Method for manufacturing epitaxy graphene back gate transistor with nitrogen-doped SiC substrate

A graphene back gate and transistor technology, applied in the field of graphene field effect transistors and their preparation, can solve the problems of complex process, easy damage and pollution of graphene, and achieve good electrical properties, expanded operating temperature range, and high electron mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

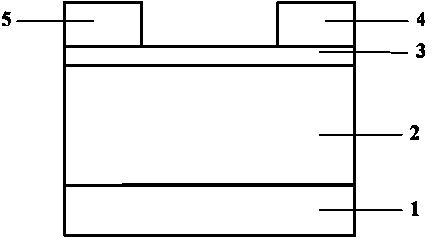

[0016] In the present invention, the gate and dielectric layer of the transistor are integrated with the SiC substrate through the method of implanting nitrogen ions, and then graphene is epitaxially grown on the SiC, and electrodes are plated to form a graphene transistor. details as follows:

[0017] Choose a 1 μm thick SiC substrate and clean it with a standard wafer cleaning method. The specific process is sonication with acetone, absolute ethanol, and deionized water for 5 to 10 minutes, ultrasonic power is 99%, and nitrogen is used after the ultrasonic. The gun will dry it quickly and put it in the sample box.

[0018] Hydrogen etching is used to remove impurities on the surface of the SiC substrate. The radio frequency induction heating furnace is selected as the etching device, the etching power is 400 W, and hydrogen gas (20 sccm, 30 s) is introduced to obtain a flat and uniform SiC substrate.

[0019] The nitrogen ions produced by a semiconductor ion implanter are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com