Preparation method for hierarchical pore low-silicate zeolite

A technology of multi-level pores and silicalite, applied in the direction of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, etc., can solve the problems affecting the use efficiency and range, and achieve easy control of products, increase effective utilization rate, Effect of Reducing Diffusion Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 0.1mol organosilane coupling agent N-[3-(trimethoxysilyl)propyl]aniline, dissolve it in 720ml 70% methanol aqueous solution, add 30g after the dissolution is complete, the pore size is 3.5nm, and the BET surface area is 850m 2 / g of pure silicon MCM-41 powder, in a 1500ml three-necked flask, reflux and stir at 100°C for 8 hours, cool to room temperature, wash with absolute ethanol, centrifuge the solid and liquid, and dry at 100°C to obtain surface silanized pure silicon MCM-41 powder.

[0024] Take 1.48g surface silanized pure silicon MCM-41 powder, 2.3g sodium metaaluminate, 2.48g sodium hydroxide, mix with 30ml deionized water at room temperature, stir vigorously for 3h, put it into a stainless steel reaction kettle, 100 ℃ crystallization 1d. The crystallized product is centrifuged for solid-liquid separation, washed with water at room temperature until neutral, dried in an oven at 100°C, and roasted in air at 500-550°C for 5-6 hours to prepare a multi-level por...

Embodiment 2

[0027] Take 0.15mol organosilane coupling agent dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride, dissolve it in 720ml 70% methanol aqueous solution, add 30g pore size 3.5nm after dissolving completely, BET surface area 850m 2 / g of pure silicon MCM-41 powder, in a 1500ml three-necked flask, reflux and stir at 100°C for 8 hours, cool to room temperature, wash with absolute ethanol, centrifuge the solid and liquid, and dry at 100°C to obtain surface silanized pure silicon MCM-41 powder.

[0028] 1.7g of sodium hydroxide, 1.53g of sodium metaaluminate, 20ml of deionized water and 1.5g of silicon dioxide were stirred and mixed uniformly at room temperature, aged at 30°C for 23 hours, and an X-type zeolite directing agent was obtained.

[0029]Take 2.5g of pure silicon MCM-41 powder silanized on the surface, 1.7g of sodium hydroxide, mix well with 20ml of deionized water at room temperature, add 1.53g of sodium metaaluminate, stir for 3 hours, then add 1ml of the abov...

Embodiment 3

[0032] Take 2.5g of pure silicon MCM-41 powder silanized on the surface of Example 2, 1.7g of sodium hydroxide, mix with 20ml of deionized water at room temperature, add 1.53g of sodium metaaluminate, stir for 3h, then add 1ml of Example 2 Prepare the X-type zeolite directing agent, stir at 25°C for 24 hours, put it into a stainless steel tube reactor, crystallize at 65°C for 5 days, centrifuge the crystallized product from solid to liquid, wash it with water at room temperature until it is neutral, and put it in an oven at 100°C Drying and calcining in air at 500-550°C for 5-6 hours will produce multi-order porous X-type zeolite.

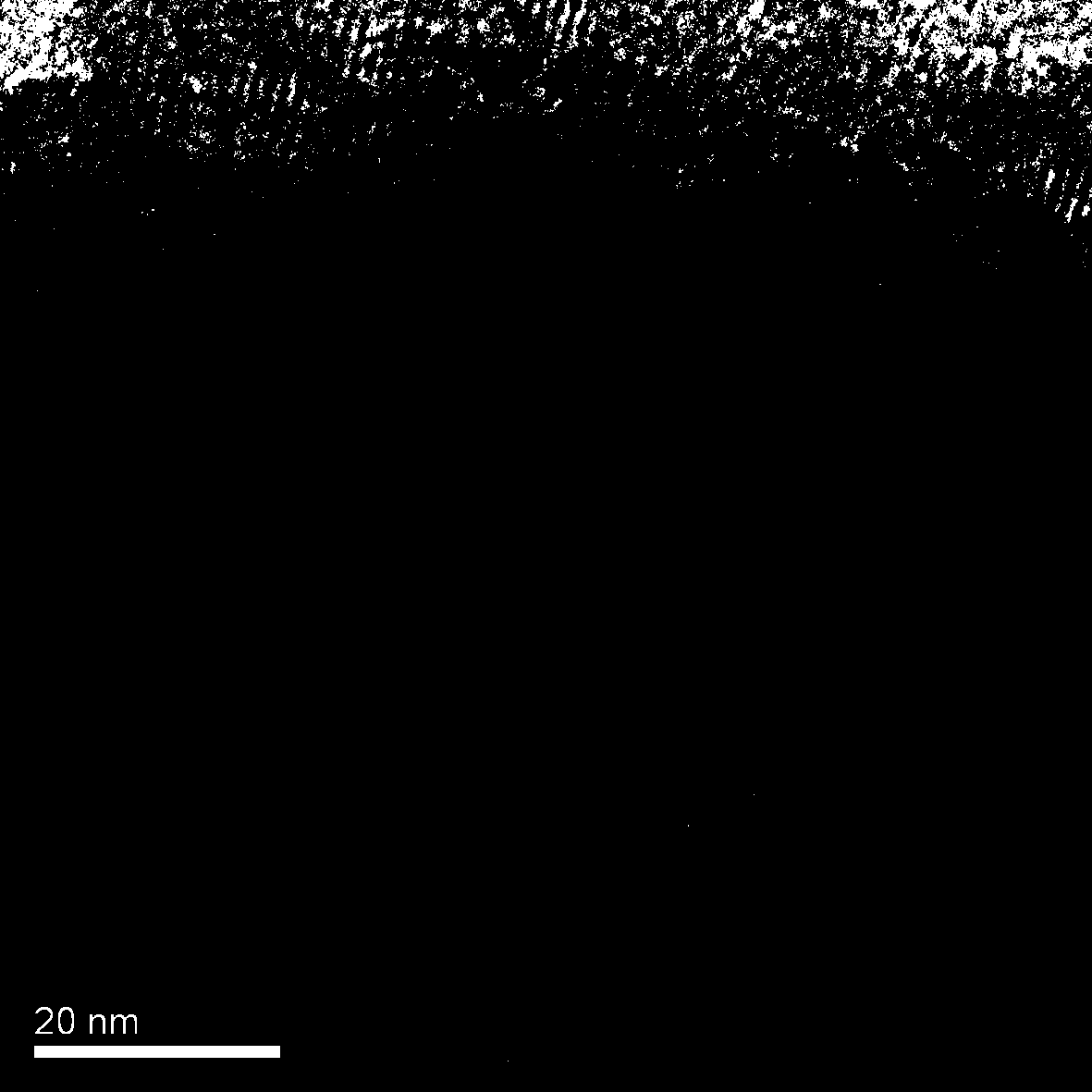

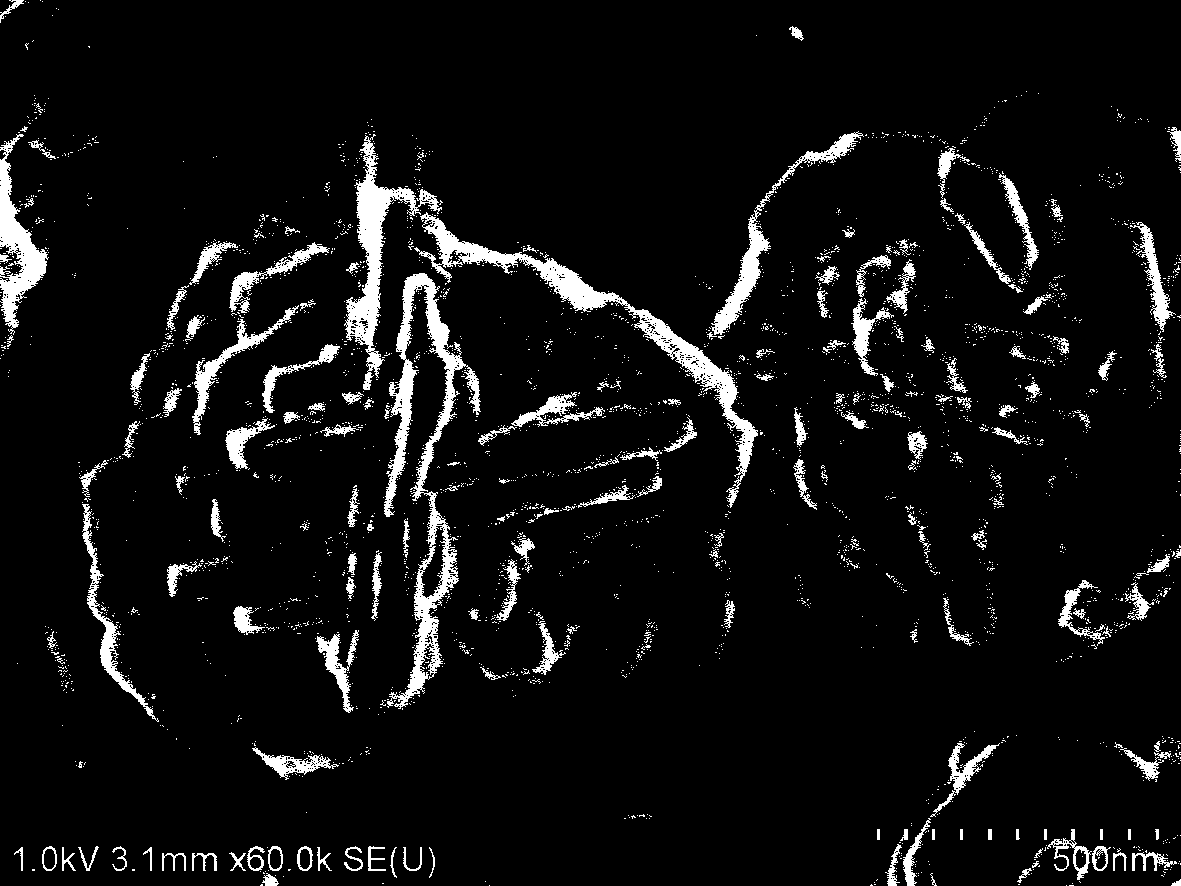

[0033] Product N 2 The adsorption-desorption isotherm shows the mesopore characteristics of the product, and the BET specific surface area is 765m 2 / g, of which the specific surface area is 217m 2 / g, the mesopore volume is 0.31mL / g; the aggregate diameter is about 1.0-1.1μm, the nano-flaky grains are 350-400nm long and 50-100nm wide, and the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com