Preparation method of fosthiazate microcapsule suspension

A technology of microcapsule suspending agent and thiazophosphine, which is applied in the fields of botanical equipment and methods, biocides, biocides, etc., can solve the problems of reducing the control effect of pesticides, short duration of effect, etc. Long release period, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

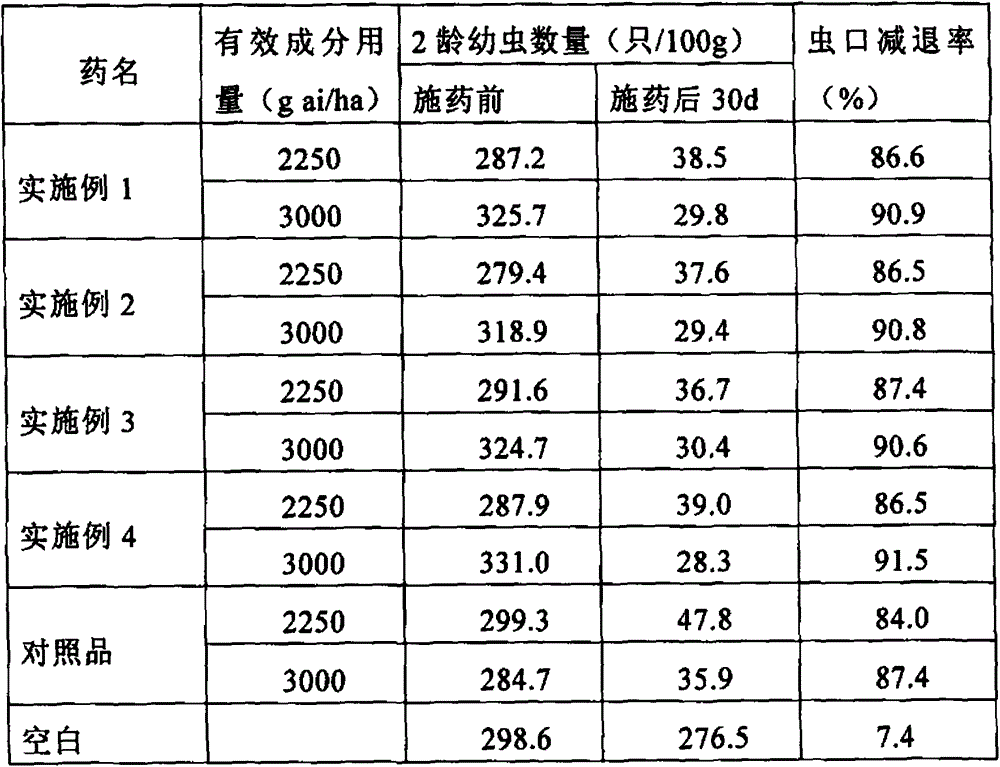

Embodiment 1

[0026] 1. Preparation of capsule material

[0027] Take by weighing 40.0kg urea and 97.3kg mass ratio concentration be the formaldehyde (n urea:n formaldehyde=1:1.8) of 37% and mix, use NH 4 Adjust the pH value of the Cl solution to 8-8.5, and slowly heat it to 70°C, and continue to stir for 1 hour under heat preservation to obtain a viscous and transparent solution substance. Add 194.6kg of distilled water to prepare a urea-formaldehyde prepolymerization with a mass ratio concentration of 28%. The aqueous solution of the substance is obtained as the capsule material.

[0028] 2. Formation of microcapsules

[0029] Add 3 to 5 drops of tributyl phosphate to 45 kg of thiazole phosphorus crude oil at room temperature, stir evenly and add to a container containing 45 kg of capsule material, then add 2.5 kg of styrene-maleic anhydride sodium salt with a mass ratio concentration of 30%, 2.5kg sodium alginate and 2.5kg sodium polyacrylate, 1500r·min -1 Stir for 20min to form a sta...

Embodiment 2

[0031] Add urea and formaldehyde (the molar ratio is about 1:1.5) into a three-neck flask equipped with a stirring device, and adjust the pH value of the solution to about 8-9 with sodium hydroxide solution. The temperature is raised to 70-80° C. to obtain a stable urea-formaldehyde resin prepolymer, and the amount of distilled water is twice that of formaldehyde to prepare a capsule material with a mass ratio concentration of 25-35%. Take 25g of thiazole phosphorus crude oil and 40g of capsule material into a 250ml three-necked flask, add 0.5g of octylphenol polyoxyethylene ether, 3g of sodium dodecylbenzene sulfonate, 1.5g of polyvinyl alcohol, 1300r min -1 Stir for 25 minutes to form a stable O / W emulsion; then reduce the speed to 600-1300r min -1 Add 4% (mass ratio) of acetic acid in batches within 60 minutes to adjust the pH value to 2.5, and polycondensation reaction occurs; gradually raise the temperature to 40-60°C to solidify the capsule wall; add sodium hydroxide to ...

Embodiment 3

[0033]Get 100 g of gelatin, add distilled water, and prepare a gelatin aqueous solution with a mass ratio concentration of 10%. Take 25g of gelatin aqueous solution, keep the temperature at 40°C, pH=7; mix 15g of thiazolphos, 8g of Tween-20, and 8g of diethylamine evenly, and add it to the gelatin aqueous solution under stirring. Continue to keep the temperature at 40°C, stir and add 25g of gum arabic aqueous solution with a mass ratio concentration of 10% to mix, stir and add acetic acid solution with a concentration of 10% until the pH value of the mixed system is 4.0, at this time, the viscosity of the sol increases gradually. become opaque. As a result, the original oil-in-water two-phase system was transformed into a coacervated phase that gathered around thiazophos and formed a coating. After the condensed phase is formed, let the mixture system leave the water bath to cool naturally to room temperature, and then cool the system to 5-10°C with an ice-water bath, keep it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com