Comprehensive utilization technology for titanium dioxide by-product ferrous sulfate

A by-product, titanium dioxide technology, applied in the direction of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of increased energy consumption and labor costs, less mixed combustion, uneconomical, etc., to achieve unique environmental protection superiority and technology The effect of leading, increasing the amount of blended combustion, and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

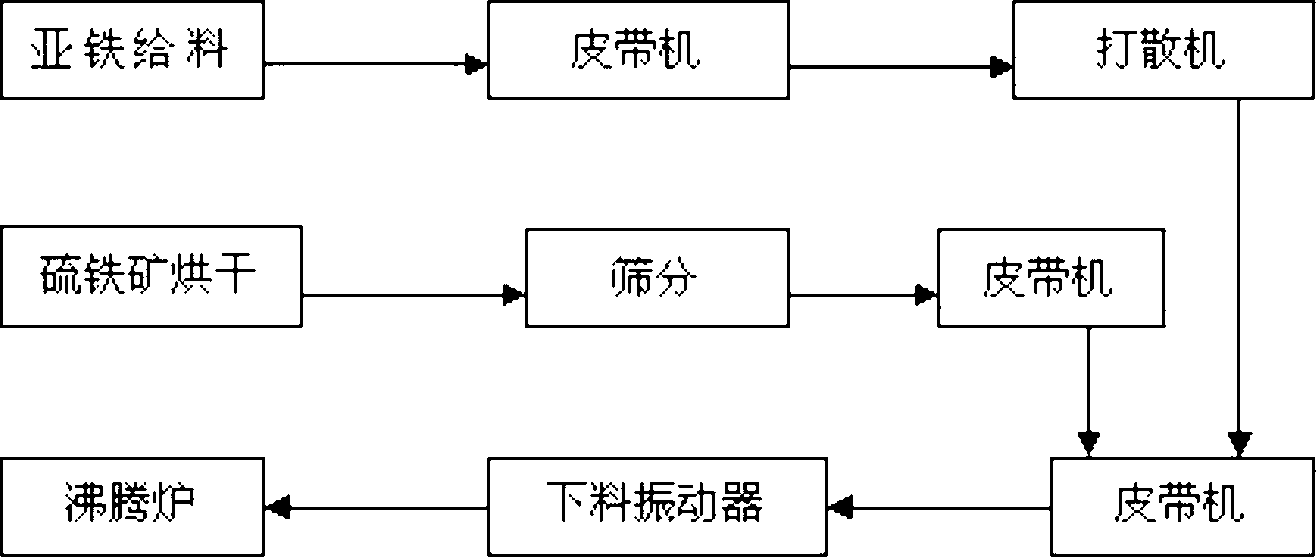

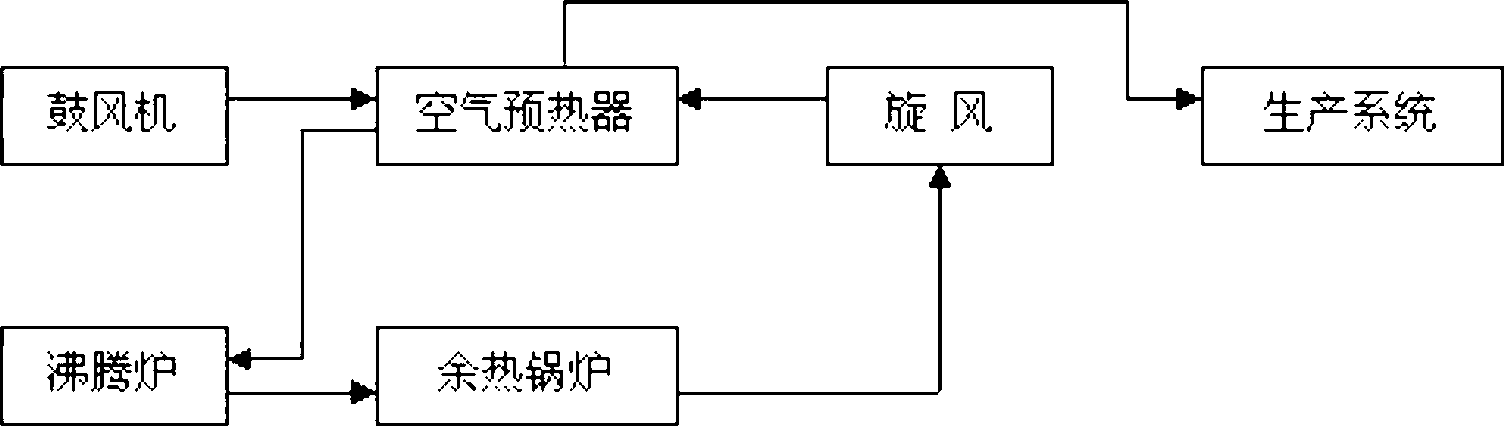

[0024] The comprehensive utilization process of titanium dioxide by-product green vitriol as shown in the figure, the steps are as follows:

[0025] (1) Put the ferrous sulfate heptahydrate onto the ferrous sulfate heptahydrate feeding belt conveyor with a forklift. The feeding belt conveyor of ferrous sulfate heptahydrate is equipped with a feeding automatic control system. Adjust the speed to control the feeding amount; there is a disintegrator at the outlet of the ferrous sulfate heptahydrate feeding belt conveyor to crush large particles of ferrous sulfate heptahydrate;

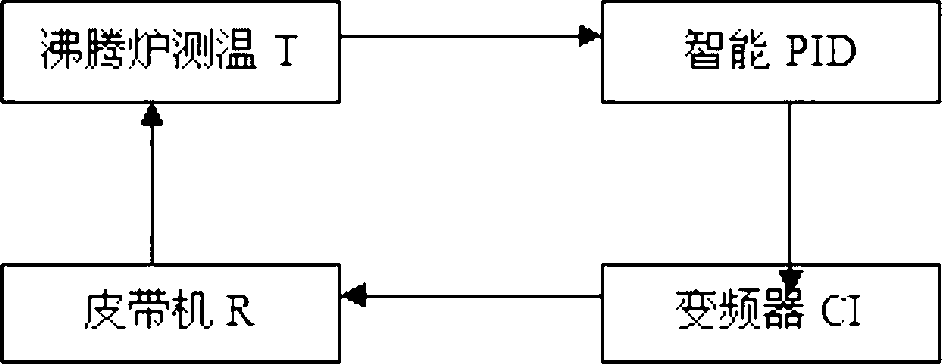

[0026] The speed of the dispersing machine is 300r / min, and the feeding automatic control system includes a fluidized furnace temperature detector, an intelligent regulator and a frequency converter; the fluidized furnace temperature detector is connected to the intelligent regulator, the intelligent regulator is connected to the frequency Iron feeding belt machine connection; input the millivolt signal o...

Embodiment 2

[0030] Titanium dioxide by-product green vitriol comprehensive utilization process step of the present invention is identical with embodiment one, and difference is: the rotating speed of dispersing machine is 290r / min in the step (1); Output the signal of 4mA to the frequency converter after PID adjustment CI terminal; the bottom pressure in the fluidized furnace in the step (3) is 11KPa; the normal temperature air blown into by the blower is heated to 155 ℃ and then sent in the fluidized furnace; the mixed firing amount of the ferrous sulfate heptahydrate is 35%.

Embodiment 3

[0032] Titanium dioxide by-product green vitriol comprehensive utilization process step of the present invention is identical with embodiment one, and difference is: the rotating speed of dispersing machine is 310r / min in the step (1); Output the signal of 20mA to the frequency converter after PID adjustment CI terminal; the bottom pressure in the fluidized furnace in the step (3) is 13KPa; the normal temperature air blown into by the blower is heated to 165 ℃ and then sent in the fluidized furnace; the blending amount of the ferrous sulfate heptahydrate is 40%.

[0033] The design idea of the technical solution of the present invention is as follows:

[0034] 1. The relationship between the amount of mixed ferrous iron and the temperature of the fluidized fluidized furnace;

[0035] The heat energy released by the pyrite during roasting is controlled in a balanced state through the ore blending and the installation of a water tank in the furnace. Because the crystal water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com