Aluminum powder surface hydration processing method and application of aluminum powder in preparing Al@Ag nuclear shell composite particle conductive and electromagnetic shielding filler

A technology of hydration treatment and electromagnetic shielding, applied in coating and other directions, can solve the problems of complex process, high cost and large amount of silver, and achieve the effect of simple raw material composition, low cost and low silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

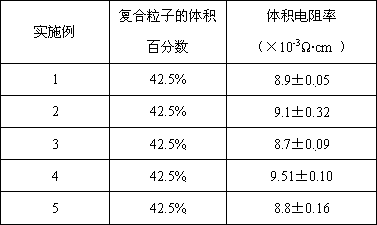

Examples

no. 1 example

[0020] The first embodiment includes: Step 1. Add 40g of aluminum powder in 400mL of deionized water, stir, let it stand for 30 minutes, pour off the supernatant, wash repeatedly until the supernatant has no floating matter, suction filter, and vacuum dry for later use ;

[0021] Step 2. Take 400 mL of a mixed solution of water and ethanol with a volume ratio of 3:1 in a three-necked flask, and heat it in a temperature-controlled oil bath. After controlling the temperature to 72°C, add the above-mentioned aluminum powder and stir for 3 min ;

[0022] Step 3. Add 30 mL of γ-mercapto-propyltrimethoxysilane, stir until uniform, keep the solution temperature at 72°C, react for 4 hours, filter, and vacuum dry for later use;

[0023] Step 4. Prepare the reducing solution, take 22.5 g of glucose, 2 g of potassium sodium tartrate and 500 mL of deionized water, boil for 5 min, cool to room temperature for later use; take 200 mL of reducing solution, and then add 10 g of polyvinylpyrro...

no. 2 example

[0027] The second embodiment includes: Step 1. Add 40g of aluminum powder in 400mL of deionized water, stir, let it stand for 30 minutes, pour off the supernatant, wash repeatedly until the supernatant has no floating matter, filter it with suction, and dry it in vacuum for later use ;

[0028] Step 2. Take 400 mL of a mixed solution of water and ethanol with a volume ratio of 3:1 in a three-necked flask, and heat it in a temperature-controlled oil bath. After controlling the temperature to 74°C, add the above-mentioned aluminum powder and stir for 2 min ;

[0029] Step 3. Add 30 mL of γ-mercapto-propyltrimethoxysilane, stir until uniform, keep the solution temperature at 74°C, react for 4 hours, filter, and vacuum dry for later use;

[0030] Step 4. Prepare the reducing solution, take 22.5 g of glucose, 2 g of potassium sodium tartrate and 500 mL of deionized water, boil for 5 min, cool to room temperature for later use; take 200 mL of reducing solution, and then add 10 g of...

no. 3 example

[0034] The third embodiment includes: Step 1. Add 40g of aluminum powder in 400mL of deionized water, stir, let it stand for 30 minutes, pour off the supernatant, wash repeatedly until the supernatant has no floating matter, suction filter, and vacuum dry for later use ;

[0035] Step 2. Take 400 mL of a mixed solution of water and ethanol with a volume ratio of 3:1 in a three-necked flask, and heat it in a temperature-controlled oil bath. After controlling the temperature to 75°C, add the above-mentioned aluminum powder and stir for 2 min ;

[0036] Step 3. Add 30 mL of γ-mercapto-propyltrimethoxysilane, stir until uniform, keep the solution temperature at 75°C, react for 4 hours, filter, and vacuum dry for later use;

[0037]Step 4. Prepare the reducing solution, take 22.5 g of glucose, 2 g of potassium sodium tartrate and 500 mL of deionized water, boil for 5 min, cool to room temperature for later use; take 200 mL of reducing solution, and then add 10 g of polyvinylpyrrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com