Preparation method of amorphous nickel-tungsten alloy coating layer

An amorphous nickel and tungsten alloy technology is applied in the field of preparation of amorphous nickel-tungsten alloy coatings, which can solve the problems of easy waveform change, unsuitable coating preparation, expensive equipment, etc. Application prospect and effect of promoting alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

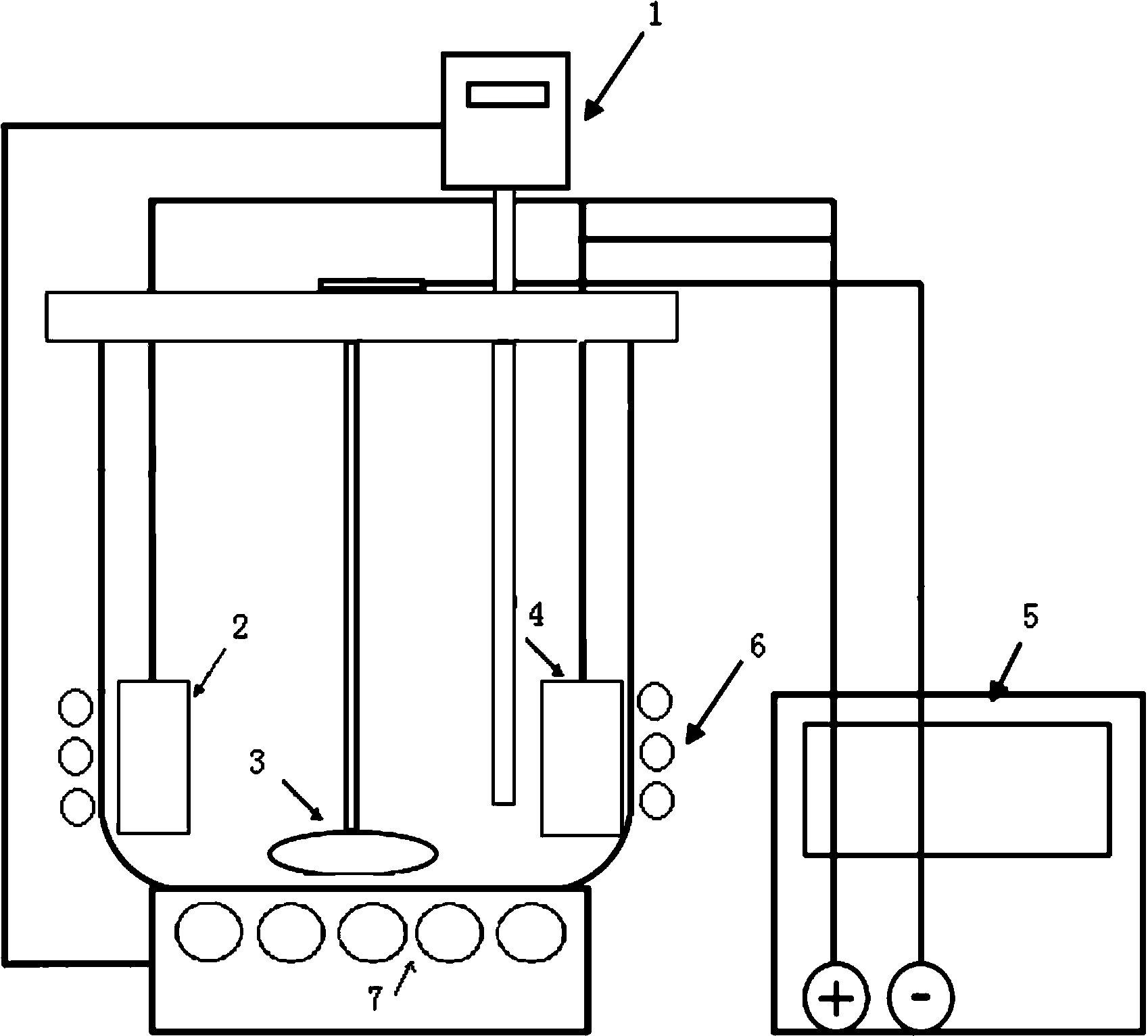

[0029] follow first figure 1 As shown, the DC power supply 5, the ultrasonic motor 6 and the electric heater 7 are connected into a circuit, the anode 2 and the cathode 4 are drawn out from the DC power supply 5, and placed in the reaction vessel, and the thermometer 1 and the stirrer 3 are placed in the reaction vessel near the bottom of the container. Prepare the electroplating solution according to Table 1, pour it into the reaction container, and adjust the pH value of the electroplating solution to 6.9 with dilute hydrochloric acid. Grind and polish the substrate copper sample with 2000# alumina water-resistant sandpaper, ultrasonically clean it for 30 minutes, dry it, and immerse it in a hot alkaline solution with a volume mass of 50 g / L of sodium hydroxide and a volume mass of sodium dihydrogen phosphate of 10 g / L. After 15 minutes, the positive electrode was electrolyzed in a citric acid solution with a mass of citric acid volume of 20 g / L for pickling and activation,...

Embodiment 2

[0034] Prepare the electroplating solution according to Table 2, pour it into the reaction container, and adjust the pH value of the electroplating solution to 6.9 with dilute hydrochloric acid. Grind and polish the substrate copper sample with 2000# alumina water-resistant sandpaper, ultrasonically clean it for 60 minutes, dry it, and immerse it in a hot alkaline solution with a volume mass of 20 g / L of sodium hydroxide and a volume mass of sodium dihydrogen phosphate of 5 g / L. After 10 minutes, the positive electrode was electrolyzed in a citric acid solution with a volume mass of 10 g / L for pickling and activation, and the treatment time was 30 s. Then put the substrate copper sample into the electroplating solution at 40°C for electroplating treatment. The treatment conditions are that the ultrasonic power is controlled at 30kHz, the stirring speed is 100r / min, and the DC current density is 0.40A / cm 2 , the plating time is 20min, and the amorphous Ni-W alloy coating is pre...

Embodiment 3

[0039] Prepare the electroplating solution according to Table 3, pour it into the reaction container, and adjust the pH value of the electroplating solution to 7 with dilute hydrochloric acid. Grind and polish the substrate copper sample with 2000# alumina water-resistant sandpaper, ultrasonically clean it for 60 minutes, dry it, and immerse it in a hot alkaline solution with a volume mass of 60 g / L of sodium hydroxide and a volume mass of sodium dihydrogen phosphate of 20 g / L. After 20 minutes, the positive electrode was electrolyzed in a citric acid solution with a mass of citric acid volume of 30 g / L for pickling and activation, and the treatment time was 20 s. Then put the matrix copper sample into the electroplating solution at 68°C for electroplating treatment. The treatment conditions are that the ultrasonic power is controlled at 40kHz, the stirring speed is 300r / min, and the DC current density is 0.40A / cm 2 , the plating time is 30min, and the amorphous Ni-W alloy coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com