Method for recycling silver and rhenium from invalid ethylene oxide catalyst

A technology of ethylene oxide catalyst and deionized water, which is applied in the direction of improving process efficiency, can solve the problems of high value and must be recycled, and achieves the effects of high recovery rate, clean production process and improved leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

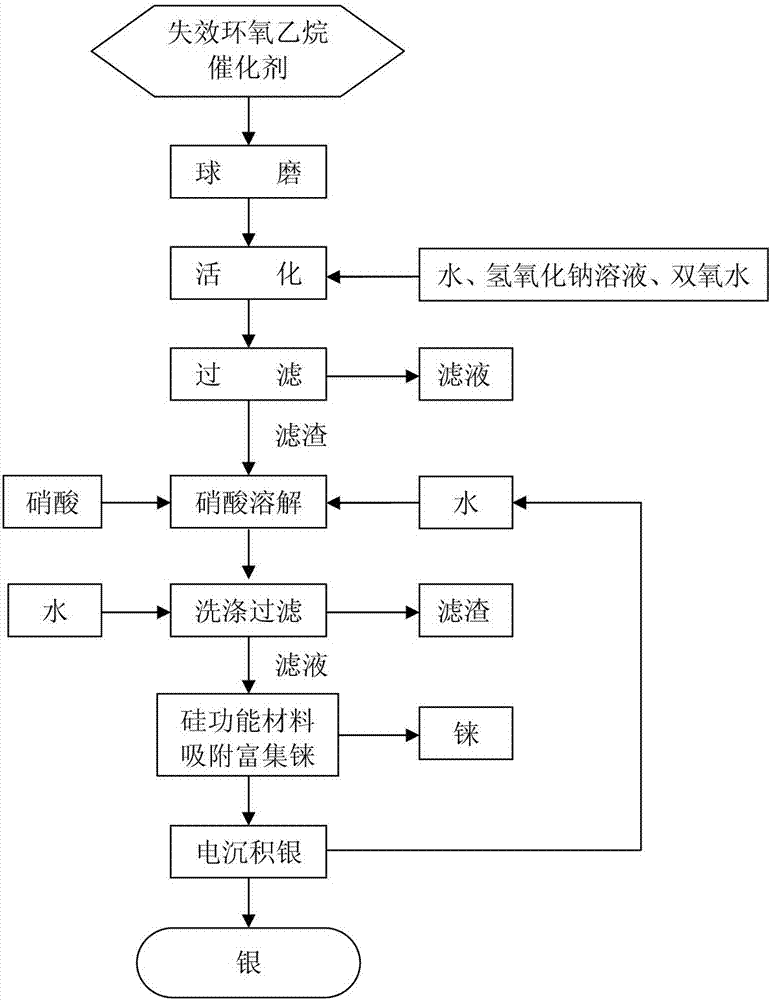

[0035] Such as figure 1 Shown, the method for reclaiming silver and rhenium from spent oxirane catalyst, carries out successively according to the following steps:

[0036] A, ball milling: put the spent ethylene oxide catalyst into a ball mill and grind it into particles with a particle size of 80 mesh;

[0037] B. Activation: Put the invalid ethylene oxide catalyst particles obtained in step A into a titanium reactor, add deionized water, the liquid-solid ratio of deionized water to the invalid ethylene oxide catalyst particles is 2:1, and the liquid The solid ratio is the mass ratio. Stir at a stirring speed of 50 rpm, heat to 50°C, adjust the pH value of the solution to 9 with 5% sodium hydroxide solution, and start adding analytically pure hydrogen peroxide dropwise. The amount of hydrogen peroxide added is invalid. 3% of the mass of the ethylene oxide catalyst, and the reaction time is 60 minutes; the silver and rhenium in the invalid ethylene oxide catalyst will be wra...

Embodiment 2

[0045] The method for reclaiming silver and rhenium from spent oxirane catalyst, carries out successively according to the following steps:

[0046] A, ball milling: Put the spent ethylene oxide catalyst into a ball mill and grind it into particles with a particle size of 120 mesh;

[0047] B. Activation: Put the invalid ethylene oxide catalyst particles obtained in step A into a titanium reactor, add deionized water, the liquid-solid ratio of deionized water to the invalid ethylene oxide catalyst particles is 3:1, and the liquid The solid ratio is the mass ratio. Stir at a stirring speed of 75 rpm, heat to 60°C, adjust the pH value of the solution to 10.5 with 8% sodium hydroxide solution, and start adding analytically pure hydrogen peroxide dropwise. The amount of hydrogen peroxide added is invalid. The mass of the ethylene oxide catalyst is 5.5%, and the reaction time is 120 minutes; the silver and rhenium in the invalid ethylene oxide catalyst will be wrapped by various ad...

Embodiment 3

[0055] The method for reclaiming silver and rhenium from spent oxirane catalyst, carries out successively according to the following steps:

[0056] A, ball milling: Put the spent ethylene oxide catalyst into a ball mill and grind it into particles with a particle size of 160 mesh;

[0057] B. Activation: Put the invalid ethylene oxide catalyst particles obtained in step A into a titanium reactor, add deionized water, the liquid-solid ratio of deionized water to the invalid ethylene oxide catalyst particles is 4:1, and the liquid The solid ratio is the mass ratio. Stir at a stirring speed of 100 rpm, heat to 70°C, adjust the pH value of the solution to 12 with 10% sodium hydroxide solution, and start adding analytically pure hydrogen peroxide dropwise. The amount of hydrogen peroxide added is invalid. 8% of the mass of the ethylene oxide catalyst, and the reaction time is 180 minutes; the silver and rhenium in the invalid ethylene oxide catalyst will be wrapped by various addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com