Internal micro-channel heat sink

A channel and internal micro technology, applied in the direction of laser components, electrical components, lasers, etc., can solve the problem of poor oxygen-free copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

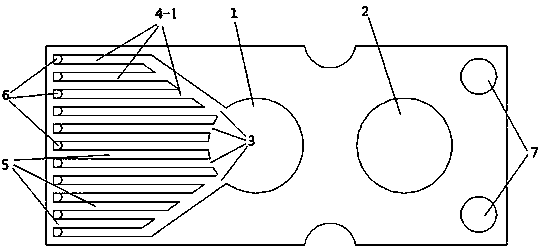

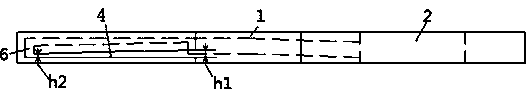

Embodiment 1

[0042] The manufacturing method of the structure in this example is a narrow channel heat sink integrally formed by additive manufacturing technology. The cooling water enters the water inlet channel 4 between the channel walls 5 sequentially from the water inlet hole 1 through the water inlet channel hole 3, the water inlet channel, and then The bonding front end of the heat sink chip enters the water outlet channel 9 through the reverse water hole 6, and after passing through the confluence channel 10, it enters the water outlet hole 2 through the water outlet channel hole 8, thereby completing a cycle of refrigeration. The reasons for increasing the number of inlet and outlet passages 4 and making the passage walls as long as possible are to increase the heat exchange area as much as possible, reduce the velocity of liquid movement, and improve heat exchange efficiency. The channel height h3 at the reverse water hole 6 of the water outlet channel 9 is greater than the channe...

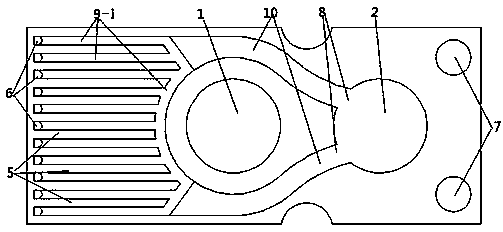

Embodiment 2

[0044] The manufacturing method of the structure in this example is a narrow channel heat sink integrally formed by additive manufacturing technology. The cooling water enters the water inlet channel 4 between the channel walls 5 sequentially from the water inlet hole 1 through the water inlet channel hole 3, the water inlet channel, and then The bonding front end of the heat sink chip enters the water outlet channel 9 through the reverse water hole 6, and after passing through the confluence channel 10, it enters the water outlet hole 2 through the water outlet channel hole 8, thereby completing a cycle of refrigeration. The reasons for increasing the water inlet and outlet channels and making the channel walls as long as possible are to increase the heat transfer area as much as possible, reduce the liquid movement speed, and improve the heat transfer efficiency. The channel height h3 at the reverse water hole 6 of the water outlet channel 9 is greater than the channel width ...

Embodiment 3

[0049] The manufacturing method of the structure in this example is a narrow channel heat sink integrally formed by additive manufacturing technology. The cooling water enters the water inlet channel 4 between the channel walls 5 sequentially from the water inlet hole 1 through the water inlet channel hole 3, the water inlet channel, and then The bonding front end of the heat sink chip enters the water outlet channel 9 through the reverse water hole 6, and then enters the water outlet hole 2 through the water outlet channel hole 8 after passing through the confluence channel 10, thereby completing a cycle of refrigeration. The reasons for increasing the water inlet and outlet channels and making the channel walls as long as possible are to increase the heat transfer area as much as possible, reduce the liquid movement speed, and improve the heat transfer efficiency. The channel height h3 at the reverse water hole 6 of the water outlet channel 9 is greater than the channel width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com