Method for manufacturing resin wheel containing sodium carboxymethylcellulose

A carboxymethyl cellulose and resin grinding wheel technology, applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of easy generation of dust, blue workpiece, large grinding loss, etc., to reduce dust separation and maintain component content. , the effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] To make resin wheel cutting discs:

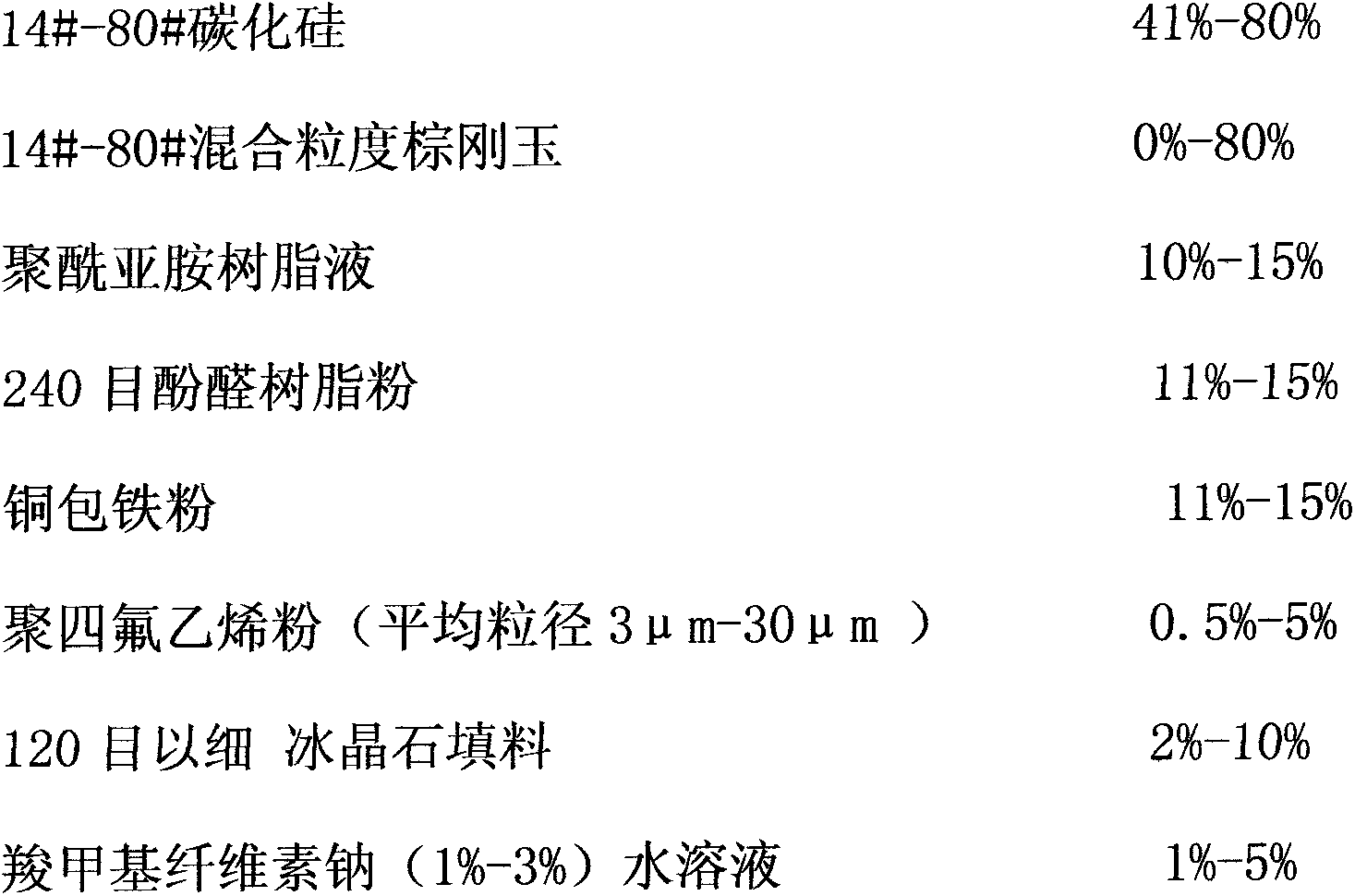

[0022] Select the bonding mixed abrasive with the following ratio, and the ratio is as follows by weight percentage:

[0023]

[0024]

[0025] Its preparation process is as follows:

[0026] Put 24# and 30# brown corundum abrasives into the mixing pot according to the proportion and weight and mix evenly, then add phenolic resin solution, after the corundum abrasives are completely wetted, add cryolite and polytetrafluoroethylene powder in sequence, mix well and then add carboxylate Sodium methyl cellulose aqueous solution, after mixing evenly, add phenolic resin powder and continue mixing until the phenolic resin powder is evenly attached to each abrasive. Then weigh according to the single weight of the cutting piece and then feed the material. Before feeding, put the grinding wheel mesh, spread the material with a scraper, put a grinding wheel mesh after it is flattened, press the platen to form, and then harden.

[0027]...

Embodiment 2

[0029] To make a resin grinding wheel:

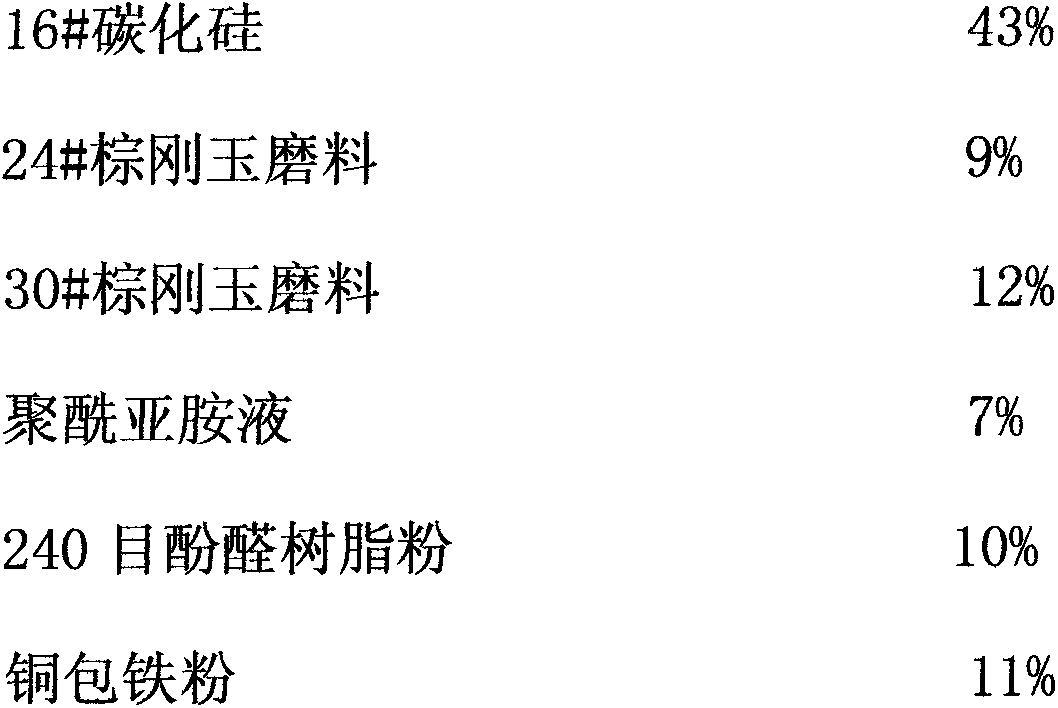

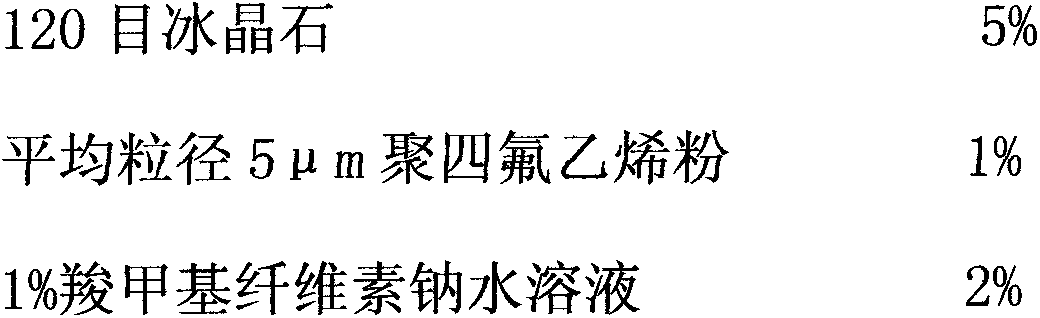

[0030] Resin grinding wheel bonded mixed abrasive formula, the ratio by weight percentage is:

[0031]

[0032]

[0033] Its preparation process is identical with embodiment 1.

[0034] The 356*4.0*25.4 double mesh reinforced resin cutting blade formed by this formula and process can cut prefabricated panels made of reinforced concrete. The minimum loss of one cut is 16mm, and the maximum loss is 17mm. The cutting performance is equivalent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com