Production method of ethylene propylene diene monomer self-adhesion water-resistant coiled material

A technology of EPDM rubber and self-adhesive waterproof membrane, which is applied to other rubber adhesives, adhesives, adhesive types, etc., can solve the problems of poor cost performance and bonding of vulcanized waterproof membranes. Problems such as high price, achieve the effect of improving waterproof performance, expanding adaptability, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

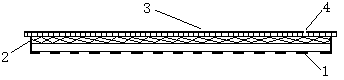

Image

Examples

Embodiment 1

[0038]First, 20 parts of butyl rubber JSR268, 10 parts of the first modifier SEBS, 0.5 parts of antioxidant 1010, 0.5 parts of antioxidant 168 and 0.5 parts of aminosilane coupling agent were added to the internal mixer, at 150 ° C Mix for 8 minutes, make it evenly mixed, discharge and filter to make the mixed masterbatch; then pack the mixed masterbatch with an open mill, thin pass each 3 times, and cut into block mixed masterbatch; Add 25 parts of naphthenic rubber oil, 31.5 parts of block mixing masterbatch, 40 parts of terpene tackifying resin and 3.5 parts of second modifier into the stirring and mixing reaction device and stir and mix at 180°C for 60 A composite modified butyl pressure-sensitive self-adhesive is made after 10 minutes; finally, a hot-melt pressure-sensitive adhesive coating machine is used to fully coat the 0.5mm composite modified butyl pressure-sensitive self-adhesive on the EPDM rubber vulcanized waterproof The main layer of the coil is covered with a ...

Embodiment 2

[0041] Example 2. First, 22 parts of butyl rubber SB4268, 10 parts of the first modifier SIS, 0.2 parts of antioxidant 1010, 0.3 parts of antioxidant 168 and 1 part of monoalkoxy pyrophosphate ester titanate Add the joint agent into the internal mixer, and banbury at 130°C for 7 minutes, make it evenly mixed, discharge the glue and filter to make the mixed masterbatch; then use the open mixer to pack the mixed masterbatch, thin pass each 2 times, cut into block mixing masterbatch; 30 parts of aromatic rubber oil, 33.5 parts of block mixing masterbatch, 10 parts of 138 rosin resin, 10 parts of terpene resin and 6.5 parts of second modifier, etc. Add it into the stirring and mixing reaction device, stir and mix at 160°C for 30 minutes to make a composite modified butyl pressure-sensitive self-adhesive adhesive; finally use a hot-melt pressure-sensitive adhesive coating machine to coat 0.4mm The pressure-sensitive self-adhesive adhesive is fully coated on the main layer of the EP...

Embodiment 3

[0046] Example 3. First, 20 parts of butyl rubber SB4268, 10 parts of the first modifier SIS, 0.2 parts of antioxidant 1010, 0.3 parts of antioxidant 168 and 0.2 parts of monoalkoxy pyrophosphate ester titanate Add the joint agent into the internal mixer, and banbury at 130°C for 7 minutes, make it evenly mixed, discharge the glue and filter to make the mixed masterbatch; then use the open mixer to pack the mixed masterbatch, thin pass each 2 times, cut into block mixing masterbatch; add 30 parts of aromatic rubber oil, 33.5 parts of block mixing masterbatch, 10 parts of petroleum resin, 20 parts of terpene resin and 1 part of second modifier Stir and mix in the mixing reaction device at 160°C for 30 minutes to make a composite modified butyl pressure-sensitive self-adhesive adhesive; finally use a hot-melt pressure-sensitive adhesive coating machine to press the Sensitive self-adhesive is fully coated on the main layer of EPDM rubber vulcanized waterproof membrane, and covere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com