Method for rapid preparation of silicon oxide aerogel microspheres by ordinary pressure drying technology

An atmospheric drying and aerogel technology, applied in the directions of silicon oxide and silicon dioxide, can solve the problems of complex process and long time consumption, and achieve the effect of simple process, short time consumption and shortened preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

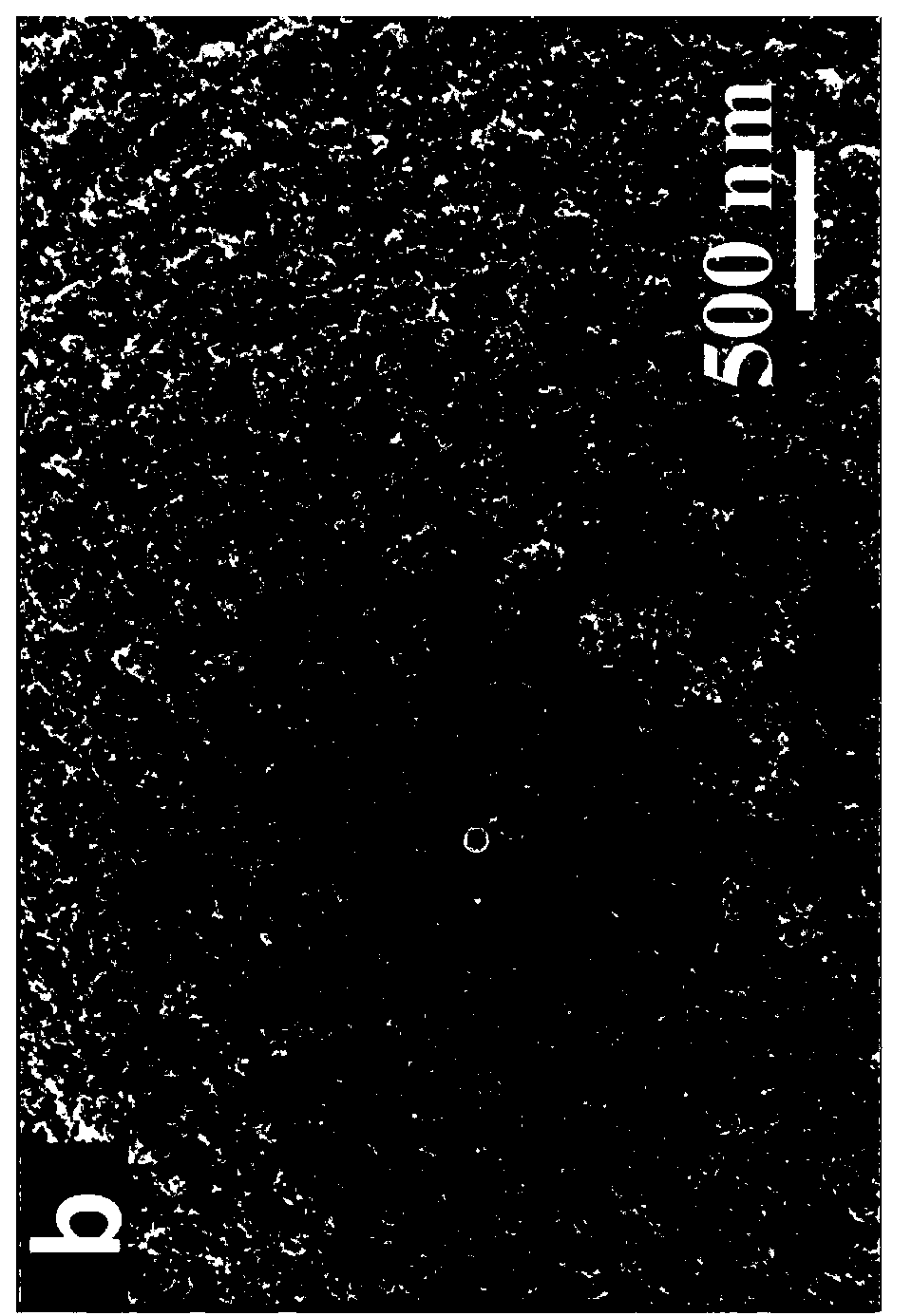

Image

Examples

Embodiment 1

[0028] 1) Prepare a silicic acid solution. In 10mL industrial grade water glass (SiO 2 , 26%), add 25mL of deionized water, and stir well to obtain a diluted sodium silicate aqueous solution. Take 40mL of strongly acidic styrene cation exchange resin, add the above-mentioned diluted sodium silicate aqueous solution to it, stir for 20 minutes, let stand and remove the lower layer of cation exchange resin to obtain a silicic acid solution with pH=2. Subsequently, 2 mL of concentrated nitric acid was added to the silicic acid solution to obtain a strongly acidic silicic acid solution with pH=1.

[0029]2) Prepare a stable inverse emulsion system. Take 10mL of strong acidic silicic acid solution with pH=1, add it to 40mL of cyclohexane, then add 3mL of 0.2mol / L Span 80-cyclohexane solution, and turn the resulting mixture at 1600 rpm Stir for 30 minutes at low temperature to obtain a stable silicic acid solution / cyclohexane inverse emulsion system.

[0030] 3) Simultaneous gela...

Embodiment 2

[0034] 1) Prepare a silicic acid solution. In 10mL industrial grade water glass (SiO 2 , 26%), add 30mL of deionized water, and stir well to obtain a diluted sodium silicate aqueous solution. Take 40 mL of strongly acidic styrene cation exchange resin, add the above-mentioned diluted sodium silicate aqueous solution to it, stir for 15 minutes, let stand and remove the lower layer of cation exchange resin to obtain a silicic acid solution with pH=2.5. Subsequently, 2.5 mL of concentrated nitric acid was added to the silicic acid solution to obtain a strongly acidic silicic acid solution with pH=1.2.

[0035] 2) Prepare a stable inverse emulsion system. Take 10mL of the silicic acid solution prepared in step 1), add it to 40mL of n-hexane, then add 4mL of 0.2mol / L Span 80-n-hexane solution, and put the resulting mixture at a speed of 1800 rpm Stir for 30 minutes to obtain a stable silicic acid solution / n-hexane inverse emulsion system.

[0036] 3) Simultaneous gelation, modi...

Embodiment 3

[0039] 1) Prepare a silicic acid solution. In 10mL industrial grade water glass (SiO 2 , 26%), add 40mL of deionized water, and stir well to obtain a diluted sodium silicate aqueous solution. Take 50 mL of strongly acidic styrene cation exchange resin, add the above-mentioned diluted sodium silicate aqueous solution to it, stir for 15 minutes, let stand and remove the lower layer of cation exchange resin to obtain a silicic acid solution with pH=2.5. Subsequently, 2.5 mL of concentrated nitric acid was added to the silicic acid solution to obtain a strongly acidic silicic acid solution with pH=1.

[0040] 2) Prepare a stable inverse emulsion system. Take 10mL of the silicic acid solution prepared in step 1), add it to 80mL of cyclohexane, then add 3mL of 0.2mol / L Span 60-cyclohexane solution, and turn the resulting mixture at 1800 rpm Stirring at high speed for 30 minutes to obtain a stable silicic acid solution / cyclohexane inverse emulsion system.

[0041] 3) Simultaneous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com