A New Method and Device for Surface Processing of Porcelain Polished Tiles

A technology for polishing bricks and brick surfaces, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems that cannot meet the actual production needs, the scraping process cannot meet the requirements, the brick body enters the brick end and bites the edge, etc. problems, to achieve the effect of shortening the production line, reducing production equipment and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

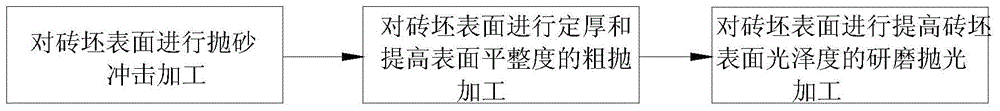

[0042] Such as figure 1 Shown, the invention provides a kind of ceramic polished tile brick surface processing method, it comprises the following steps:

[0043](1) Perform sand blasting impact processing on the surface of the adobe;

[0044] (2) Rough polishing of the brick surface to determine the thickness and improve the surface smoothness;

[0045] (3) Grinding and polishing the surface of the adobe to improve the surface gloss of the adobe.

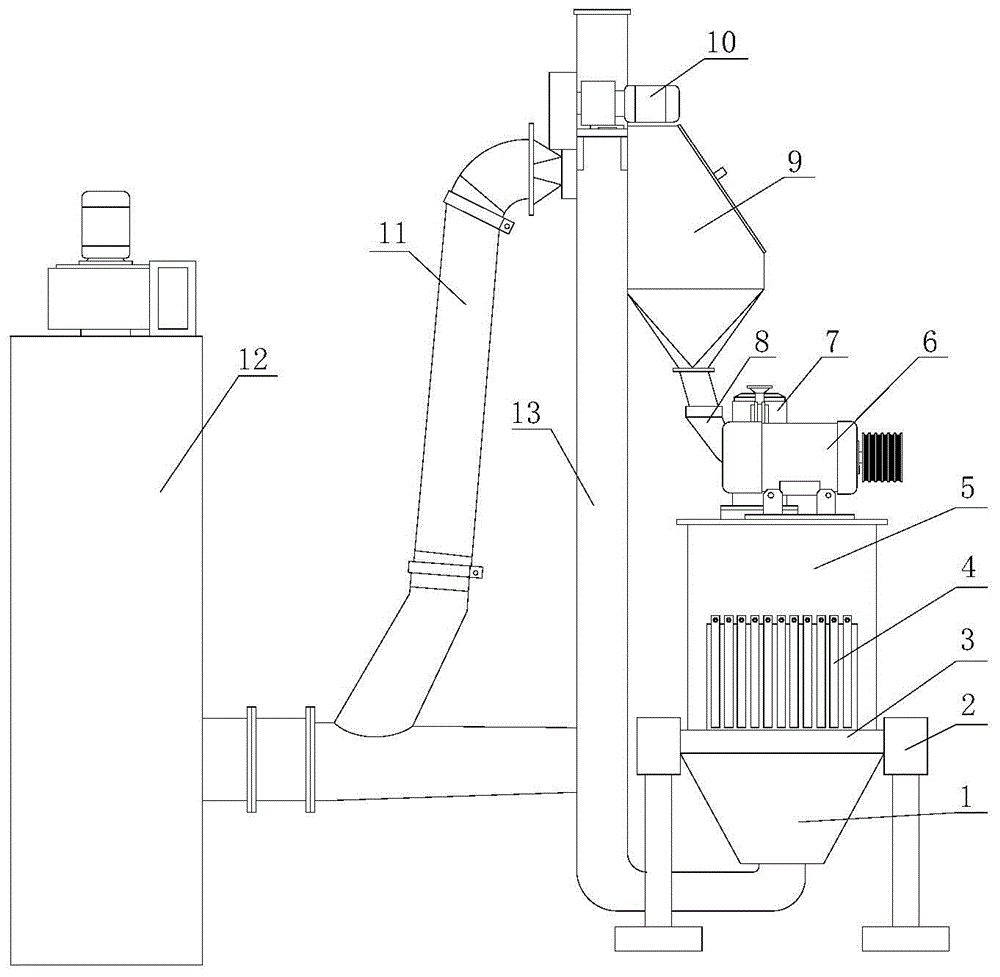

[0046] The blasting impact processing on the surface of the adobe comprises:

[0047] (11) The rotating blades in the blaster throw the steel grit to the surface of the brick, and the steel grit impacts and breaks the surface of the tile;

[0048] (12) The steel grit after impacting and breaking the tiles is collected and re-enters the sand blaster for recycling;

[0049] (13) Repeat step 11 and step 12.

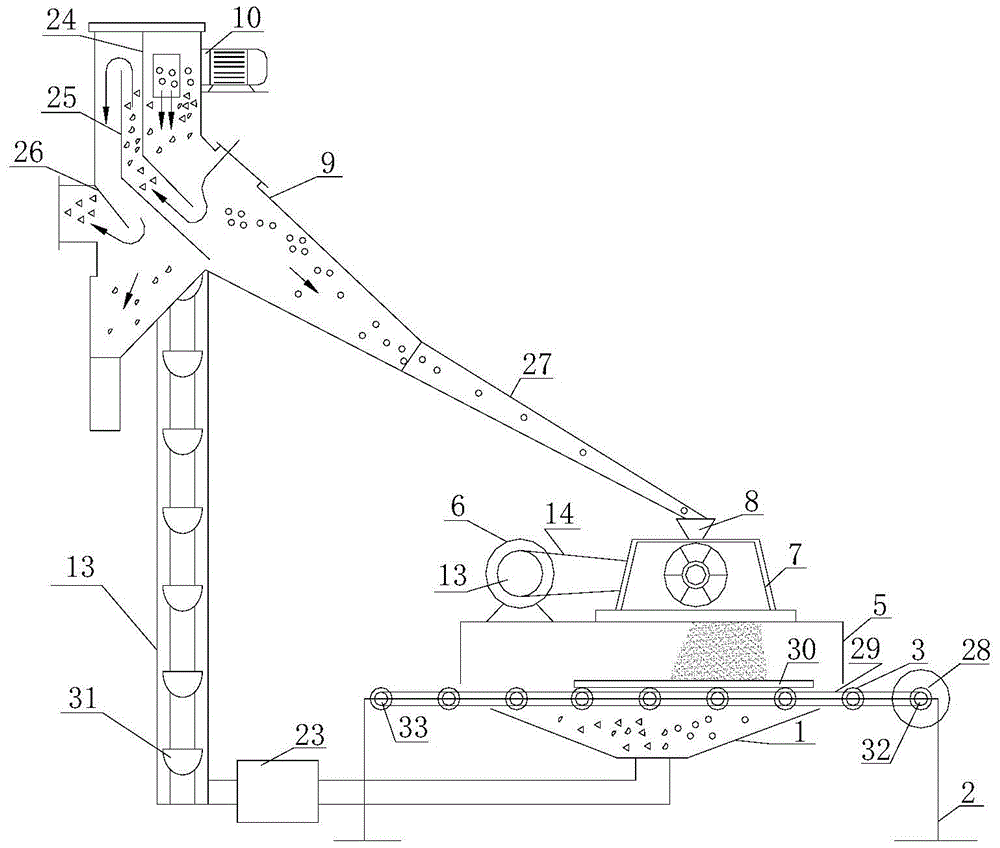

[0050] The rough polishing of the surface of the adobe to improve the flatness of the adobe surface and the grinding and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com