Nano silver polyester biodegradable preservative film, preparation and application thereof

A biodegradable silver polyester technology, applied in the field of polymers, can solve the problems of inability to solve the balance of hydrophobicity and hydrophilicity, inconvenient large-scale production and processing, and uneven degradation of degradable films, so as to achieve good biodegradable performance and comprehensive Low cost, uniform and thorough degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

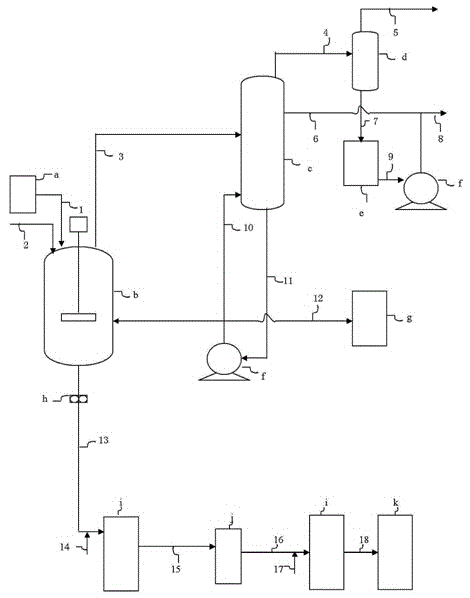

[0061] 1) With respect to 1.00 mol of terephthalic acid, the slurry mixed with 4.50 mol of 1,4-butanediol, 1.5 mol of adipic acid and 0.05 mol of allyl polyethylene glycol ether was mixed at 70°C It is transported to the raw material storage tank a, and enters the continuous supply esterification reactor b through the raw material output pipe line 1. At the same time, a 0.005 mol solution of tetrabutyl titanate at 75° C. is sent from the pipeline 2 . The internal reaction temperature of reactor b is 230°C and the pressure is 80kPa. Collect the esterification water, by-products and the remaining polymerized monomer mixture in the rectification tower container c through line 3. After keeping the system stable, collect the esterification water , when the esterification rate reaches more than 90%, in the reactor b, continue to transport the 75°C tetrabutyl titanate solution from the pipeline 2 to the reactor b, and reduce the pressure to 5500Pa, and continue the reaction for 3 hou...

Embodiment 2

[0070] With respect to 1 mol of terephthalic acid, 1.1 mol of adipic acid was used, and the others were the same as in Example 1.

[0071] The biodegradability test result of gained copolyester film is as follows:

[0072] .

[0073] Tensile strength: transverse 155Mpa, longitudinal 142Mpa; nominal strain at break: transverse 920%, longitudinal 701%; right-angle tear strength: transverse 120N / cm; longitudinal 90N / cm; self-adhesiveness: 140N / ㎝2.

[0074] The antibacterial film has an antibacterial effect on Escherichia coli, and the antibacterial rate is 90%.

Embodiment 3

[0076] With respect to 1 mol of terephthalic acid, 2 mol of adipic acid was used, and the others were the same as in Example 1.

[0077] The biodegradability test result of gained copolyester film is as follows:

[0078] .

[0079] Tensile strength: transverse 125Mpa, longitudinal 116Mpa; nominal strain at break: transverse 790%, longitudinal 596%; right-angle tear strength: transverse 90N / cm; longitudinal 60N / cm; self-adhesiveness: 160N / ㎝2.

[0080] The antibacterial film has an antibacterial effect on Escherichia coli, and the antibacterial rate is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com