula: low acrylic acid 80 parts of polymer, 40 parts of acrylic monomer, 3 parts of surface grafted MMA carbon nanotubes, 24 parts of nano-TiO, 1.6 parts of ceramic powder, 1.5 parts of polysiloxane acrylate, 2-hydroxy-methylphenylpropane-1 ...

Embodiment 2

[0016] An antibacterial and antistatic wood-bamboo-plastic floor is characterized in that the floor comprises a wood-bamboo-plastic foam layer, a pattern layer, and a UV coating, wherein the formula of the wood-bamboo-plastic foam layer: 100 parts of polyvinyl chloride (PVC) resin , 10 parts of wood powder, 20 parts of bamboo powder, 4 parts of bamboo charcoal, 6 parts of chlorinated polyethylene (CPE), 4 parts of nano-active calcium carbonate, 5 parts of calcium-zinc composite stabilizer, 6 parts of polyester plasticizer, boric acid 0.8 parts of ester coupling agent, 1.2 parts of AC foaming agent, 0.6 parts of sodium bicarbonate, 4 parts of foam regulator, 0.4 parts of glyceryl stearate, 0.6 parts of polyethylene wax; UV coating UV oil formula: low acrylic acid 60 parts of polymer, 20 parts of acrylic monomer, 2 parts of surface grafted MMA carbon nanotubes, 21 parts of nano-TiO, 0.8 parts of ceramic powder, 0.8 parts of polysiloxane acrylate, 2-hydroxy-methylphenylpropane-1 ...

Embodiment 3

[0018] A method of manufacturing the bacteriostatic and antistatic wood-bamboo-plastic floor of Example 1 and 2 is as follows: weigh according to the formula ratio of the wood-bamboo-plastic foam layer, then add them together to a high-speed mixer for hot mixing and stirring until 110°C, put in cold mixing, stirring and cooling At 40°C, add the extruder into the extruder for skin foaming and vacuum setting to form a wood-bamboo-plastic foam layer. On the wood-bamboo-plastic foam layer, thermally transfer the patterned film, and heat roll on the patterned film to form a three-dimensional Pattern structure, then coating UV oil on it, UV curing, cutting, punching, packaging, and storage; UV oil is prepared by adding dispersing machine ultrasonic dispersion and high-speed magnetic stirring after weighing according to the formula; extruder temperature: 160 -175°C, vacuum degree -0.04--0.06MPa, cooling water temperature ≤40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com